Patents

Literature

59results about How to "Reduce the possibility of breakdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

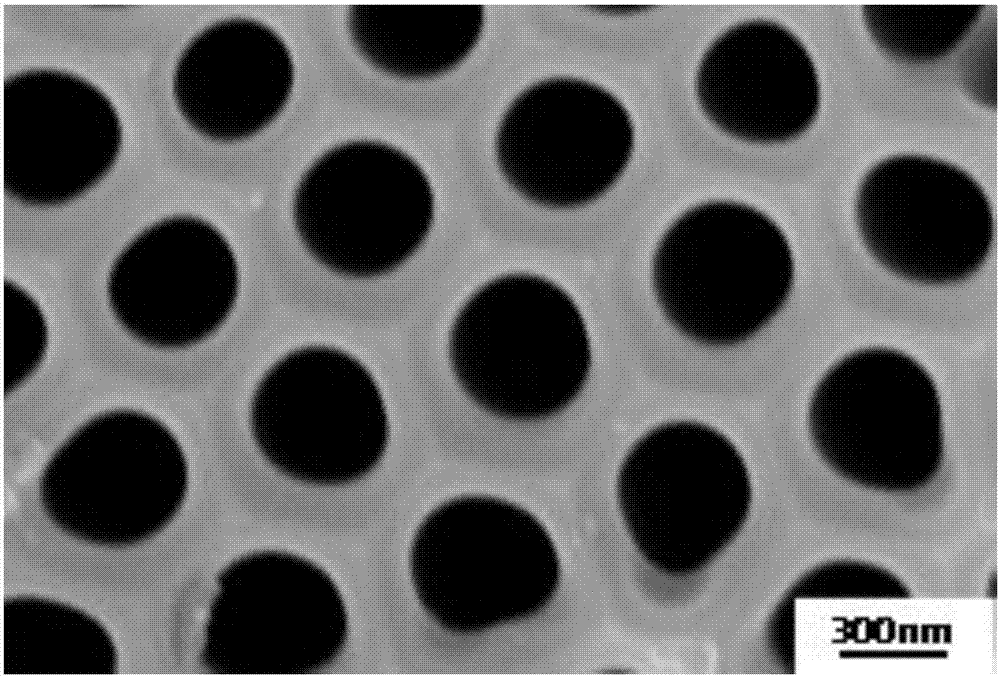

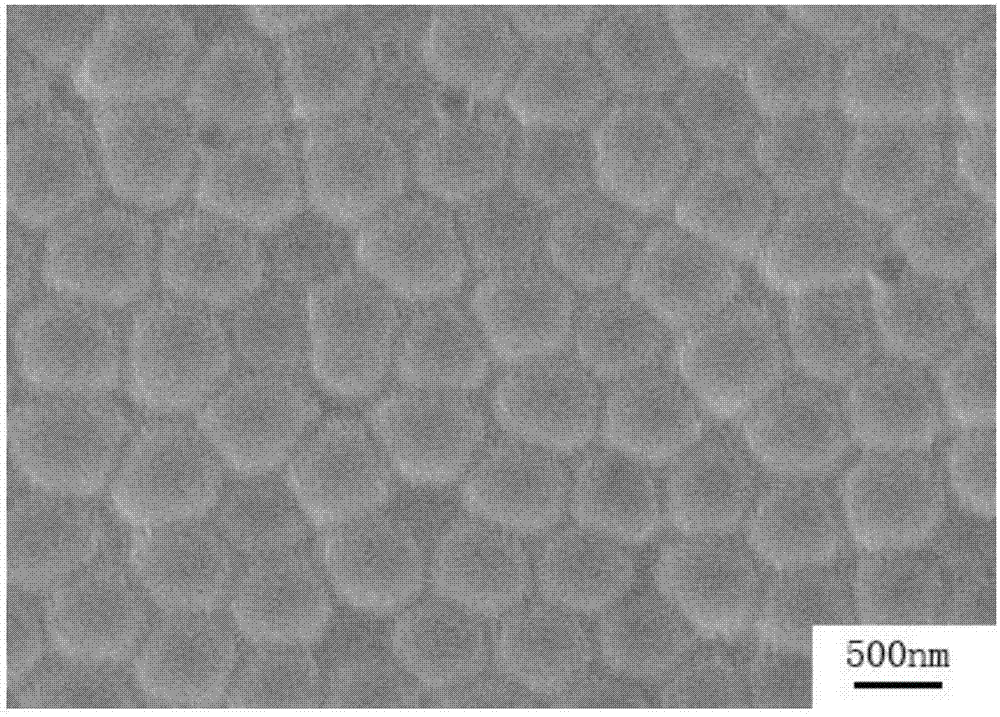

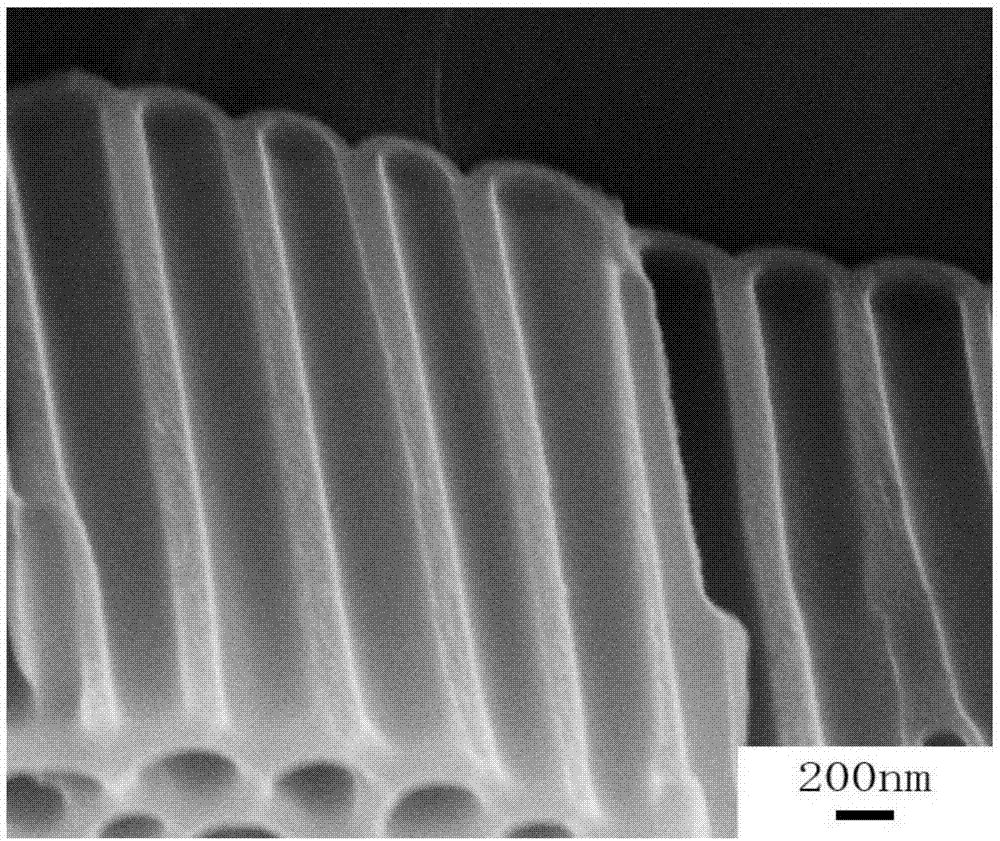

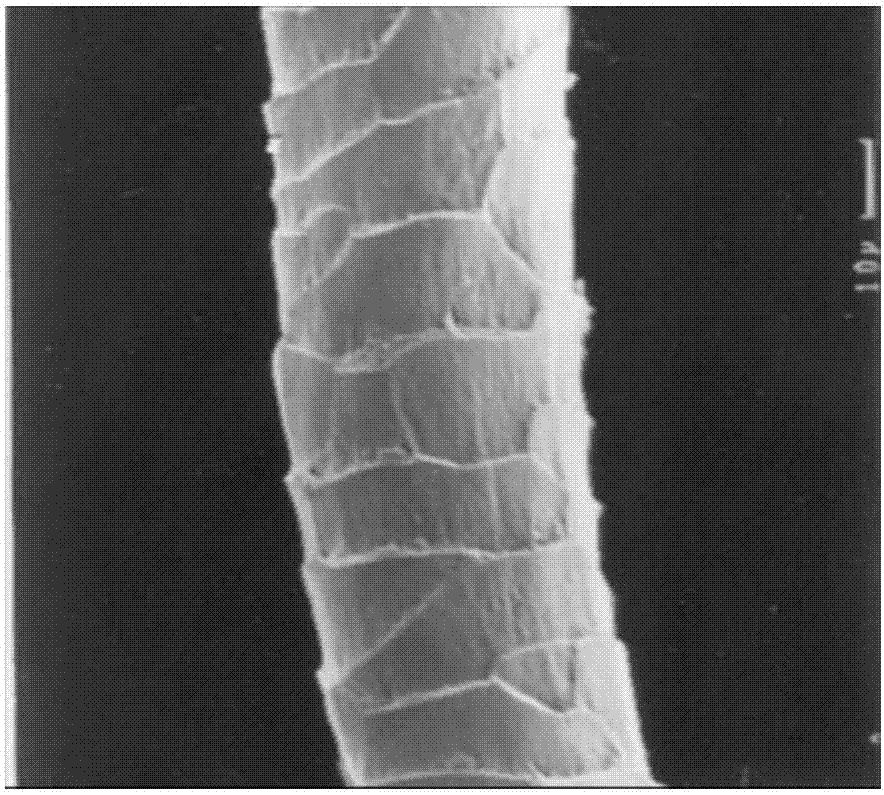

Method for obtaining large-hole-diameter double-through-hole AAO membrane

The invention discloses a method for obtaining a large-hole-diameter double-through-hole AAO membrane. The method comprises the following steps that 1, aluminum foil is pretreated, and thus aluminum foil with the surface being as smooth and flat as a mirror is obtained; 2, a large-hole-diameter single-through-hole AAO membrane with an aluminum base and a blocking layer is prepared through a secondary anodic oxidation method, wherein an anodic oxidation electrolyte is a mixed solution of phosphoric acid (with the content being 0.05 M-0.2 M) and sodium oxalate (with the content being 0.01 M-0.03 M); and 3, the aluminum base and the blocking layer of the large-hole-diameter single-through-hole AAO membrane are removed through a corrosion stripping method, wherein aluminum base corrosive liquid is a mixed solution of copper chloride (with the content being 0.1 M-0.15 M) and ferric chloride (with the content being 0.15 M-0.18 M). The method has the advantage that the double-through-hole AAO membrane which is large in hole diameter, orderly in hole arrangement, large in area and good in integrality is obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

