Cartridge and multicomponent cartridge

A multi-component, barrel-walled technology, applied in the direction of distribution devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of sharp edges or sharp corners sensitive to mechanical influence, and achieve reduced wall thickness and raw materials , the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

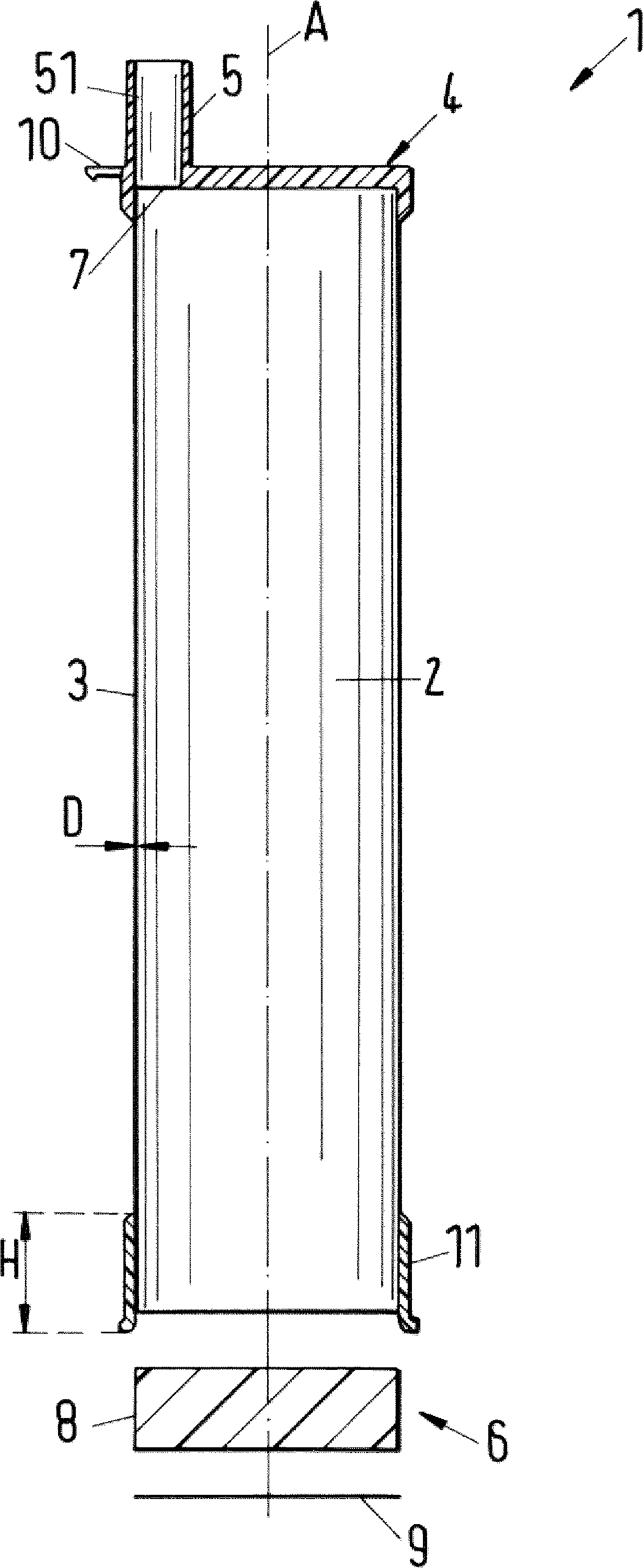

[0038] figure 1 An exemplary embodiment of a cartridge according to the invention is shown in longitudinal section, which is generally designated by the reference numeral 1 . The cartridge 1 comprises a receiving chamber 2 extending in the longitudinal direction for the medium to be discharged. The longitudinal direction is determined by the longitudinal axis denoted A of the cartridge 1 . The receiving chamber 2 is delimited by a cylinder wall 3 , a top part 4 and a bottom part 6 . The bottom part 6 comprises a piston 8 in this embodiment, which figure 1 has not yet been inserted into the receiving chamber 2, but is shown outside this receiving chamber.

[0039] The receiving chamber 2 of the cartridge 1 is configured cylindrically, that is to say the cartridge wall 3 is the peripheral side of the cylinder. The head piece 4 of the cartridge 1 has an outlet 5 , which in turn has an outlet channel 51 for the medium, through which the medium can be discharged from the receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com