Flue gas heating treatment device

A technology for processing equipment and flue gas heating, which is applied in the field of flue gas treatment, can solve the problems of corrosion, damage and economic loss of flue gas heating treatment equipment, and achieve the effects of improving flue gas heating efficiency, compact structure, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

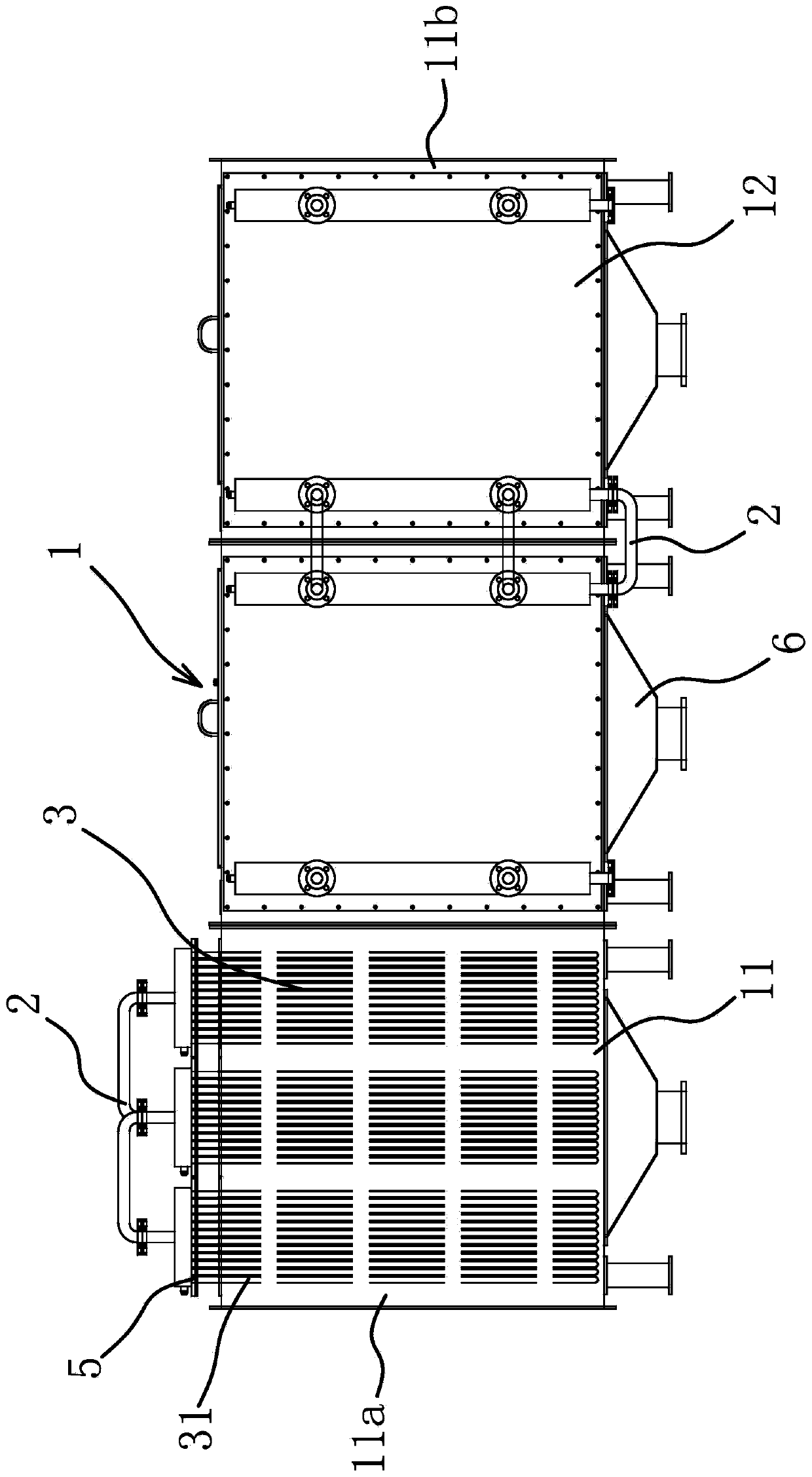