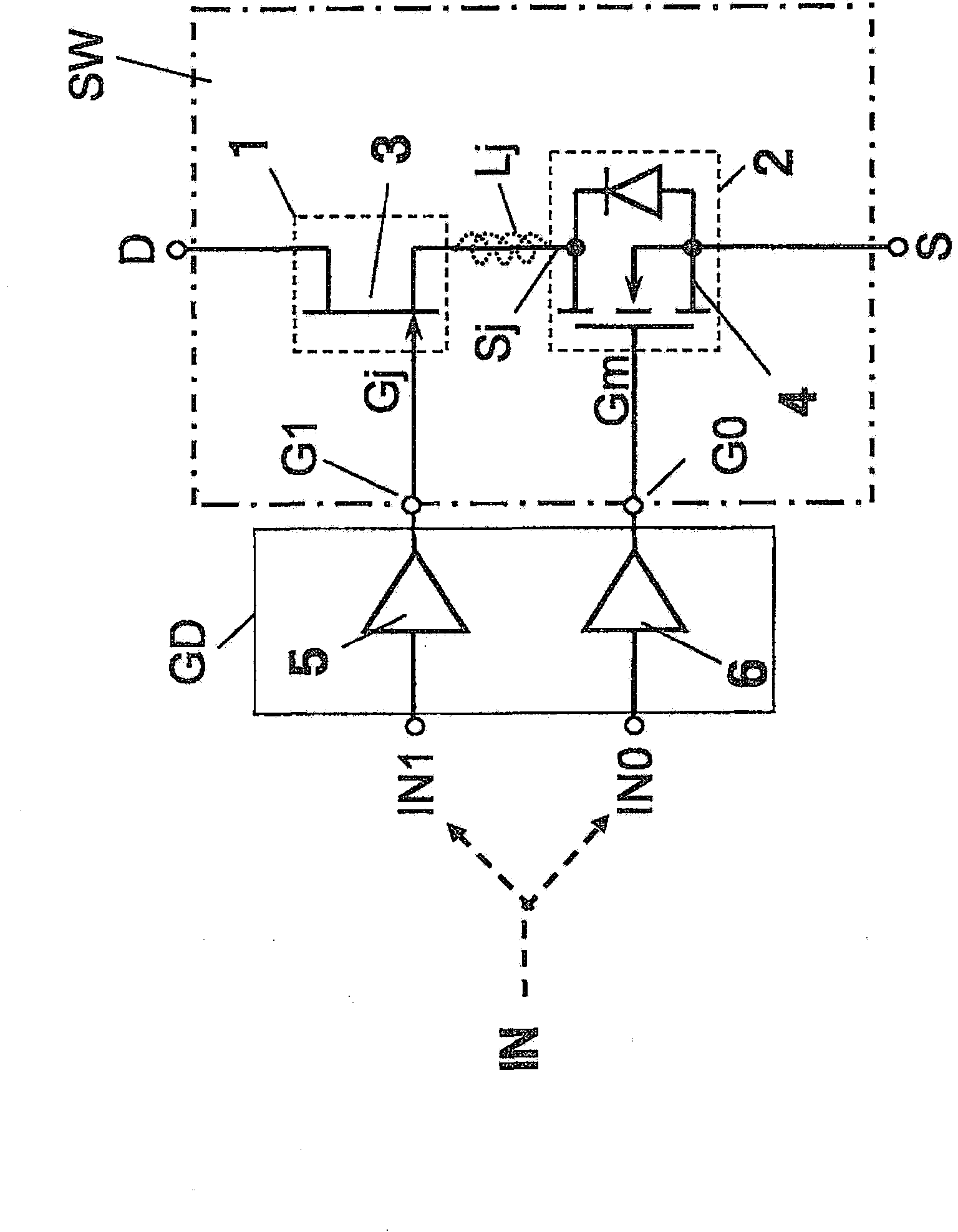

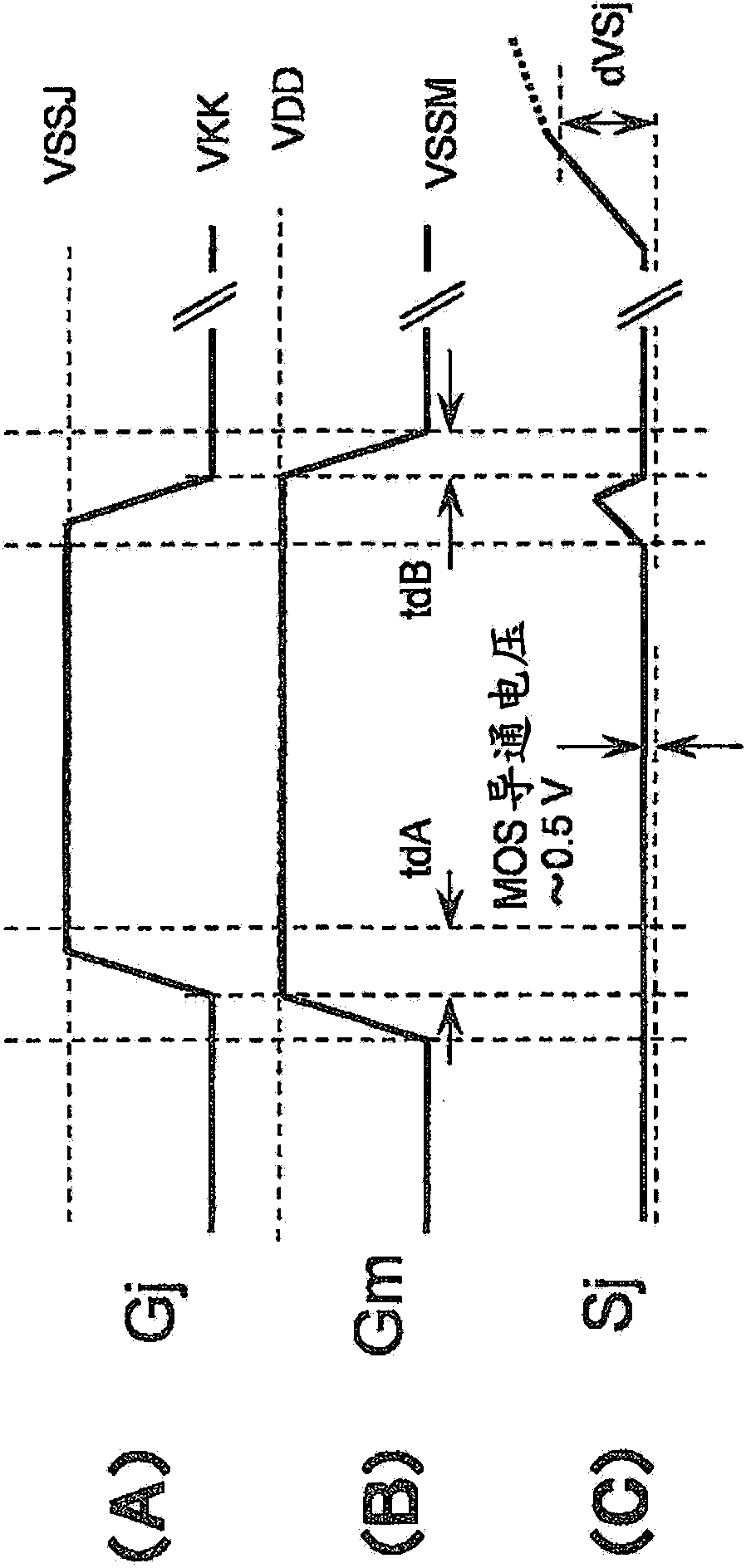

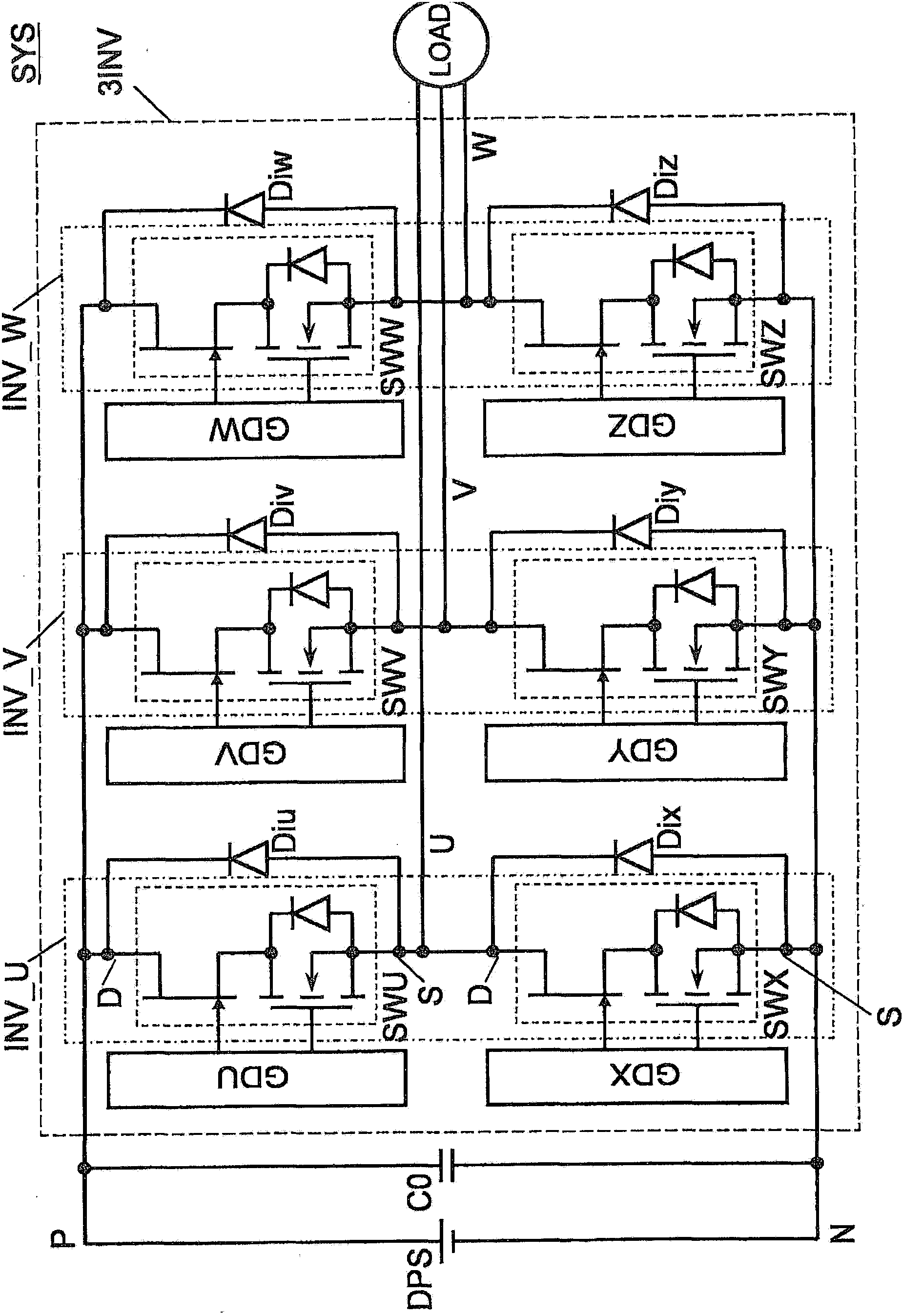

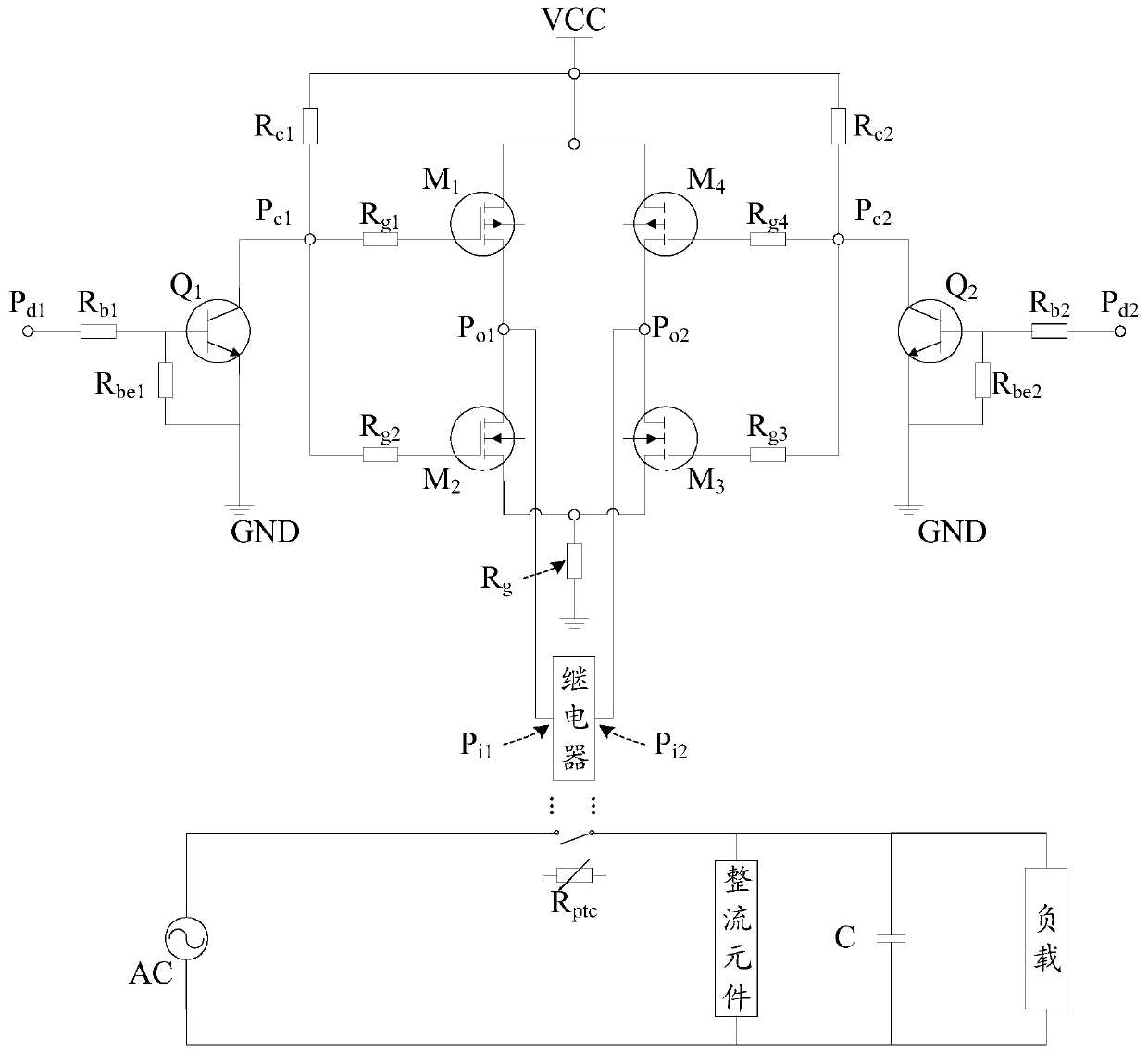

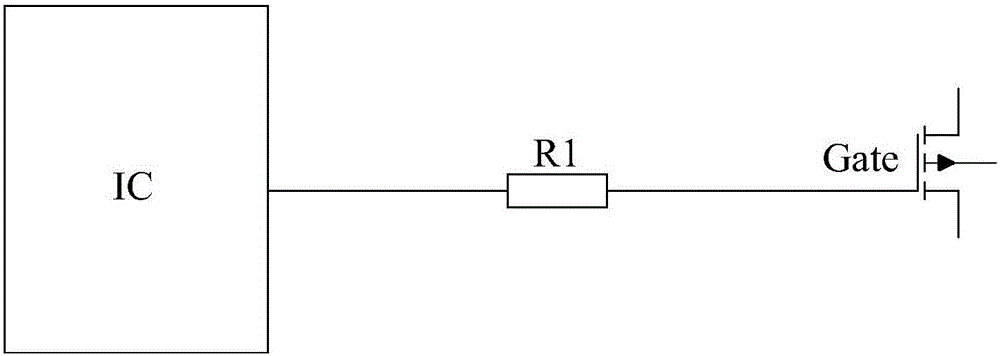

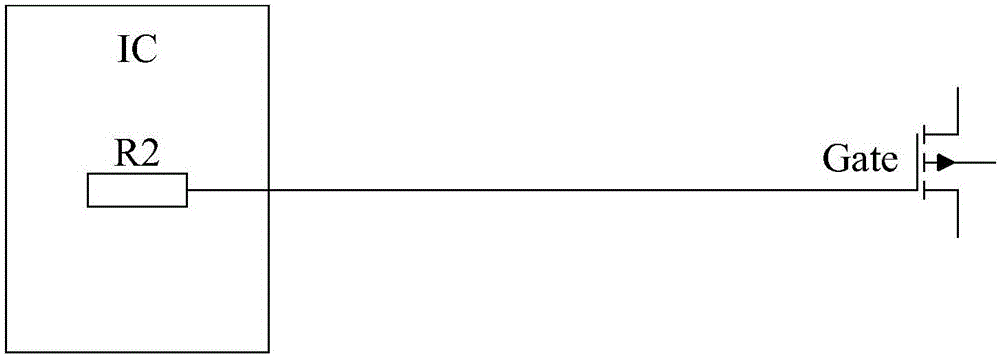

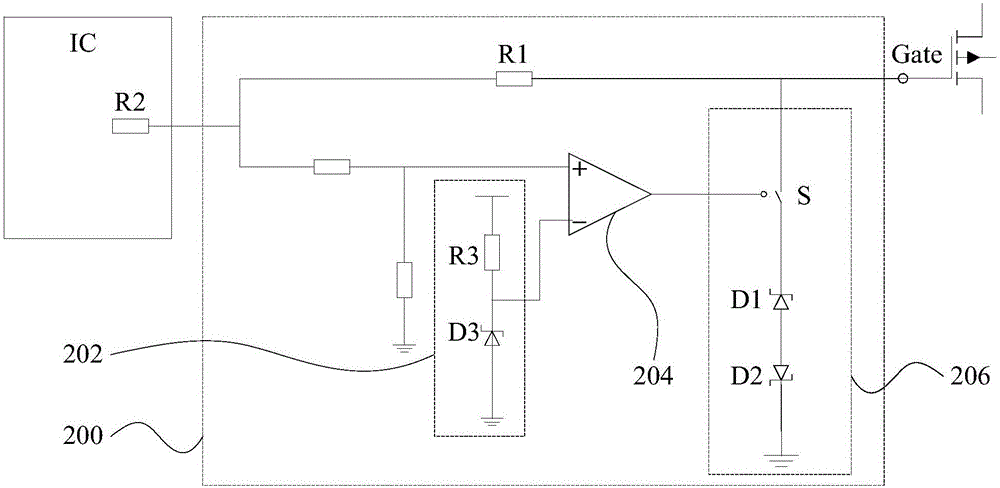

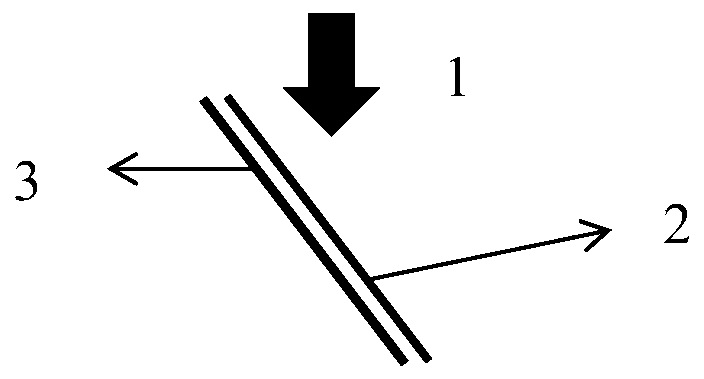

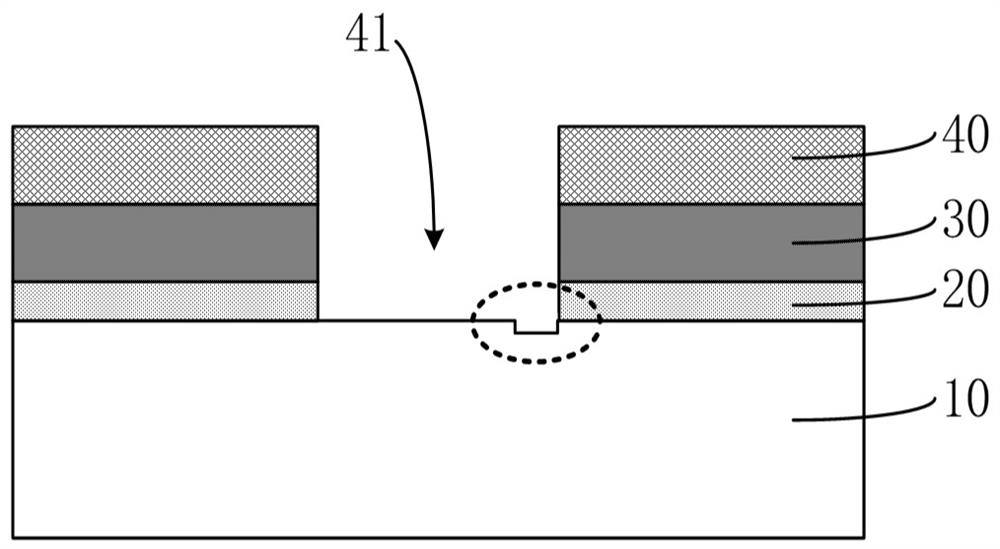

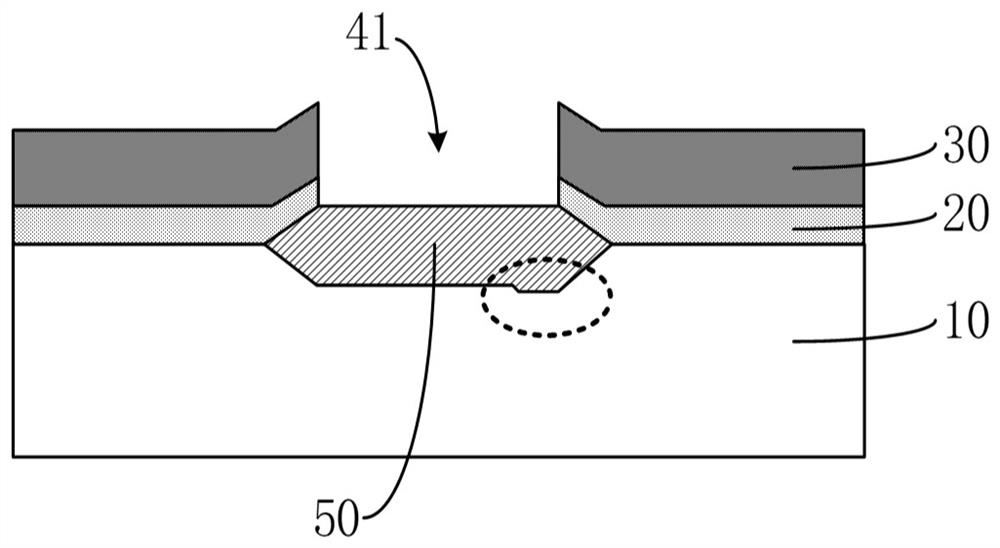

Semiconductor device and system using same

ActiveCN103516338AReduce the possibility of breakdownTransistorAC motor controlPower semiconductor deviceMOSFET

The invention provides a semiconductor device and a system using the same. The semiconductor device is configured with a normally-on SiCJFET and a normally-off Si-type MOSFET. The normally-on SiCJFET and the normally-off Si-type MOSFET are coupled in cascade and configure a switching circuit. According to one input signal, the normally-on SiCJFET and the normally-off Si-type MOSFET are controlled so as to have a period in which both transistors are set in an OFF state. According to the invention, the semiconductor device configured with the normally-on JFET and the normally-off MOSFET which are coupled in cascade can be prevented from breakdown due to mis-conduction and the like.

