Device for preparing amino acid derivatives

A technology of derivatives and amino acids is applied in the field of process equipment for preparing glutathione, which can solve the problems of large environmental pollution, low efficiency, and increase the cost of glutathione, and achieves the effect of less three wastes and avoiding dumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

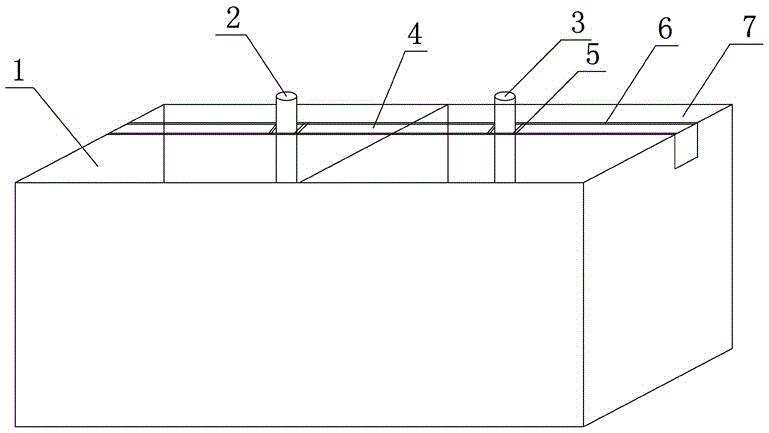

[0012] Such as figure 1 , a device for preparing amino acid derivatives, including a negative electrolytic cell 1, a positive electrolytic cell 7, a cathode rod 2, an anode rod 3, and a diaphragm; it also includes an electrode frame 4, which includes a guide rail and a moving piece 5, said There are two guide rails, and there is a distance between the two guide rails. There is a groove inside the guide rail, and the two ends of the moving piece 5 are embedded in the groove, and move between the two guide rails; the moving piece 5 has Multiple groups, the guide rails are stretched and adjusted to adjust the distance between the guide rails; the electrode frame 4 is an insulator.

[0013] In this embodiment, the cathode rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com