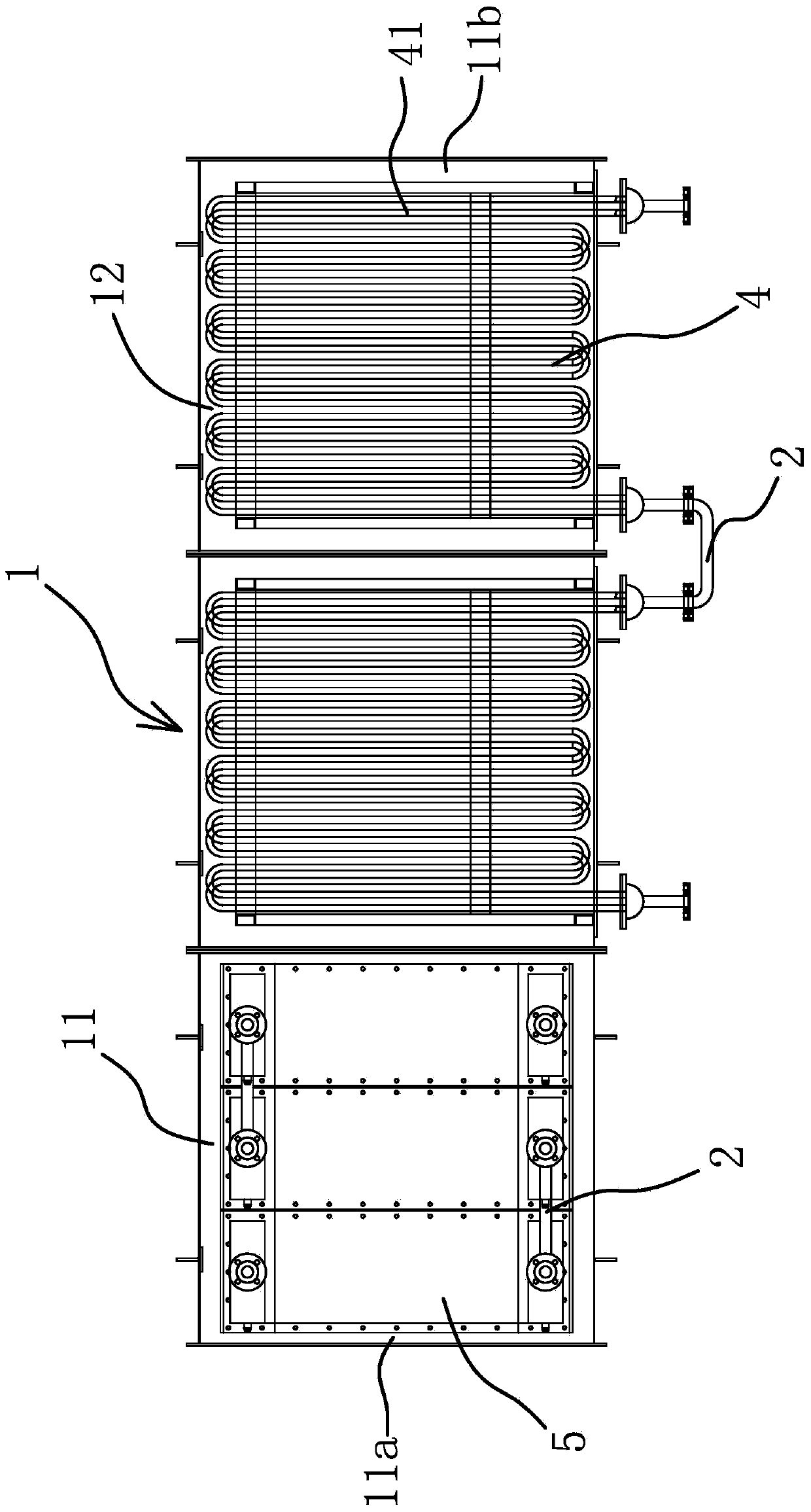

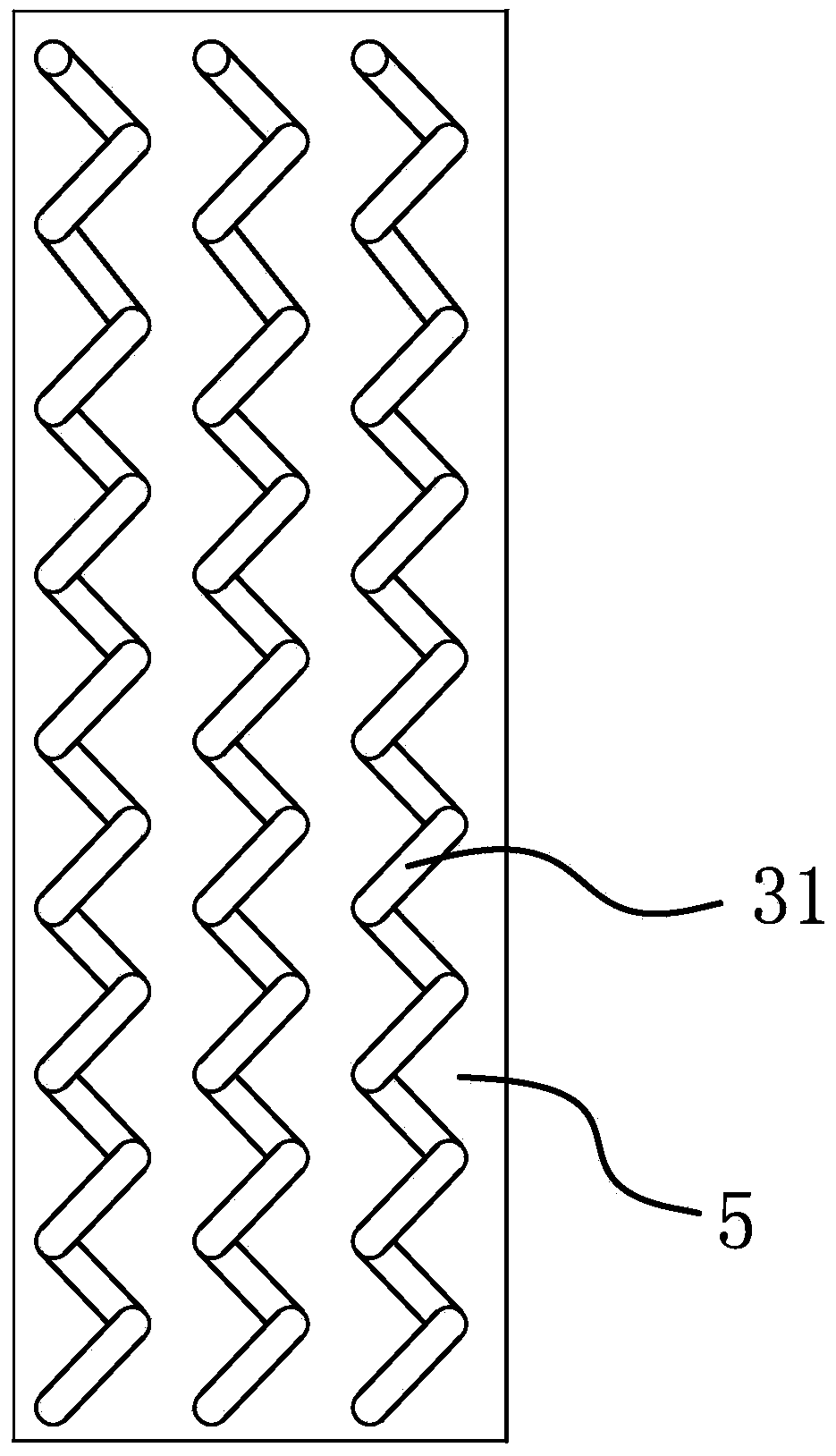

[0025] Such as figure 1 , figure 2 As shown, the flue gas heating treatment equipment includes a flue gas duct 1 , a steam pipe 2 , a drawer core 3 , a fixed core 4 , a fixed plate 5 and an inverted tapered bucket 6 .

[0026] The flue gas duct 1 includes a first air duct 11 and a fixed air duct 12. In this embodiment, the number of the fixed air ducts 12 is two, and may be one or three in actual production. Both the first air cylinder 11 and the fixed air cylinder 12 are in the shape of a cube. The width of the first air cylinder 11 and the fixed air cylinder 12 along the flue gas flow direction of the flue gas duct 1 is the same. The first air cylinder 11 and the two fixed air cylinders 12 are fixedly connected in ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com