Owner:RENESAS ELECTRONICS CORP

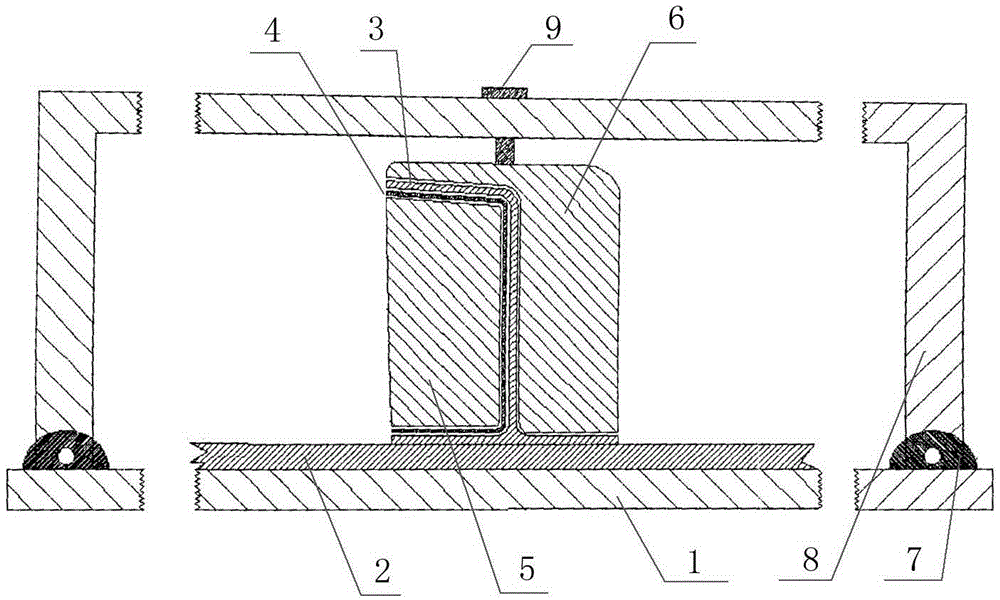

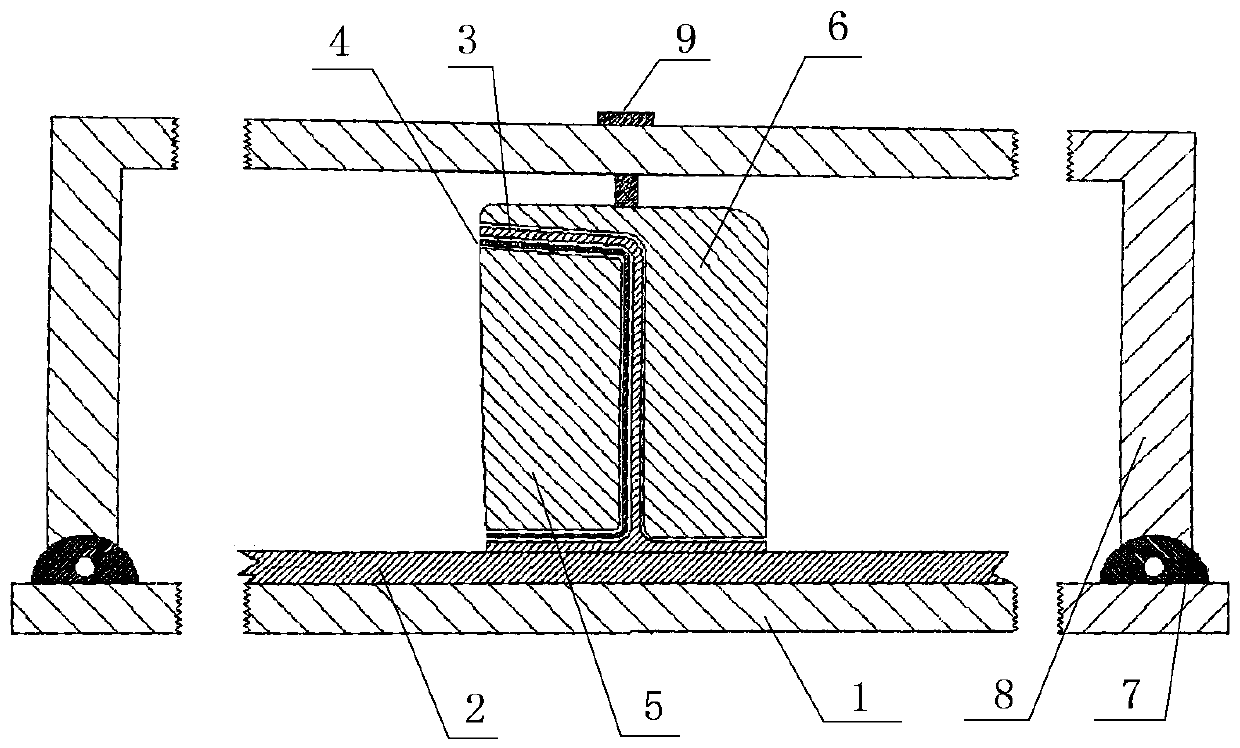

Composite material J type longitudinal wall positioning integral forming tool and forming method thereof

The invention relates to a composite material J type longitudinal wall positioning integral forming tool. A foundation coating is arranged on a coating forming tool. A J type longitudinal wall is arranged in the designated position on the upper surface of the foundation coating. An inner longitudinal wall forming tool is arranged on the inner surface of the J type longitudinal wall through a rubber compensation layer, and the inner form of the J type longitudinal wall is completely filled with the inner longitudinal wall forming tool. The outer surface of the J type longitudinal wall is coated with an outer longitudinal wall forming tool. A cuboid structure without a cavity is formed through the outer longitudinal wall forming tool, the inner longitudinal wall forming tool and the J type longitudinal wall. A positioning beam is connected with the coating forming tool through positioning lug pieces. The positioning beam stretches across the outer longitudinal wall forming tool. The top of the positioning beam is connected with the upper surface of the outer longitudinal wall forming tool through a fixing member. Specific to the structural characteristics of a carbon fiber composite material J type wall, the problems of excursion of the longitudinal wall axis size, rib-line size and longitudinal wall shape in the manufacturing process of the J type wall are solved through the optimal design of an existing tool structure.

