Experimental Method for Isothermal Local Loading Forming of Titanium Alloys

A technology of isothermal local loading and local loading, applied in the field of thermal processing, can solve the problems of difficult to observe the structure of the specific deformation area, difficult to assemble the mold and the blank, unable to realize the transition area, etc. , the effect of improving the success rate of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

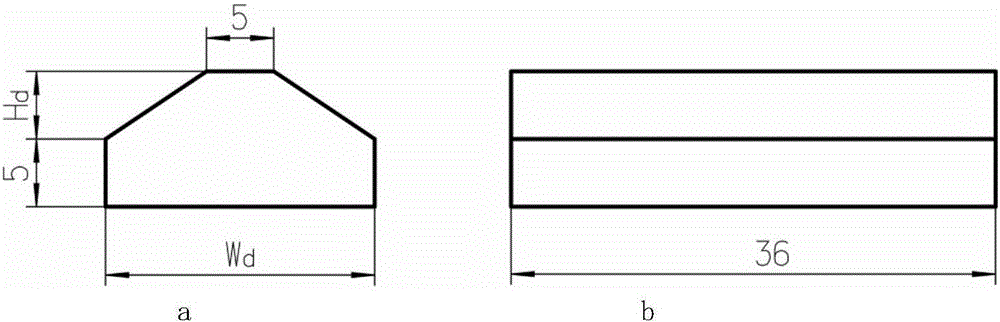

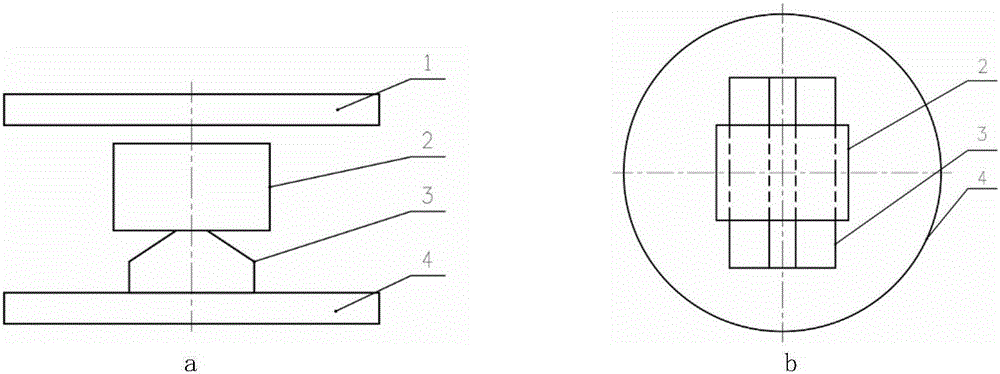

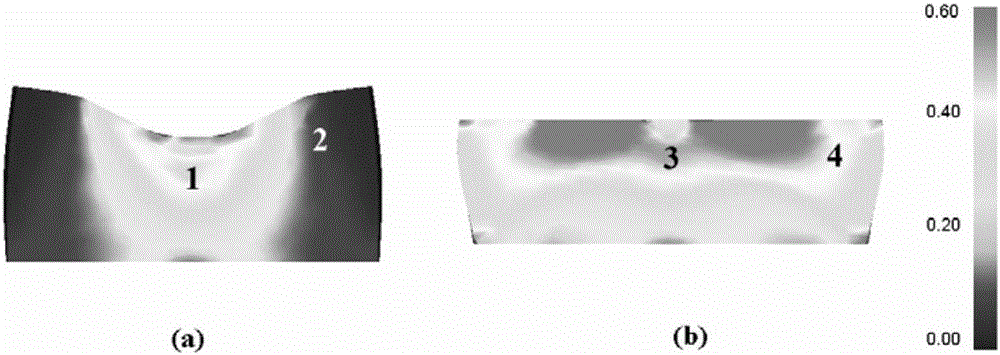

[0032] This embodiment is an experimental method for isothermal local loading forming of titanium alloy.

[0033] In this example, a 20-ton high-temperature mechanical testing machine is used to complete the isothermal local loading forming, and the method of step-by-step loading of the mold and the flat mold at high temperature is used to simulate the isothermal local loading of TA15 titanium alloy in combination with the system design of the blank, mold size and loading reduction. The inhomogeneous deformation characteristics of the forming transition zone are used to realize the simple experimental research on the microstructure evolution of the transition zone.

[0034] The sample used in this embodiment is a cubic blank made of TA15 titanium alloy. The height H of the blank b = 14mm, the length of the shorter side of the horizontal rectangular section of the billet is 18mm. The phase transition point T of the TA15 titanium alloy β is 990°C, the simulation requirements ...

Embodiment 2

[0059] This embodiment is an experimental method for isothermal local loading forming of titanium alloy. In this example, the step-by-step loading method of the mold and the flat die at high temperature is used, combined with the system design of the blank and mold size and the loading reduction, to simulate the uneven deformation characteristics of the transition zone of the isothermal local loading of the TA15 titanium alloy, and to realize the microstructure evolution of the transition zone. Simple experimental research.

[0060] The sample used in this embodiment is a cubic blank made of TA15 titanium alloy. The height H of the blank 2 b = 14mm, the length of the shorter side of the horizontal rectangular section of the billet is 18mm. The phase transition point T of the TA15 titanium alloy β is 990°C, the simulation requirements for the deformation characteristics of the transition zone are: the deformation temperature is T β -80°C, the deformation loading speed is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com