Burring cutter capable of rebounding automatically

A technology for deburring and cutting tools, which is applied in the direction of tools for lathes, manufacturing tools, accessories of tool holders, etc., which can solve the problems of reduced strength, increased resilience, and insufficient resilience of deburring knives, and achieves guaranteed accuracy. , the effect of increasing the resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings.

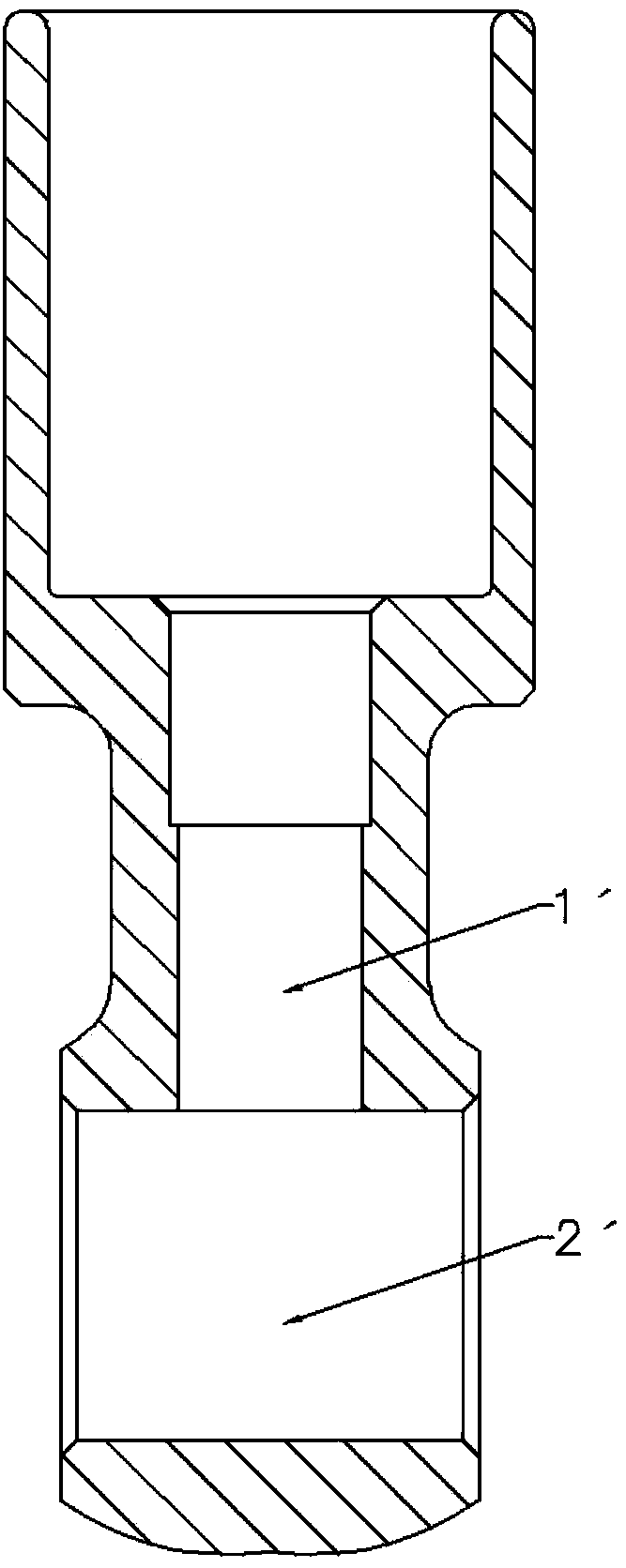

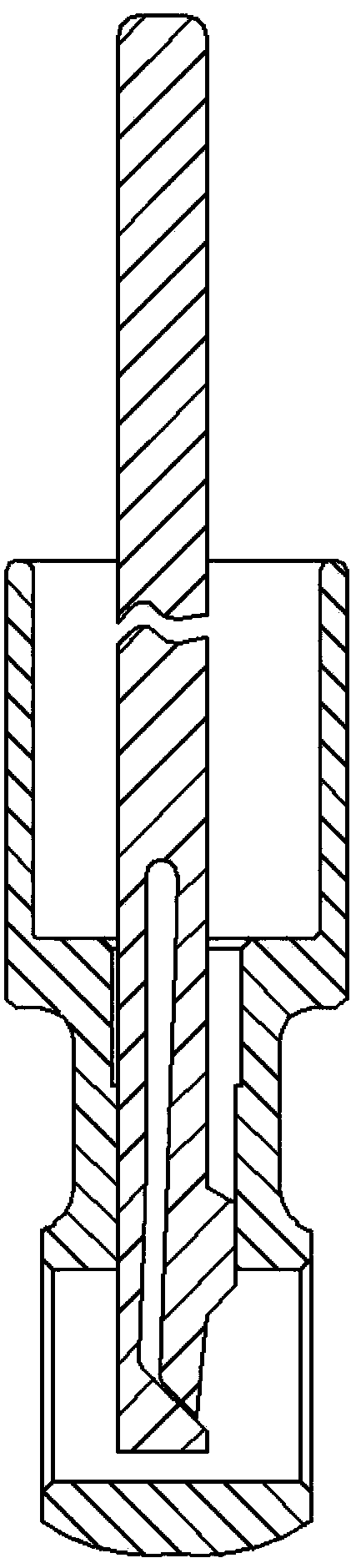

[0020] As shown in the figure, the automatic rebound deburring tool of the present invention includes the blade 1, the entire blade is an integrated structure, made of a 5-7mm (what material), to ensure that the blade has sufficient hardness At the same time, it has a certain degree of toughness.

