Reciprocating speed adaptive pulse injection device

A pulse injection and self-adaptive technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and the filtration of dispersed particles, can solve the problems of many pressure sensors, more fault factors, and poor real-time performance, so as to reduce maintenance and repair Difficulty, reducing the number of uses, and reducing the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

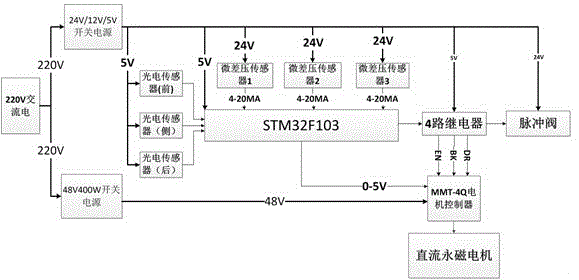

[0026] Embodiment 1: The self-adaptive pulse injection device includes: flower plate 1, left guide rail 2-1, right guide rail 2-2, horizontal blowing pipe 3, left moving platform 4-1, right moving platform 4-2, filter Bag 5, high-pressure gas storage tank 6, photoelectric induction front panel 7, temperature-resistant high-pressure air pipe 8, photoelectric induction side panel 9, electromagnetic pulse valve 10, photoelectric induction rear panel 11 and wind pressure / differential pressure sensor 26; There are a plurality of holes, and a filter bag 5 is connected to each hole, and the left guide rail 2-1 and the right guide rail 2-2 are both I-shaped steel, and are fixed on both sides of the flower plate 1; on the left guide rail 2- 1. There is a corresponding mobile platform on the right guide rail 2-2, and the mobile platform is divided into a left mobile platform 4-1 and a right mobile platform 4-2; a left mobile platform 4-1 and a right mobile platform 4-2 They are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com