Owner:SHENYANG AIRCRAFT CORP

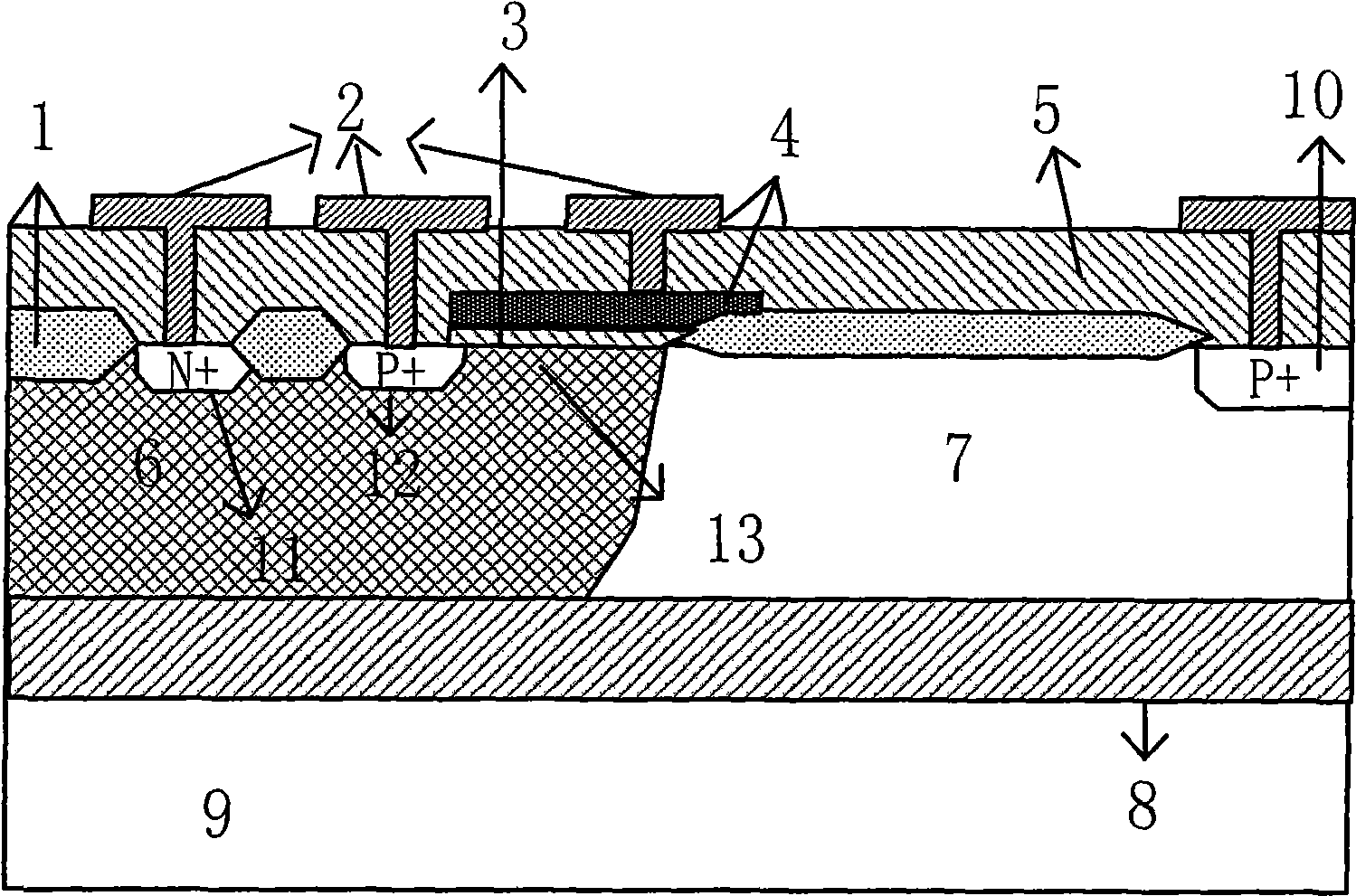

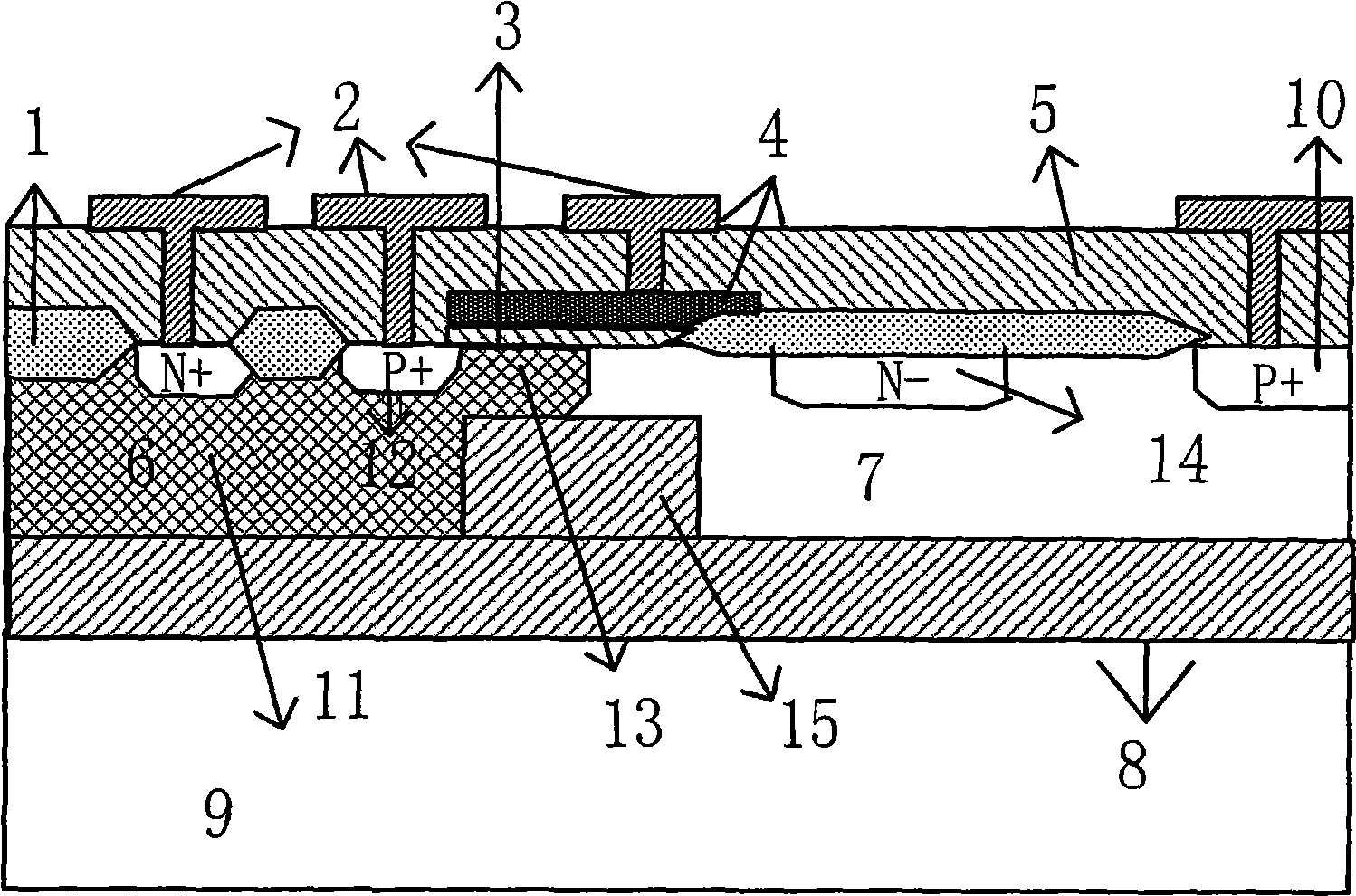

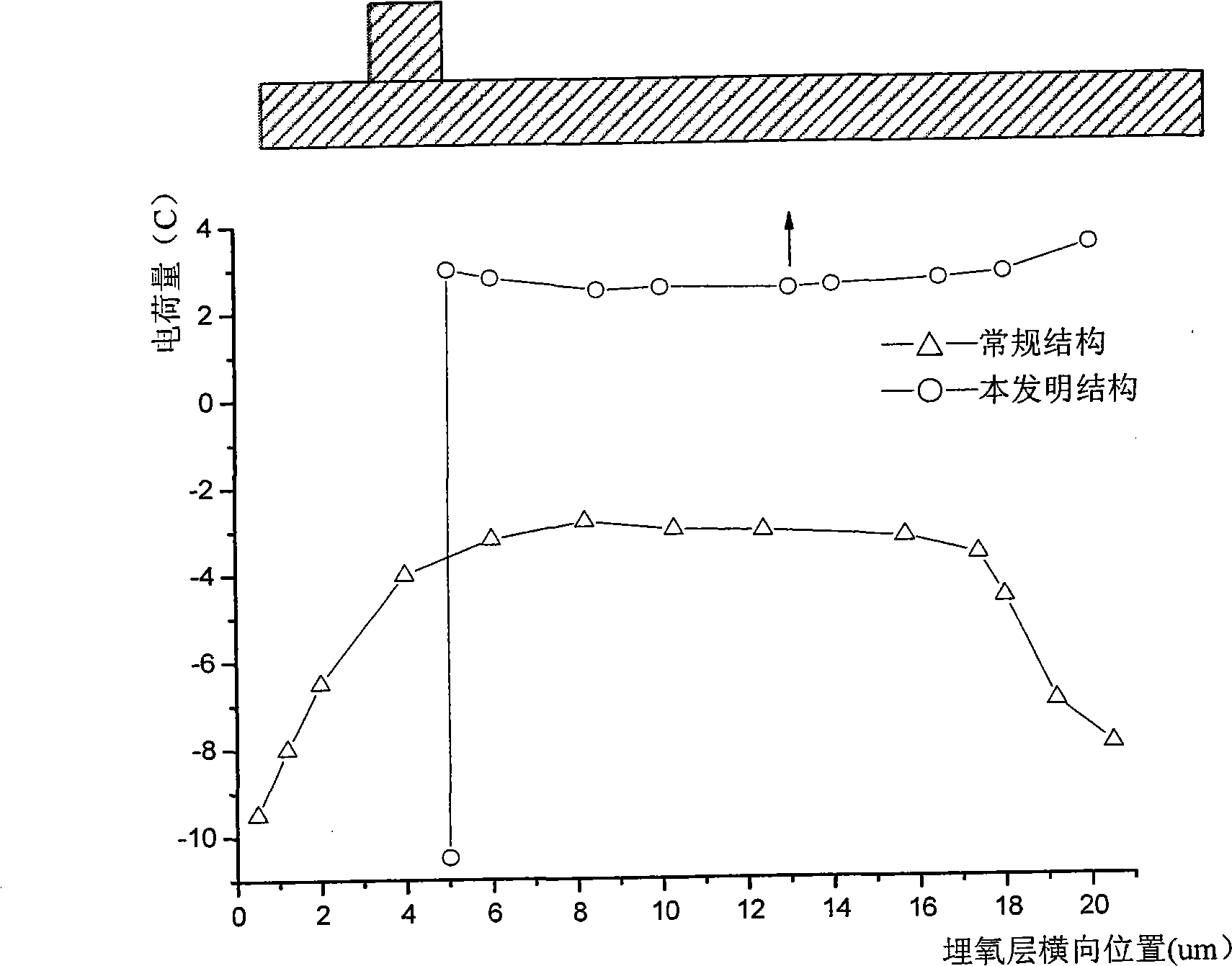

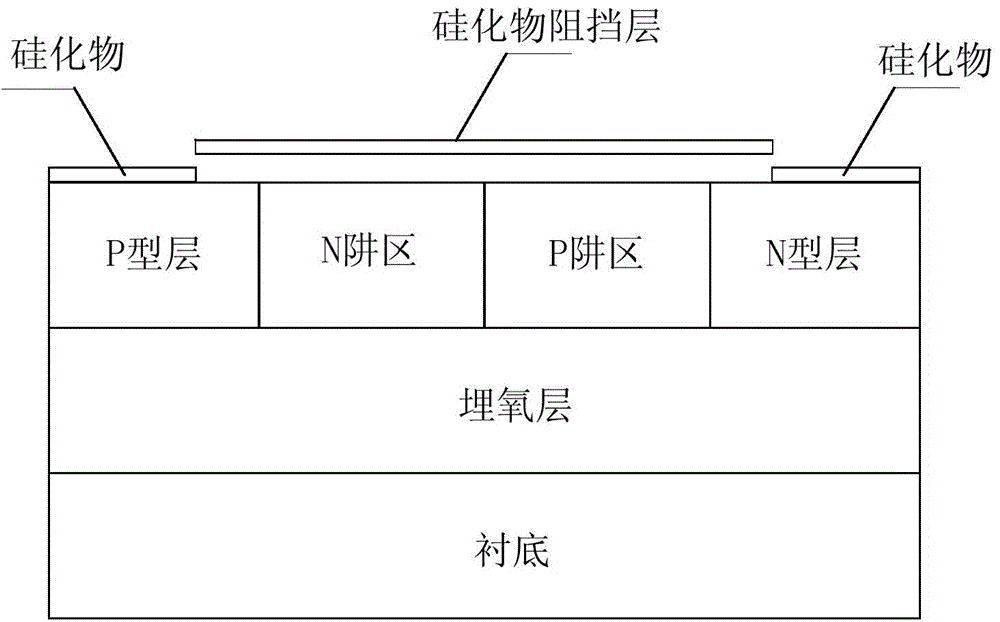

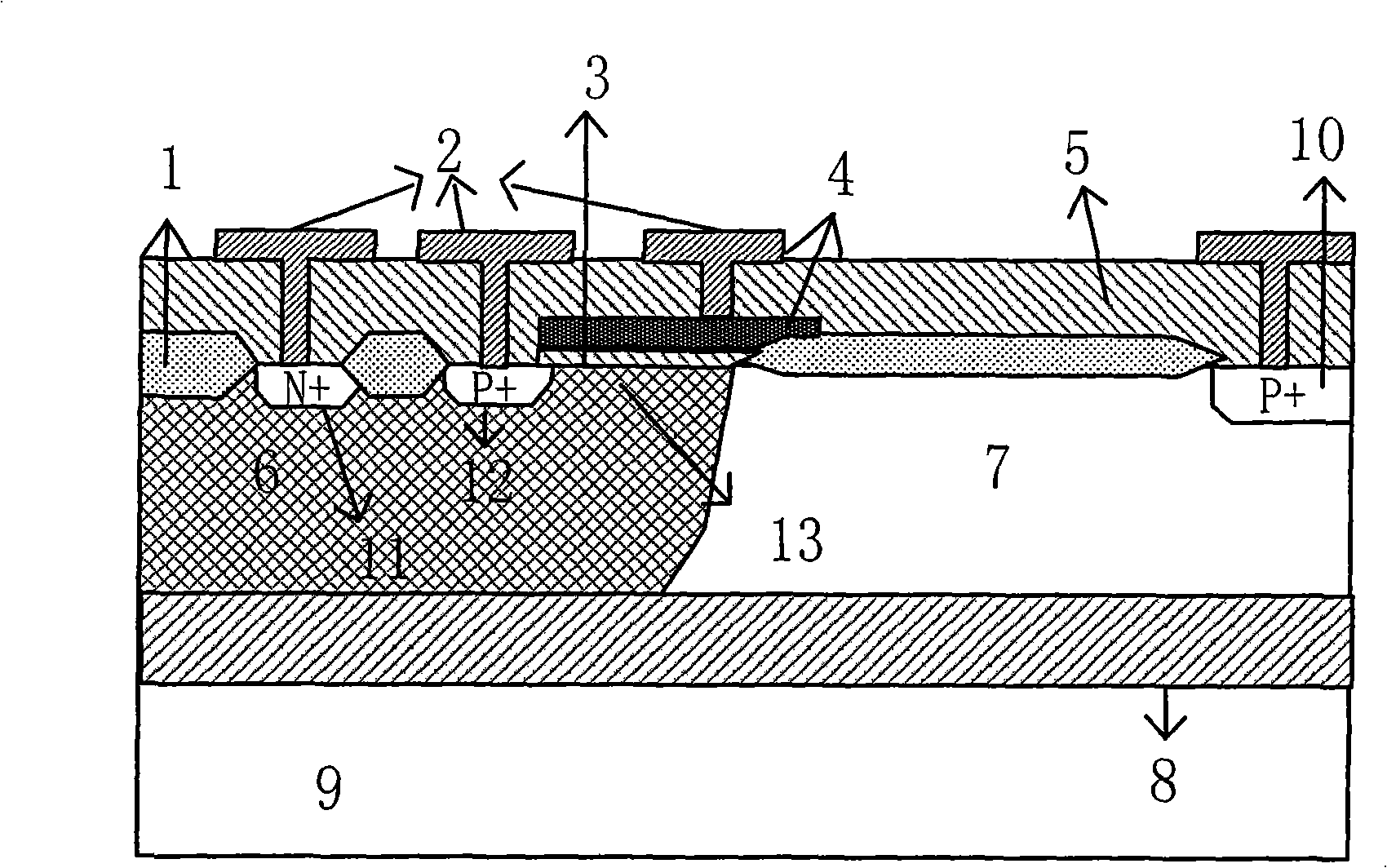

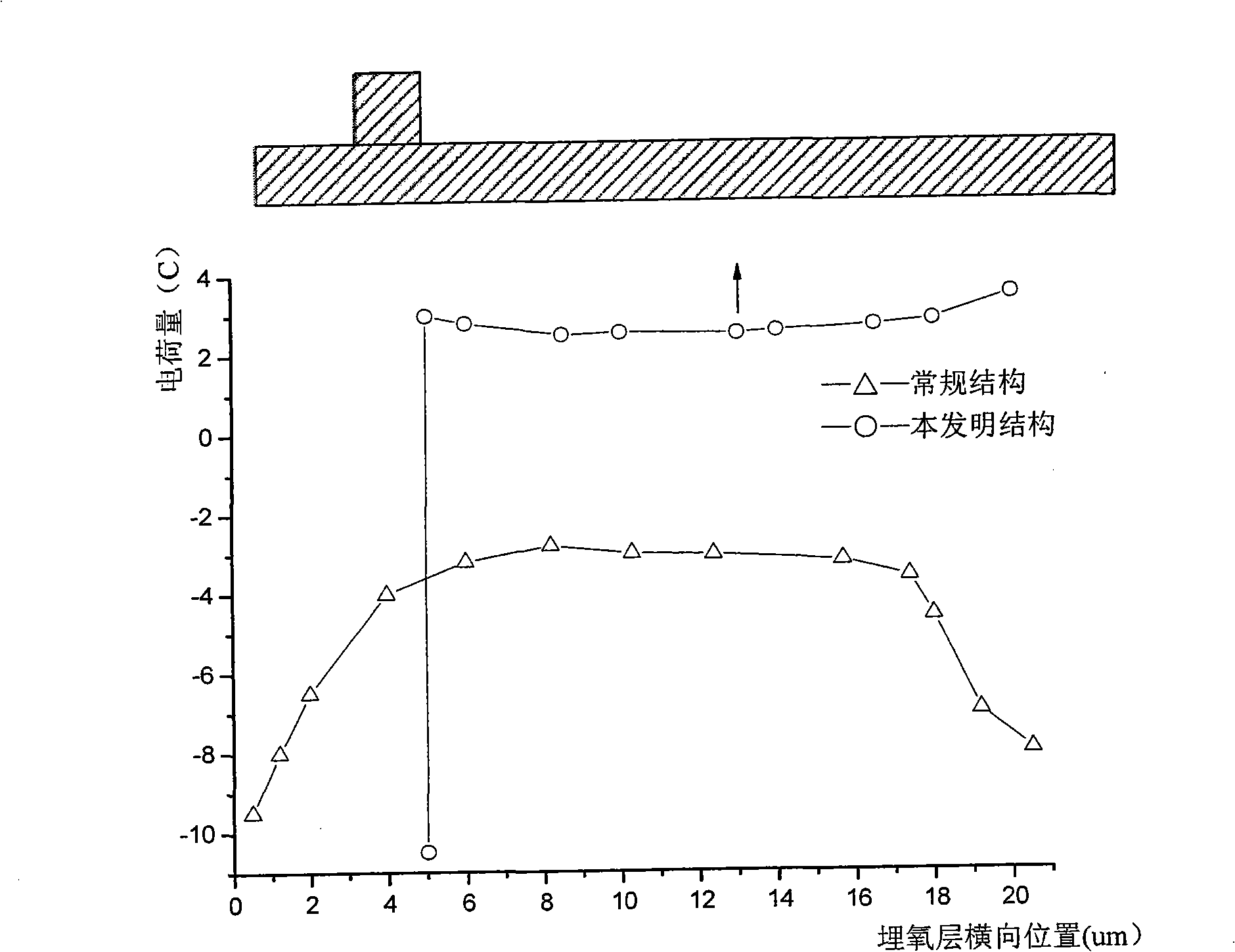

High voltage P type SOI MOS transistor

InactiveCN101488523AImprove breakdown voltageHigh charge densitySemiconductor devicesP type siliconHigh pressure

A high voltage P type silicon-on-insulator metal oxide semiconductor pipe comprises a semiconductor substrate. An insulator buried oxide layer, a P type doped semiconductor area and an N well area are arranged on the semiconductor substrate, while a field oxide layer, a metal layer, a gate oxide, a polysilicon gate and an oxide layer are arranged on the surface of the device. The metal oxide semiconductor pipe is characterized in that a barrier oxide layer is arranged on a buried oxide layer and is positioned below the gate oxide; a channel area is formed between the barrier oxide layer and gate oxide; an N type inversion layer is arranged in the P type doped semiconductor area and is positioned on the lower surface of the field oxide layer between a P type drain area and a P type source area. With such a structure, electrons induced on an interface where the P type doped semiconductor area is connected with the buried oxide layer gather on the bottom of the P type doped semiconductor area, greatly increasing the charge density at the interface, therefore, a thinner buried oxide layer can bear higher vertical breakdown voltage.

