Production technology of tyre fabric for tyres

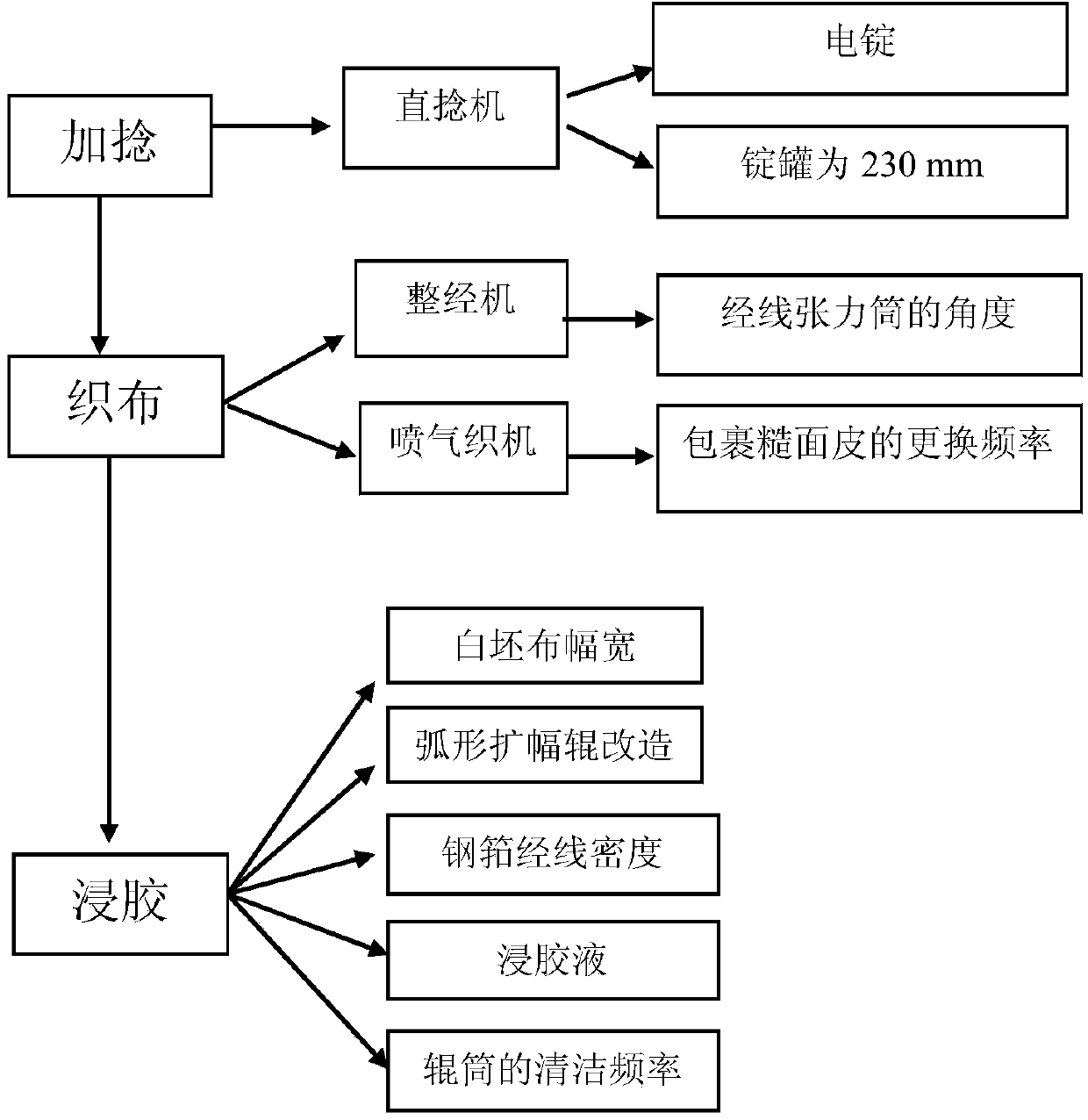

A production process and technology of cord fabric, applied in the direction of fabric elongation, textile material processing, weaving, etc., can solve the problems of defective cord fabric structure, uneven stress, exposed lines on the tire side, etc., to maintain the cord fabric. The effect of physical properties and appearance quality, ensuring the organizational structure, facilitating the mutual penetration of glue and the consistency of tire force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

