Impact-resistant chip resistor and manufacturing method of chip resistor

A technology of chip resistance and impact resistance, which is applied in the direction of resistance manufacturing, resistors, resistor parts, etc., can solve the problems of high manufacturing cost of chip resistors, affecting the normal operation of circuit boards, and poor high temperature resistance, etc., to achieve good Chemical stability, good oxidation resistance, effects of improving corrosion resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings, and the preferred embodiments described herein are intended to illustrate and explain the present invention, and are not intended to limit the invention.

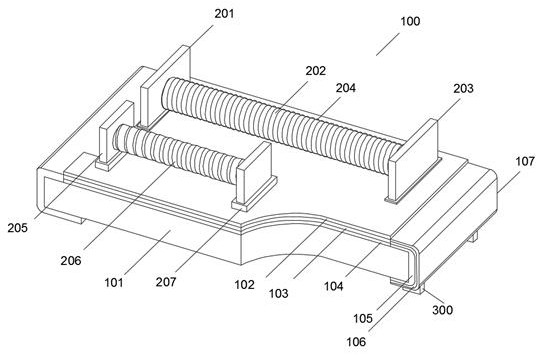

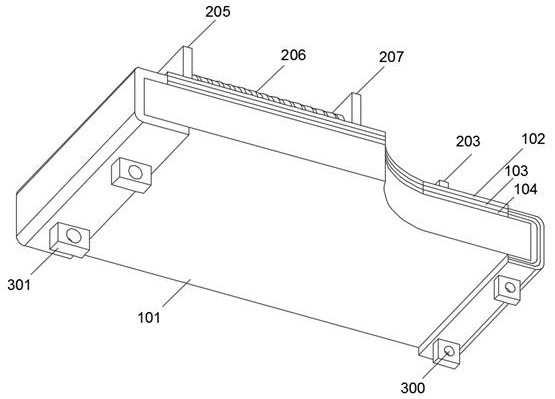

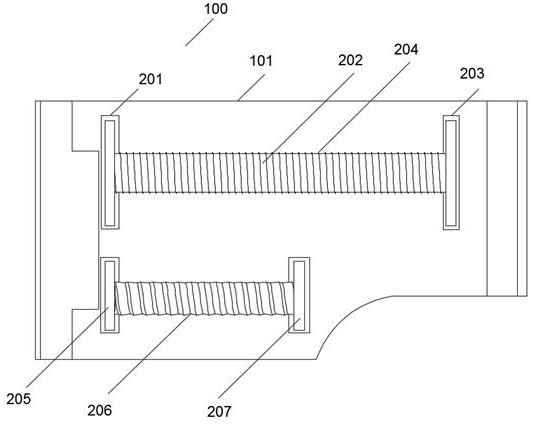

[0035] Refer to the attachment Figure 1-8 In order to achieve the above object, the present invention provides a method of improving wafer resistor and a wafer resistor, including a resistor body 100, a resistor body 100. Also included, the substrate 101 is mounted at the bottom, the top of the substrate 101 is fixedly connected to the impedance element 104, and the base layer sealing layer 103 is mounted on top of the impedance element 104. The top of the base layer sealing layer 103 is fixedly connected to the second layer sealing layer 102, and the substrate 101 side is installed The end face 105, the outer end surface 105 is attached to the outer end surface 106, and the outer end surface 106 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com