Aviation aluminum alloy component residual stress detecting and evaluating system and method

A technology of aluminum alloy components and residual stress, which is applied in the direction of force measurement by measuring the change of magnetic properties of materials caused by applied stress, which can solve the problem that the direction of residual stress of aviation aluminum alloy components cannot be determined, and the service life of aviation aluminum alloy components can be reduced. Affect aircraft safety and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

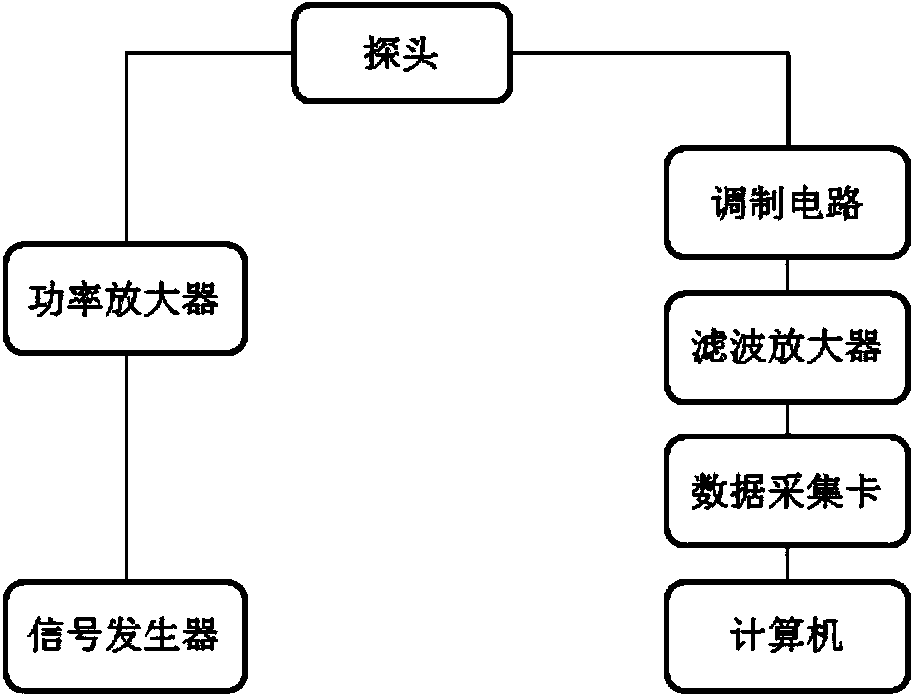

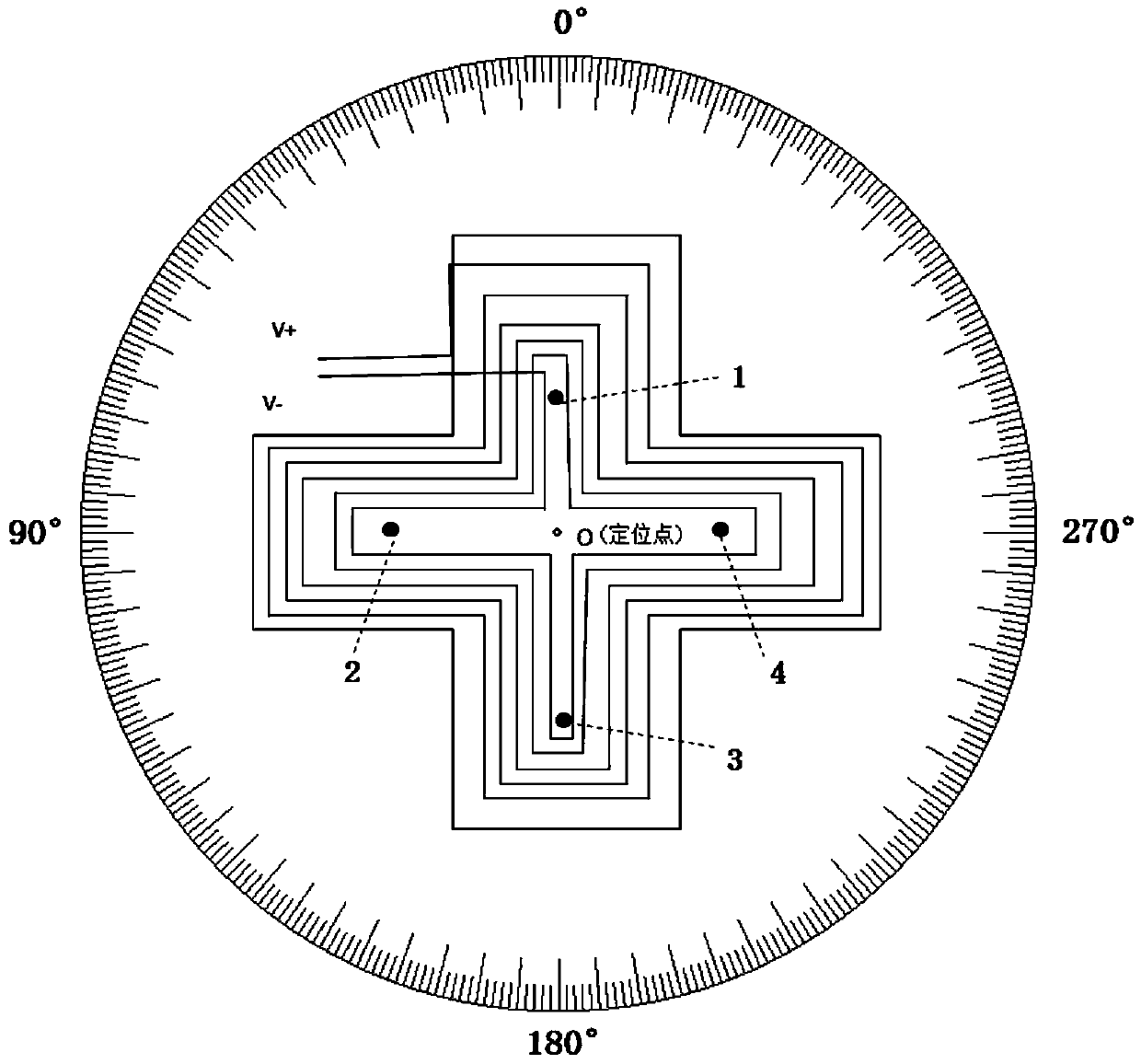

[0019] like figure 1 and figure 2 As shown, the present invention is a residual stress detection and evaluation system of aviation aluminum alloy components, including a signal generator, a power amplifier, a probe, a modulation circuit, a filter amplifier, a data acquisition card and a computer connected in sequence, and the probe includes and has The plastic base of the angle dial is bonded to a cross-shaped flexible excitation coil, and the first solid-state magnetic field sensor 1, the second solid-state magnetic field sensor 2, the third The solid-state magnetic field sensor 3 and the fourth solid-state magnetic field sensor 4, the central positioning point O of the cross-shaped flexible excitation coil coincides with the center of the circle of the plastic substrate with the angle dial, the connection of the first solid-state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com