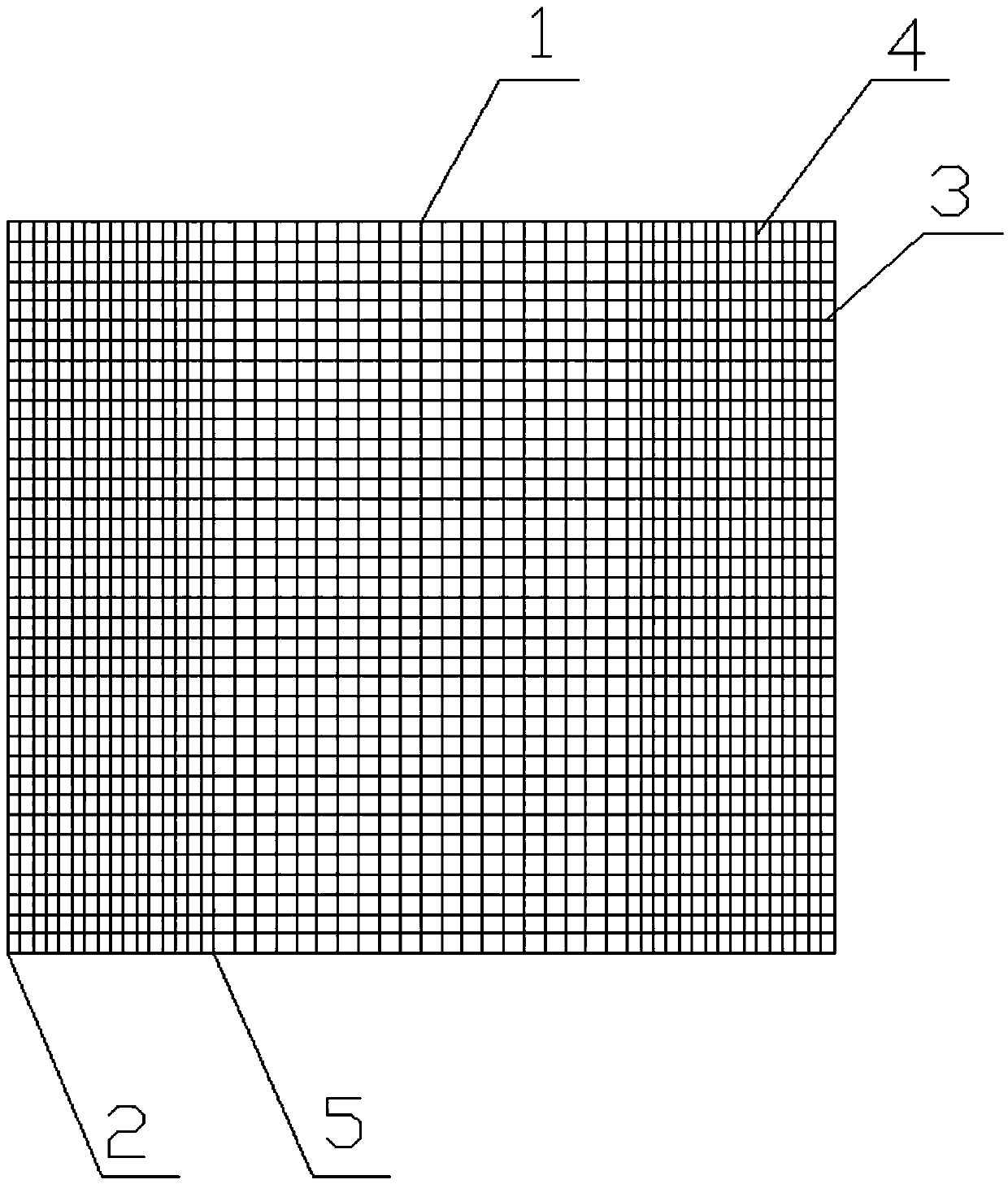

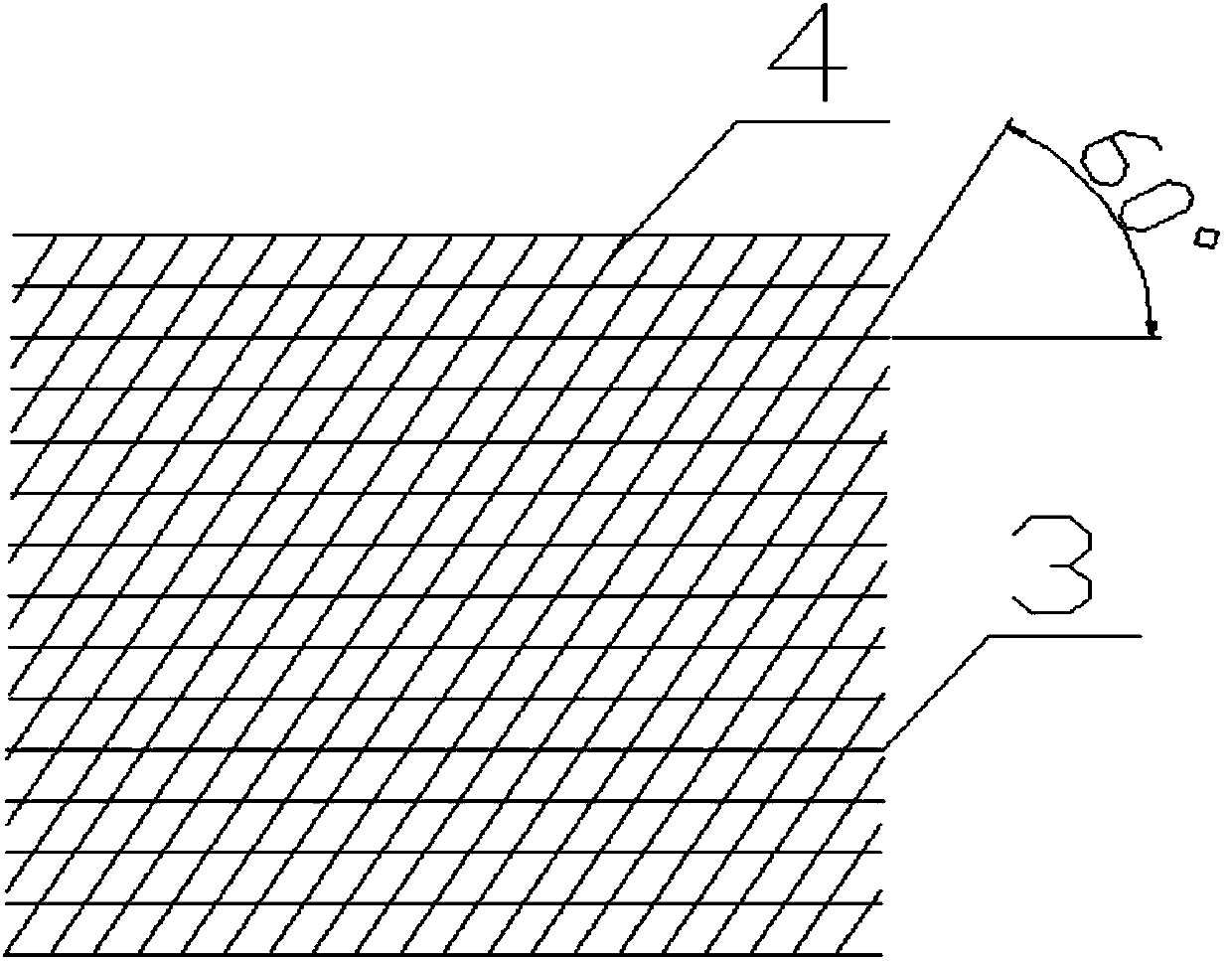

[0019] In the production process of cord fabric, a direct twisting machine with electric spindles as the transmission mode and 230mm spindle pot is adopted, and a multi-warp beam with multiple discs with an outer diameter of 1600mm, an inner diameter of 320mm and a disc edge distance of 2600mm is adopted. The warping machine adopts an air-jet loom with electronic let-off and large-capacity cloth winding device for production; by controlling the white gray fabric width to about 158cm, using the Pexul glue system, the white gray fabric width is designed to be profiled on the reed. 5 Gradually reduce the warp density of the steel reed at 14cm on both sides, continuously and gradually control the warp density, and change the arc expansion roller to a three-finger full-width expander and a half-width expander; the angle of the side warp tension cylinder is higher than that of the middle tension cylinder Small 3°, the replacement frequency of the rough skin on the surface of the let-o...

Embodiment 2

[0021] In the production process of cord fabric, a direct twisting machine with electric spindles as the transmission mode and 230mm spindle pot is adopted, and a multi-warp beam with multiple discs with an outer diameter of 1600mm, an inner diameter of 320mm and a disc edge distance of 2600mm is adopted. The warping machine adopts an air-jet loom with electronic warp let-off and large-capacity cloth winding device for production; by controlling the white gray cloth width to about 155cm, using the Pexul glue system, the white gray cloth width steel reed is designed to be profiled. 5 Gradually reduce the warp density of the steel reed at 14cm on both sides, continuously and gradually control the warp density, and change the arc expansion roller to a three-finger full-width expander and a half-width expander; the angle of the side warp tension cylinder is higher than that of the middle tension cylinder 1°, the replacement frequency of the rough skin on the surface of the let-off r...

Embodiment 3

[0023] In the production process of cord fabric, a direct twisting machine with electric spindles as the transmission mode and 230mm spindle pot is adopted, and a multi-warp beam with multiple discs with an outer diameter of 1600mm, an inner diameter of 320mm and a disc edge distance of 2600mm is adopted. The warping machine adopts an air-jet loom with electronic warp let-off and large-capacity cloth winding device for production; by controlling the white gray cloth width to about 160 cm, using the Pexul glue system, the white gray cloth width steel reed is designed to be profiled on the side of the cloth. 5 Gradually reduce the warp density of the steel reed at 14cm on both sides, continuously and gradually control the warp density, and change the arc expansion roller to a three-finger full-width expander and a half-width expander; the angle of the side warp tension cylinder is higher than that of the middle tension cylinder Small 5°, the replacement frequency of the rough skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com