Platen polishing device of vacuum drying machine

A vacuum dryer and polishing device technology, which is applied in the field of polishing machines, can solve problems such as potential safety hazards, low efficiency, and difficult work, and achieve the effects of eliminating wear, reducing labor intensity, and improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

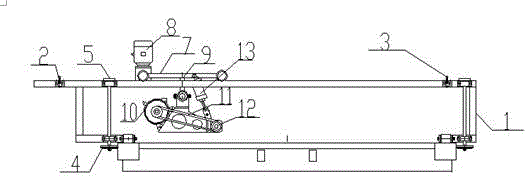

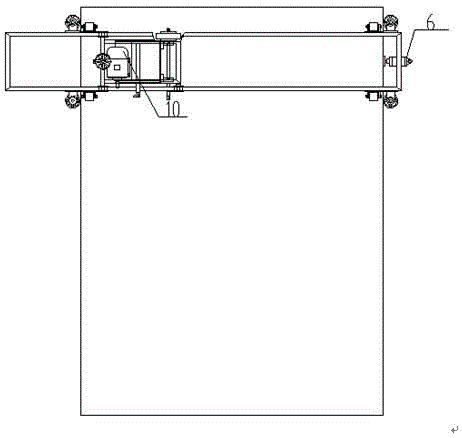

[0021] like figure 1 and figure 2 The vacuum dryer platen polishing device shown is used for grinding and polishing of the platen. The short side direction of the platen is the X-axis direction, and the long side direction is the Y-axis direction. Its innovative point is that it includes a movable support 1 , the movable support 1 straddles the top of the table, and the movable support 1 can be driven by the Y-axis driving mechanism to move along the long side of the table in the guide assembly A.

[0022] The table polishing device of the vacuum dryer also has a grinding device for polishing the surface of the table. The grinding device is installed on the movable support 1 and can be driven by the X-axis driving mechanism to reciprocate along the width direction of the table.

[0023] The platen polishing device of the vacuum dryer also has a locking mechanism that automatically locks the movable support 1 on the platen. The locking mechanism is a locking cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com