Heat efficiency calculating method for pulverized coal boiler with blending combustion of blast furnace gas

A technology for blast furnace gas and pulverized coal boilers, which is applied in calculation, special data processing applications, instruments, etc., and can solve problems such as the difficulty of accurately obtaining the amount of coal burned into the furnace and the difficulty of measuring and calculating the thermal efficiency of the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

[0058] The local atmospheric pressure in the present invention refers to the atmospheric pressure at the place where the pulverized coal boiler is located.

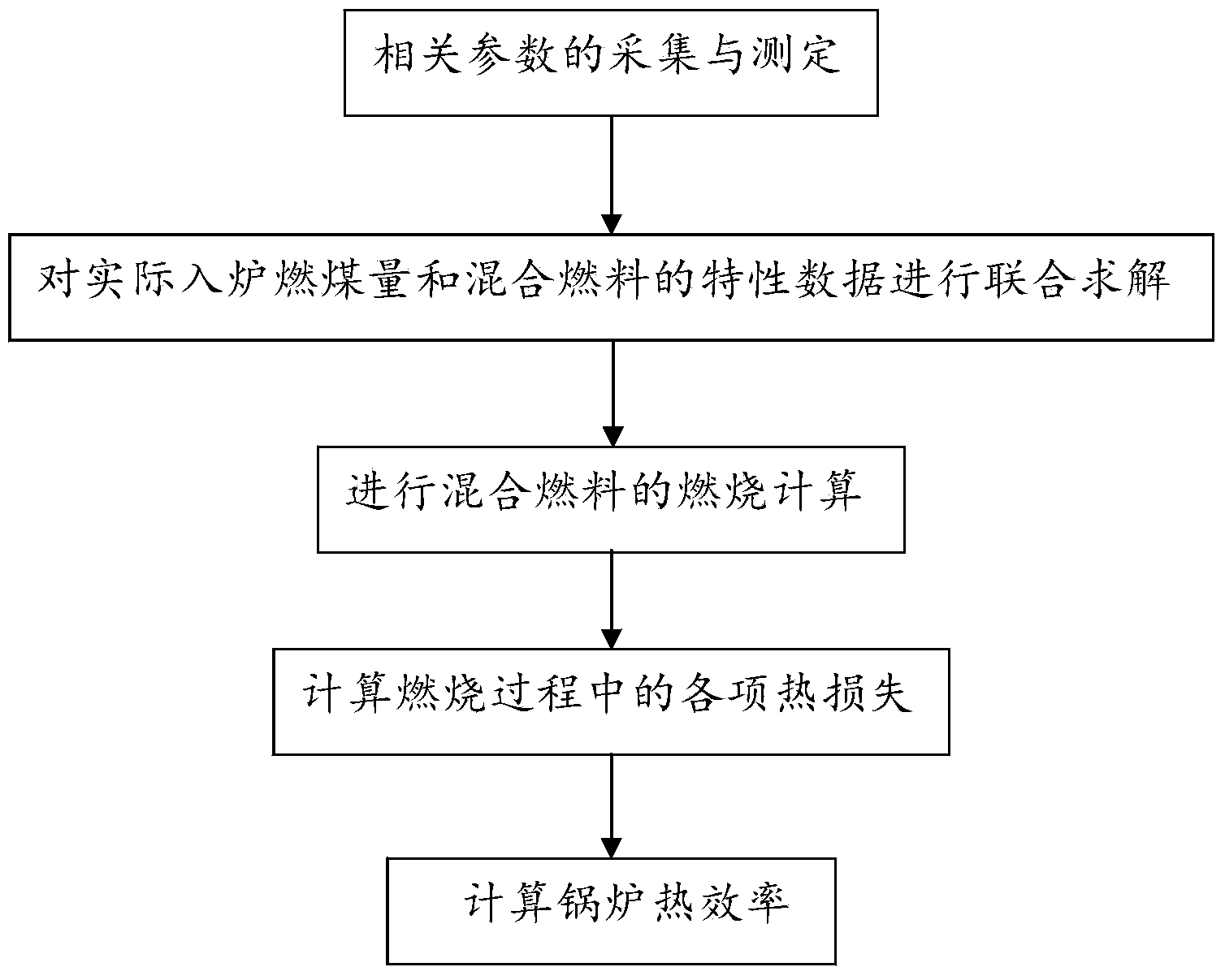

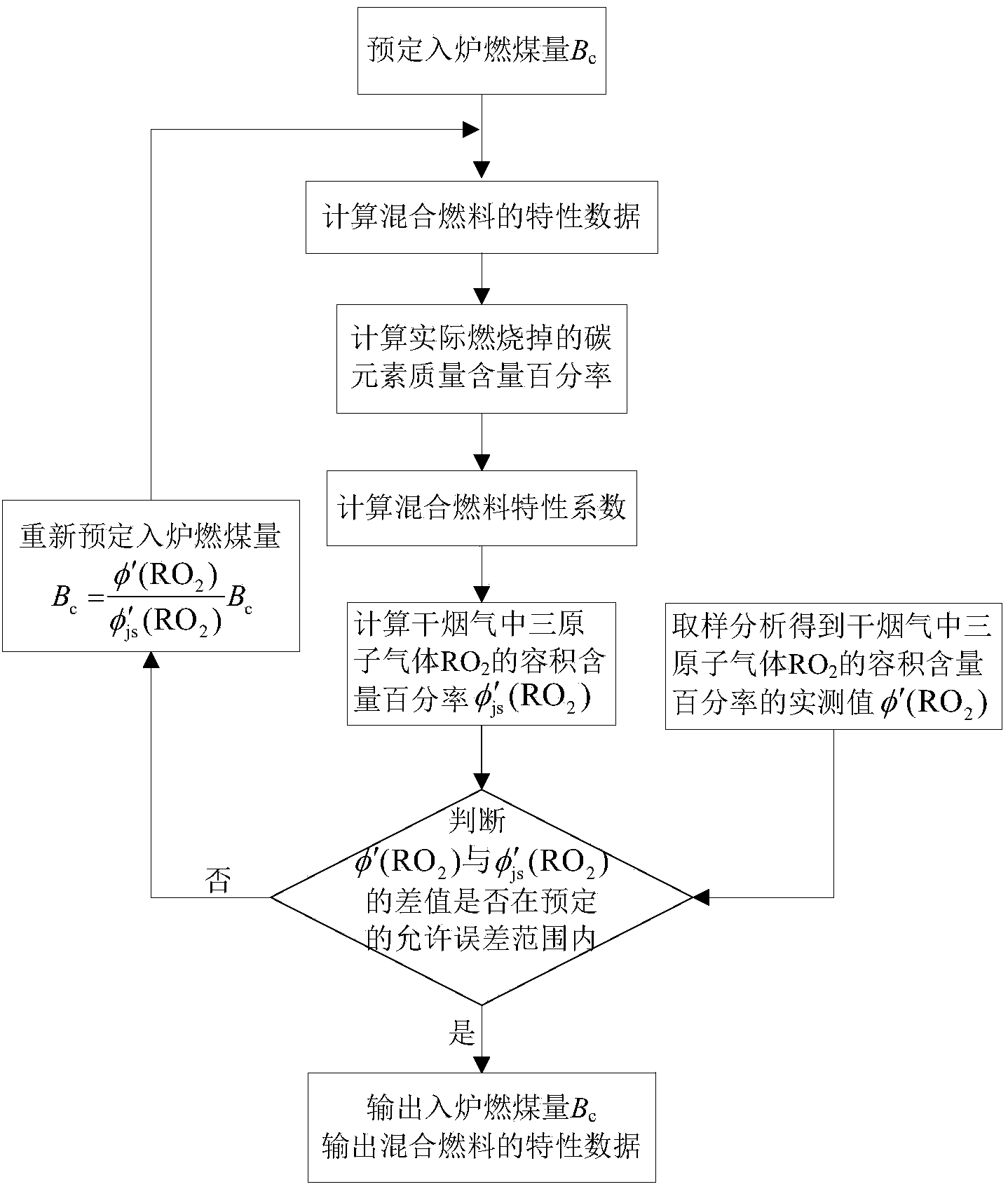

