Method for treating gallium electrolysis tail liquid

A treatment method and tail liquid technology, applied in the field of electrolysis tail liquid treatment, can solve problems such as affecting the electrolysis efficiency and product quality, the electrolysis process cannot be carried out normally, affecting the leaching and freezing effects, etc., and achieve good economic and environmental benefits, The effect of good electrolysis and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

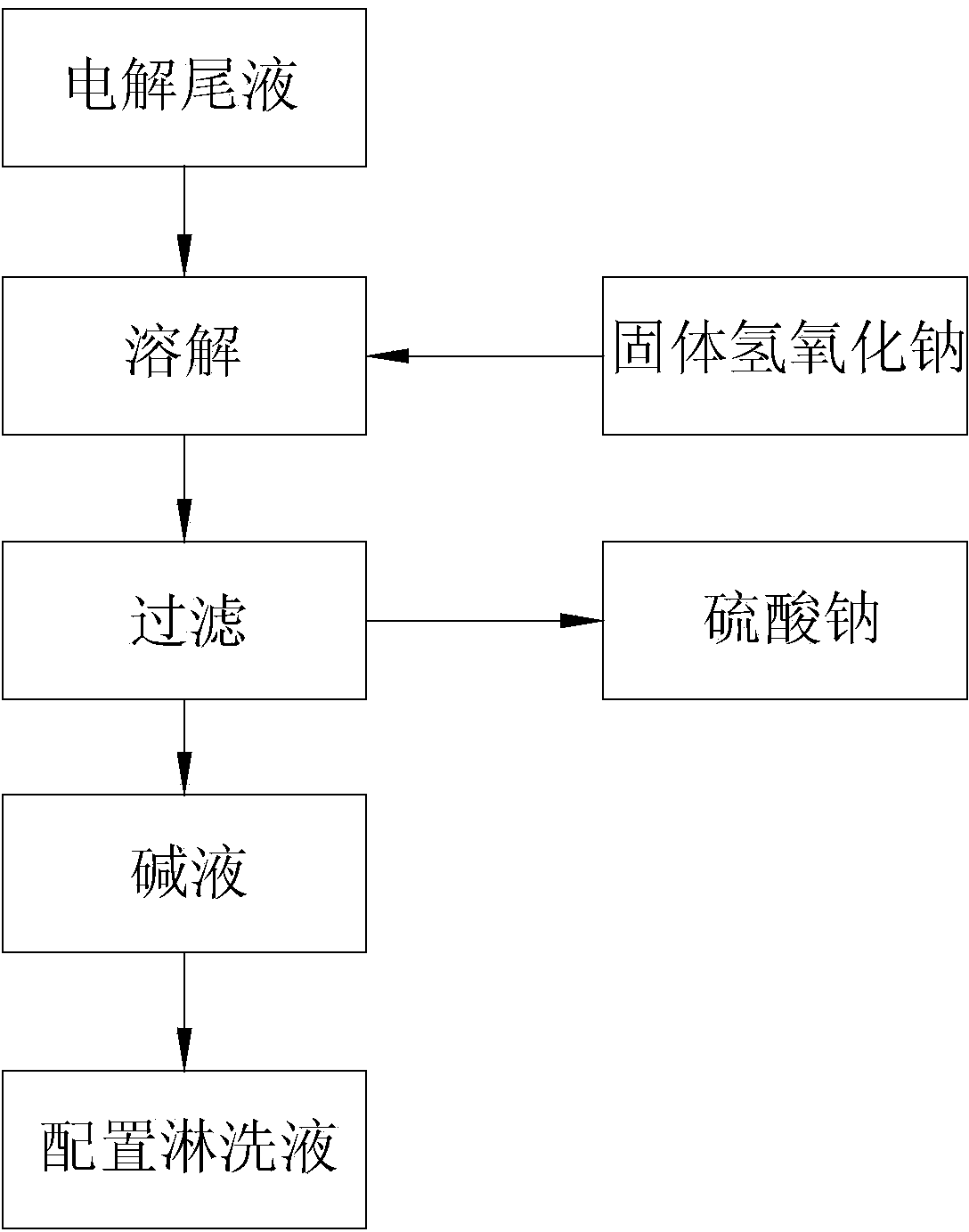

Image

Examples

Embodiment 1

[0024] When the NaOH concentration is 225g / L, Na 2 SO 4 Add 500kg of solid sodium hydroxide to the 2.5m3 gallium electrolytic tail liquid with a concentration of 27g / L, stir and dissolve, and form NaOH with a concentration of 420g / L after filtration, NaOH 2 SO 4 Concentration is 2.2m3 of lye of 6.3g / L. The lye is returned to prepare the eluent and continue to be used to extract gallium. The subsequent processes run stably and the electrolysis is normal.

Embodiment 2

[0026] When the NaOH concentration is 240g / L, Na 2 SO 4 Add 500kg of solid sodium hydroxide to the 2.0m3 gallium electrolytic tail liquid with a concentration of 32g / L, stir and dissolve, and form NaOH with a concentration of 485g / L after filtration. 2 SO 4 Concentration of 3.1g / L lye 1.8m3, this lye is returned to prepare the eluent, and the process of gallium extraction is continued. The subsequent processes run stably and the electrolysis is normal.

Embodiment 3

[0028] When the NaOH concentration is 230g / L, Na 2 SO 4 Add 510kg of solid sodium hydroxide to the 2.2m3 electrolytic tail liquid with a concentration of 35g / L, stir and dissolve, and form NaOH with a concentration of 460g / L after filtration. 2 SO 4 Concentration of 4.5g / L lye 2.0m3, this lye was prepared as a eluent, and the process of gallium extraction was continued. The subsequent processes were stable and the electrolysis was normal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com