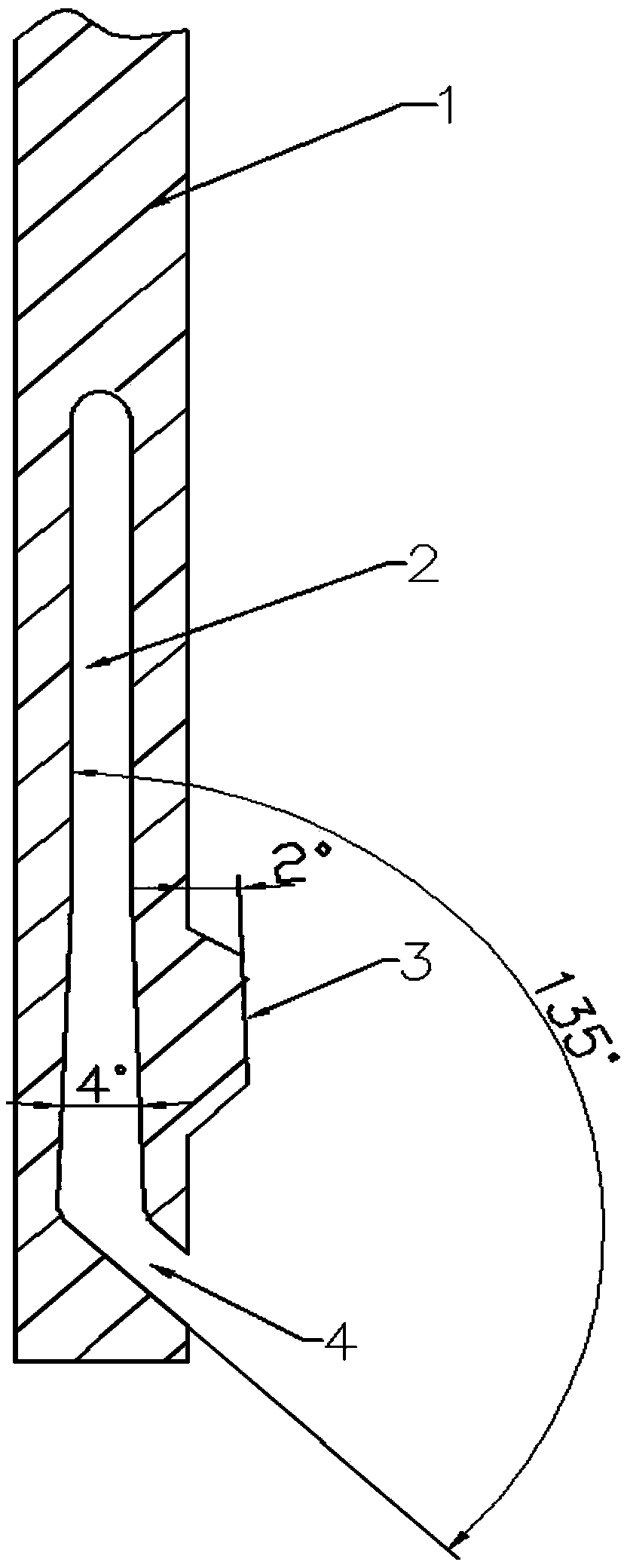

[0021] A vertical bar-shaped hole 2 perpendicular to the blade 1 is opened in the middle of the lower part of the blade 1, and a side wall of the lower part of the vertical bar-shaped hole 2 is formed with a cutting edge 3 protruding from the side wall. The blade 1 below the vertical strip hole 2 is also provided with an oblique strip hole 4 that intersects the vertical strip hole 2 at an angle of 130-140°. The bottom wall of the oblique strip hole 4 extends to the side wall of the blade 1 below the cutting edge 3, that is to say, the bottom of the oblique strip hole 4 is open, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com