[0059] The method for measuring and calculating the thermal efficiency of the pulverized coal boiler mixed with blast furnace gas of the present invention comprises the following steps:

[0060] Step 1, collecting and measuring various input parameters, the various input parameters include characteristic data of coal combustion, characteristic data of blast furnace gas, ash parameters, dry flue gas parameters, atmospheric parameters and flow parameters:

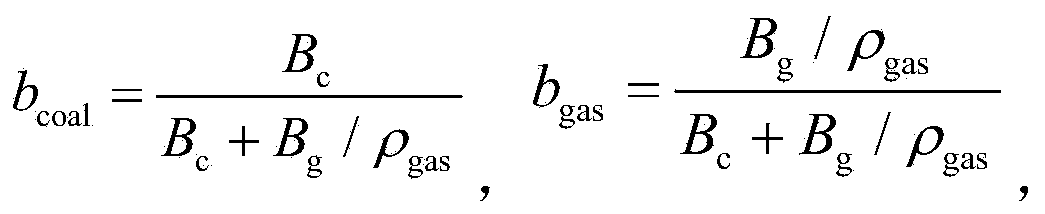

[0061] Sampling and analysis of raw coal and pulverized coal: Sampling raw coal and pulverized coal on the coal feeder and pulverized coal sampling pipe respectively, carry out laboratory analysis and calculation processing on the raw coal sample and pulverized c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com