Tubular bag machine for filling a product

A technology for filling pipes and hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

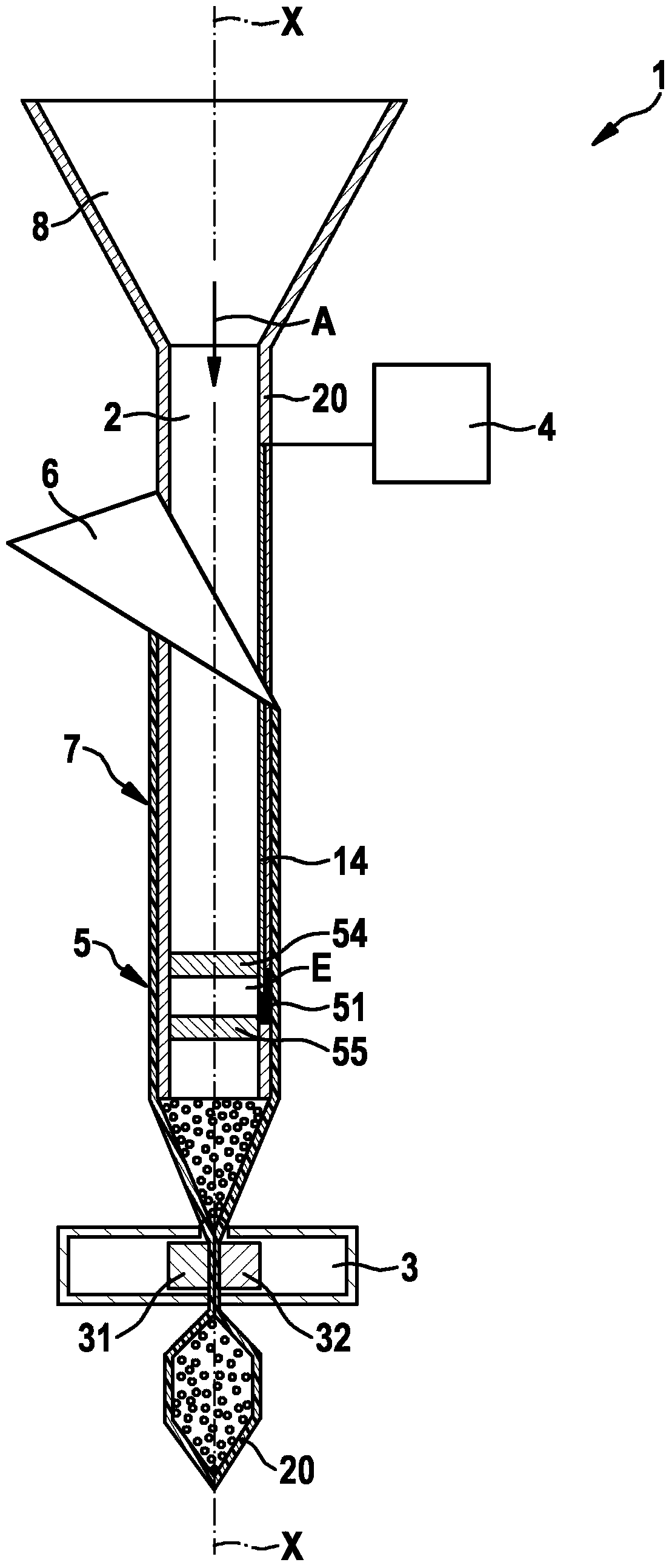

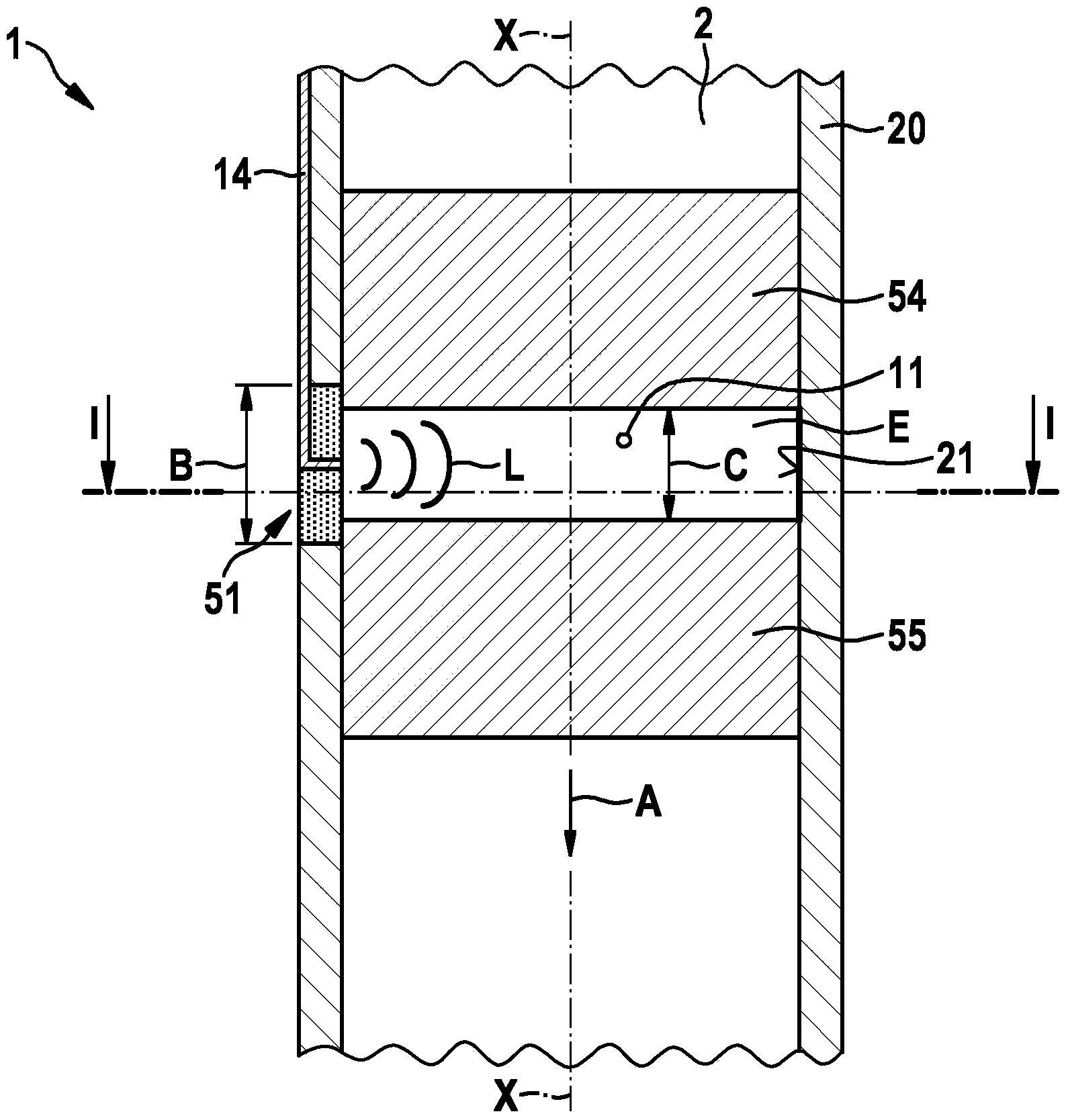

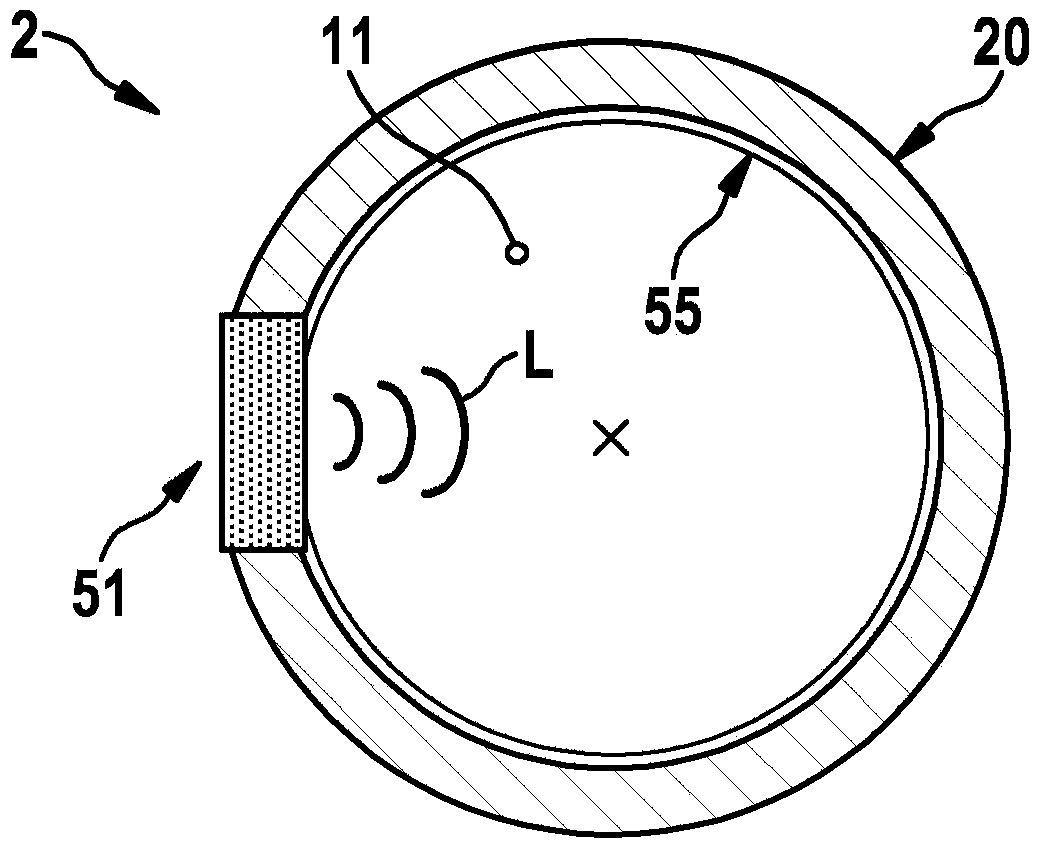

[0019] Refer below figure 1 -3 Describe in detail the hose bag machine for filling products according to a preferred embodiment.

[0020] figure 1 A schematic sectional view of a hose bag machine 1 for filling products according to a preferred embodiment of the invention is shown. The tube bag machine 1 comprises a filling funnel 8 in which the product to be filled is supplied in portions in a falling direction A to a vertical filling pipe 2 fastened thereto. Via the forming shoulder 6, the circulatingly fed packaging material is formed around the filling tube 2 into an elongated packaging material tube 7, which is longitudinally sealed by means of a longitudinal sealing seam, not shown here, by means of a longitudinal sealing unit. welding. The tube bag machine 1 also includes a transverse sealing unit 3 with first and second horizontal sealing jaws 31 , 32 , which is arranged at the end of the filling tube 2 opposite the filling funnel 8 . The horizontal sealing unit 3 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com