Transmission type hydraulic pump with crank connecting rod structure

A crank connecting rod and transmission technology, applied in the field of machinery, can solve the problems of asymmetric overall layout of double-acting piston pumps, high price of servo variable axial piston pumps, high manufacturing costs, etc., and achieve compact structure, The effect of large output force and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described in detail below.

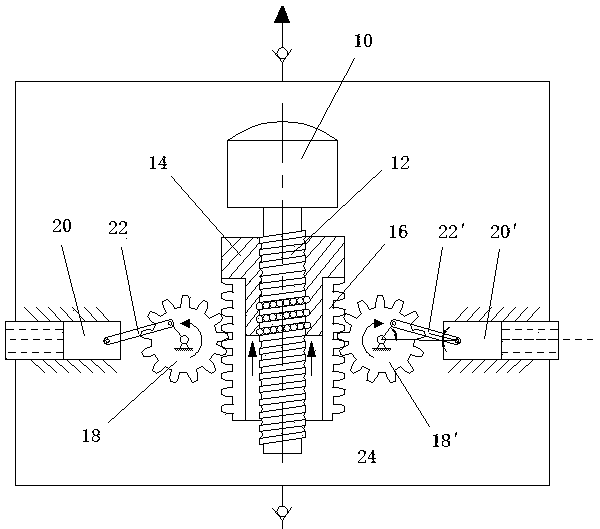

[0020] as attached figure 1 As shown, the transmission hydraulic pump adopting the crank connecting rod structure of the present invention includes a motor 10 . The output shaft of the motor 10 is fixedly connected with a lead screw 12 , and a nut 14 is cooperatingly arranged on the lead screw 12 . A two-sided rack 16 is fixedly connected to the nut 14, and a gear 18 and a gear 18' meshed with the rack 16 are respectively arranged on both sides. Of course, those of ordinary skill in the art can easily think of a rack 16 fixedly connected to the nut 14 according to the thinking of the present invention, and several gears 18 and gears 18' are arranged on the same side of the rack 16; or on both sides of the nut 14 Two separate racks 16 are arranged, and a plurality of gears 18 and gears 18 ′ are arranged along the direction of the racks 16 to realize the function of the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com