Wellhead detection unit for drilling tool screw thread stress conditions

A detection device and thread technology, applied in the direction of force measurement, material magnetic variable, etc. by measuring the change of magnetic properties of materials caused by applied stress, can solve the problems of difficult to reach the root of the internal thread, difficult to achieve, and large wall thickness. The effect of reducing detection errors, fast detection speed and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

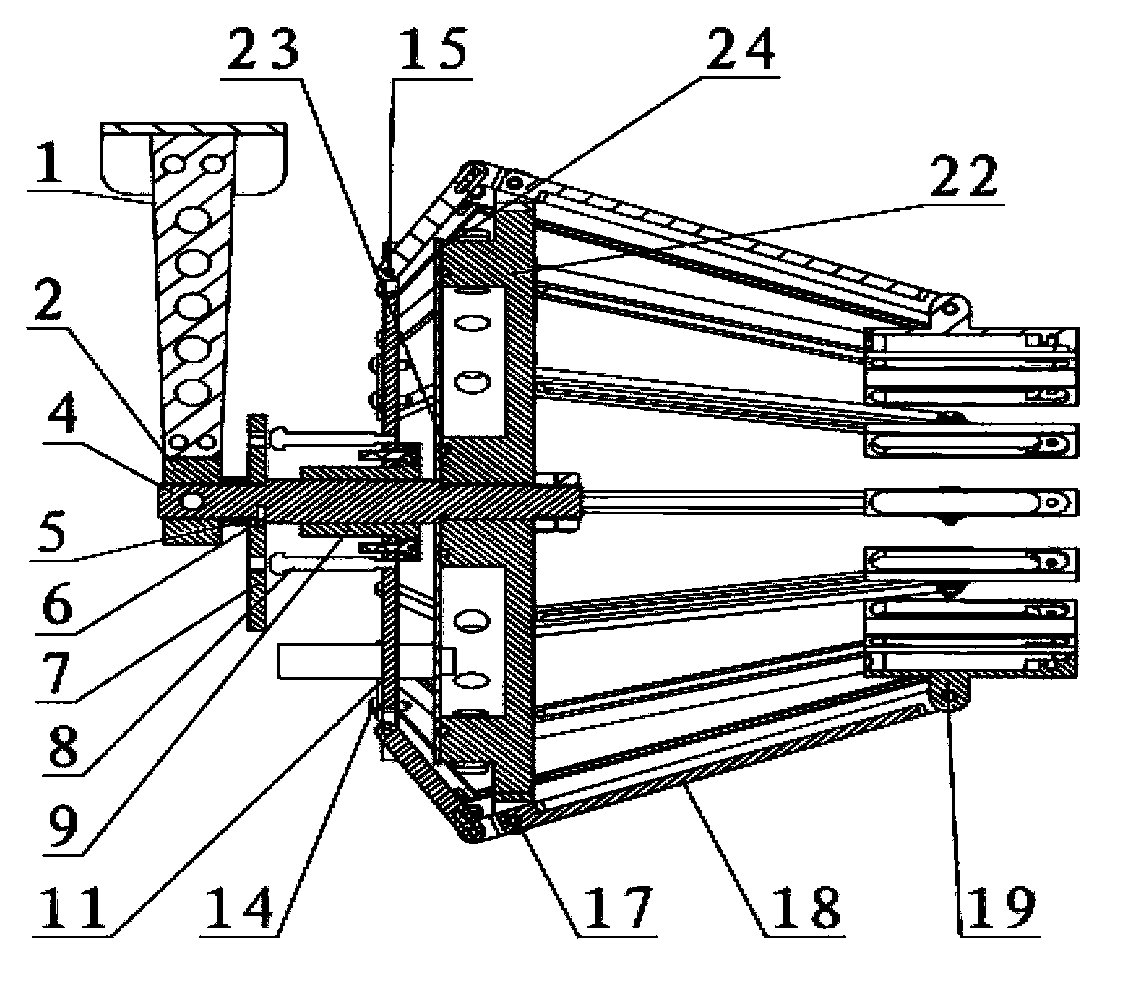

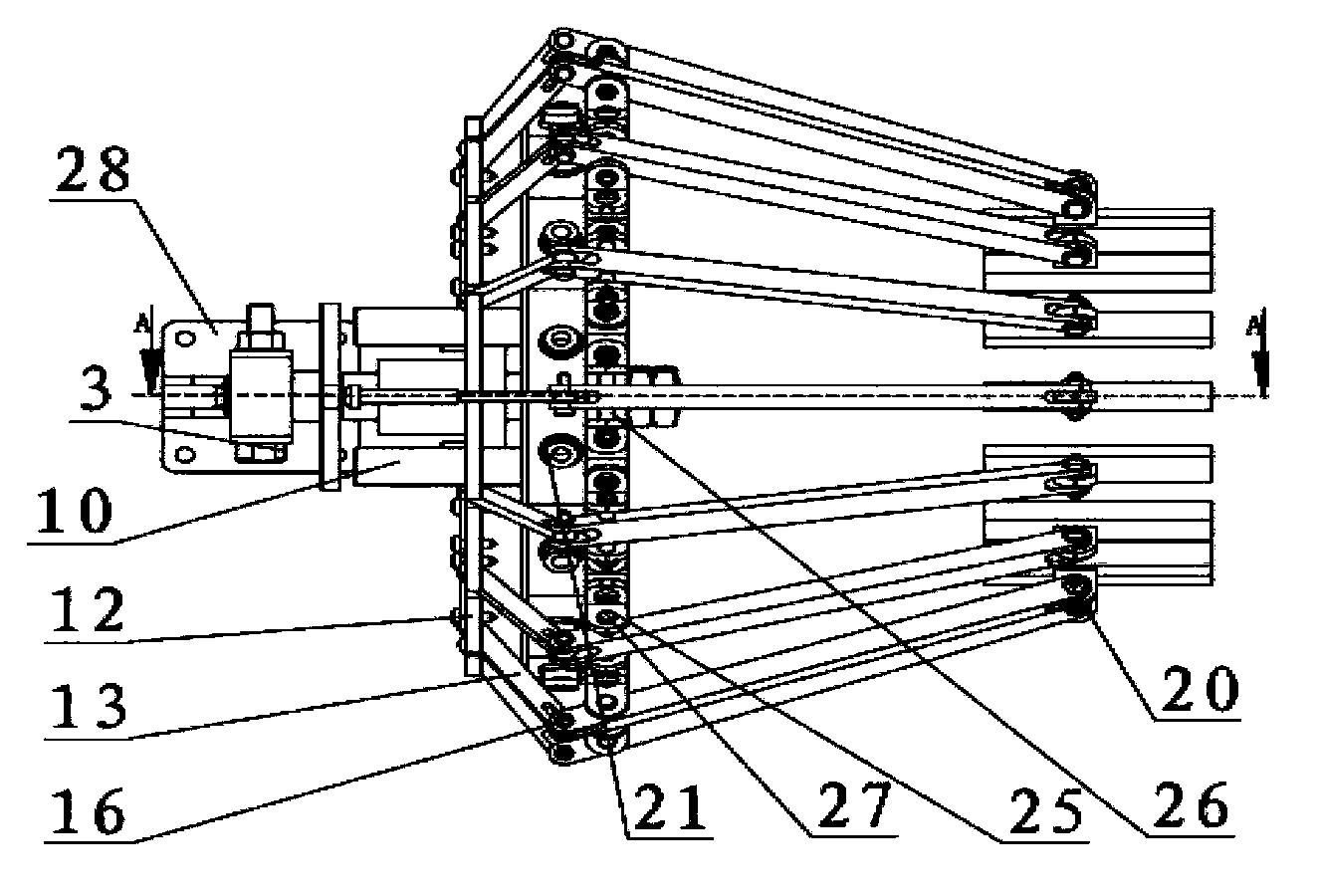

[0026] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 as shown,

[0027] A wellhead detection device for the thread stress state of drilling tools. The rib plate 1 is fixed with the conversion block 2 by screws, and the conversion block 2 and the main shaft 4 are fixed by M8 bolts 3. Insert it into the light hole of the main shaft 4, the right side of the rotating ring 7 and the shoulder of the main shaft 4 and the left side are fixed with the copper sleeve 5, the rotating ring 7 can only rotate tangentially and be fixed in the axial direction, and the positioning pin shaft 6 is limited The rotation angle of the rotating ring 7 is 45°, the threaded connection between the lower end of the bearing nail 8 and the umbrella rod disc 12 is threaded, the flange linear bearing 9 and the umbrella rod disc 12 are connected by bolts, and the bearing nail 8 faces left along the axis of the main shaft 4 The movement drives the umbrella pole disc 12 to move axially to the ...

