Electrical system of polycrystalline silicon rod reduction furnace and its starting method

A technology of polycrystalline silicon rods and electrical systems, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as equipment damage, and achieve the effect of eliminating potential risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

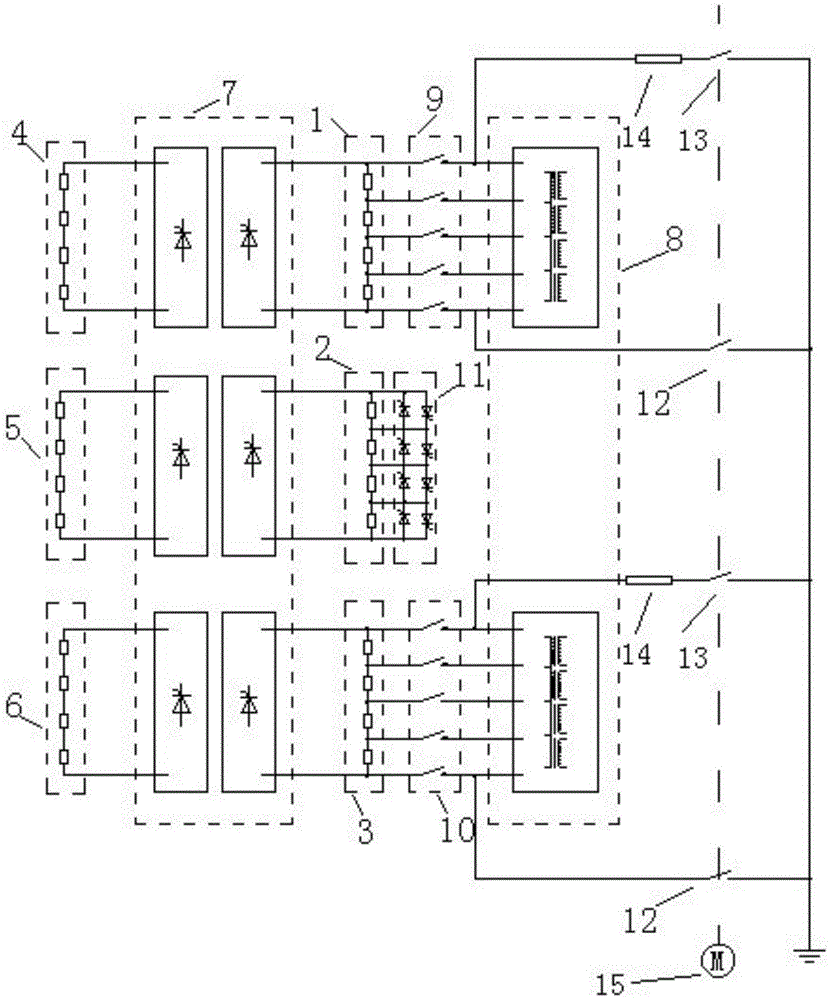

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0024] refer to figure 1 , polysilicon rod reduction furnace electrical system, including:

[0025] 24 pairs of polysilicon rods arranged in three circles, among which 4 pairs of polysilicon rods 2 are distributed in the inner ring, 8 pairs of polysilicon rods 1, 3 are distributed in the middle ring, 12 pairs of polysilicon rods 4, 5, 6 are distributed in the outer ring,

[0026] The above 24 pairs of polysilicon rods are all connected to the power supply of the power regulating cabinet, among which 8 pairs of polysilicon rods 1 and 3 are connected to the high-voltage starting power supply 8 through the isolation switch 9 and 10 in the middle circle, and 4 pairs of polysilicon rods 2 are connected to the inner circle. There are 4 groups of thyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com