Embodiment 2

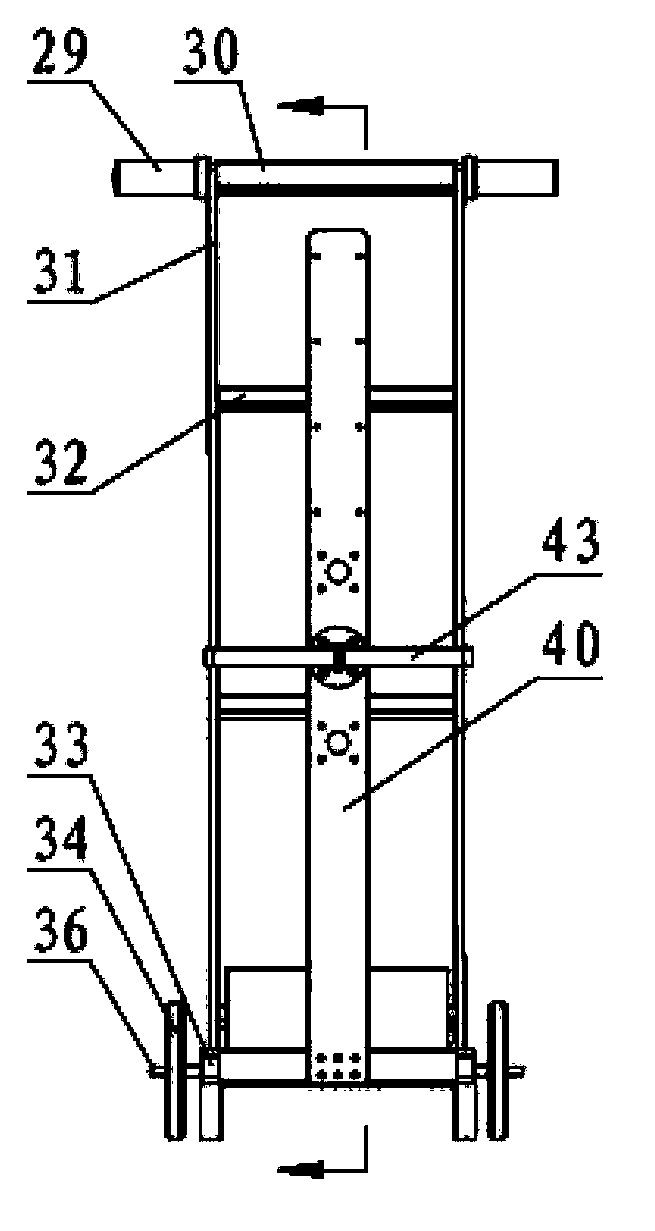

[0030] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 as shown,

[0031] A drilling tool thread stress state wellhead detection device, comprising a drilling tool joint thread detection device, a linear guide rail, a drilling tool joint outer diameter centering mechanism, a carrying trolley, a power supply, an instrument control box, including a positioning rod flange base 41, a centering Shaft 42, centering clip 43, positioning rod flange base 41 is fixed on the support plate 40, centering clip 43 is fixed on the centering shaft 42 by screws, and centering shaft 42 is inserted into the travel hole of the positioning flange base 41;

[0032] The drilling tool joint threaded wellhead detection device includes a rib plate 1, a conversion block 2, a main shaft 4, a copper sleeve 5, a positioning pin shaft 6, a rotating ring 7, a bearing nail 8, a flange linear bearing 9, a wall sealing joint 10, and a steel ring Cover sheet 11, umbrella pole disk 12, umbrella po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com