Owner:SOUTHEAST UNIV

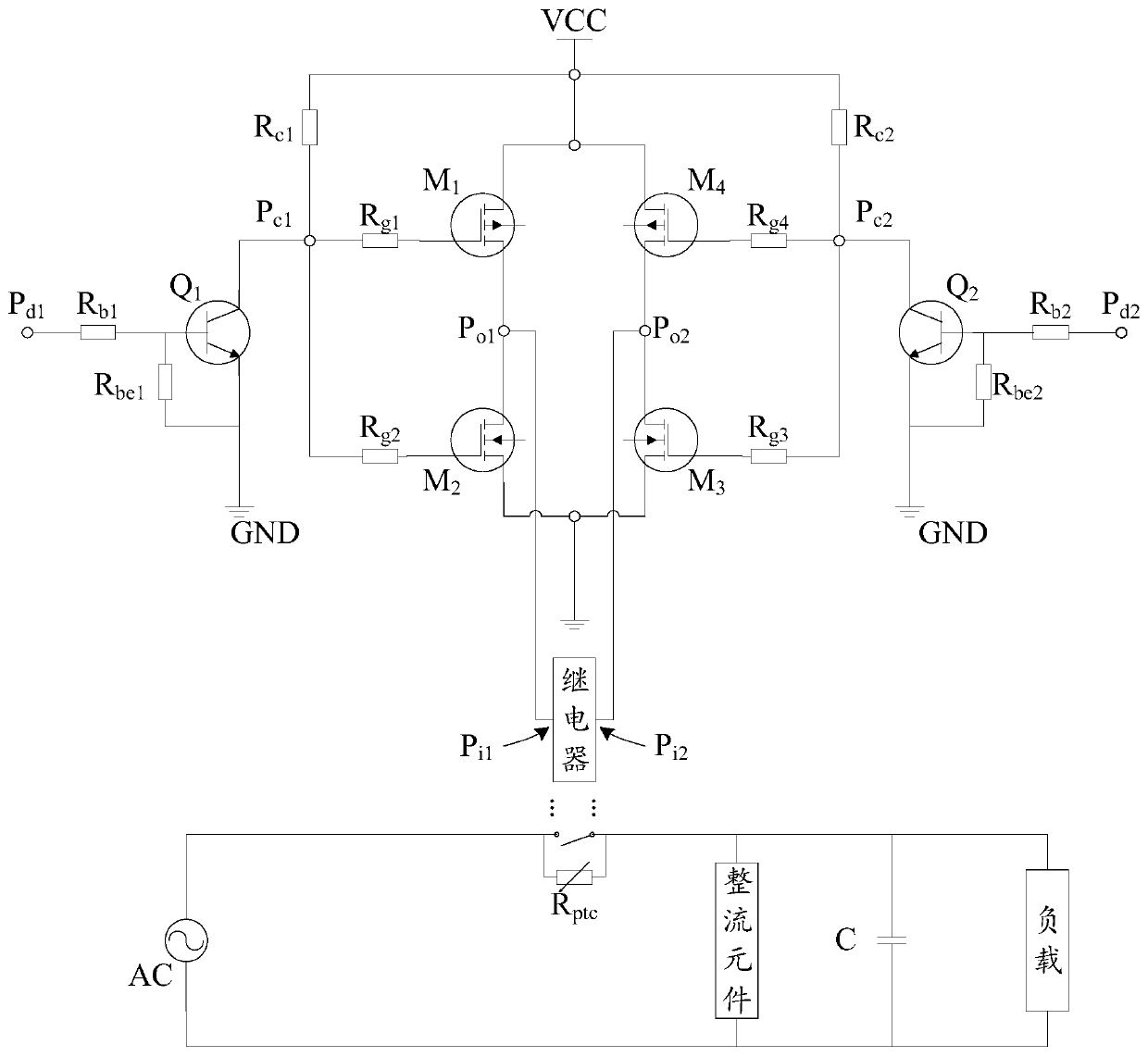

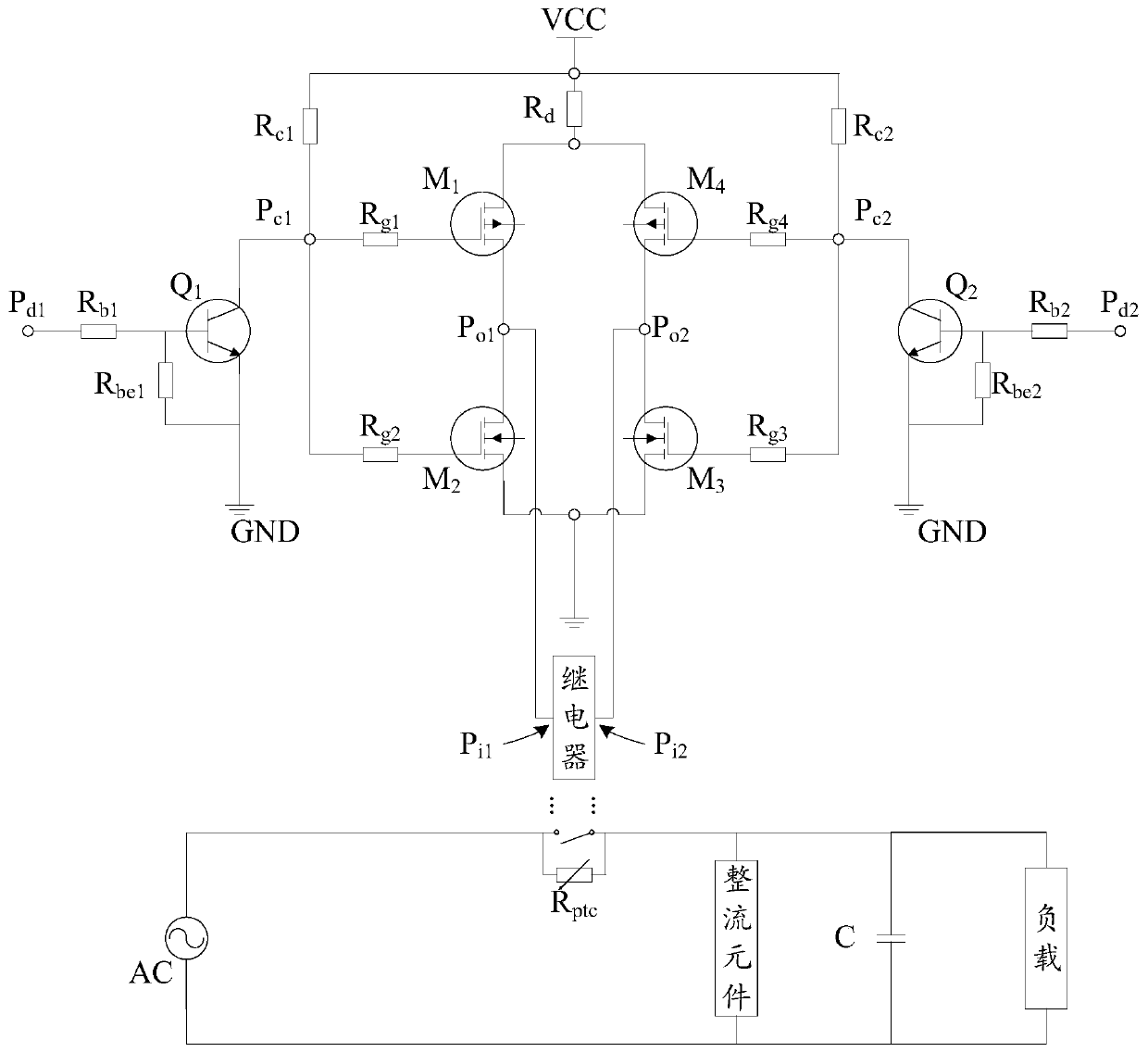

Driving control circuit and household appliance

PendingCN109743051AExtended service lifeReduce energy consumptionTransistorElectronic switchingPower gridLife time

The invention provides a drive control circuit and a household appliance, the drive control circuit comprises a self-holding relay, whereina moving contact of the self-holding relay is connected to apower grid system, and the power grid system can be controlled to supply power to a load; a Bridge circuit, wherein The bridge circuit is configured to output a pulse signal to the control end of theself-hold relay, the pulse signal is a high-level pulse signal or a low-level pulse signal; wherein the first control end of the self-hold relay receives a high-level pulse signal; Meanwhile, when thesecond control end of the self-holding relay receives the low-level pulse signal, the moving contact of the self-holding relay performs action switching, and keeps the state after the previous actionswitching before receiving the next pulse signal, and the action switching is switched from the closing state to the opening state or from the opening state to the closing state. Through the technical scheme of the invention, the power consumption of the driving control circuit is reduced, and meanwhile, the damage risk caused by electric leakage and device temperature rise is reduced, so that the service life is prolonged.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

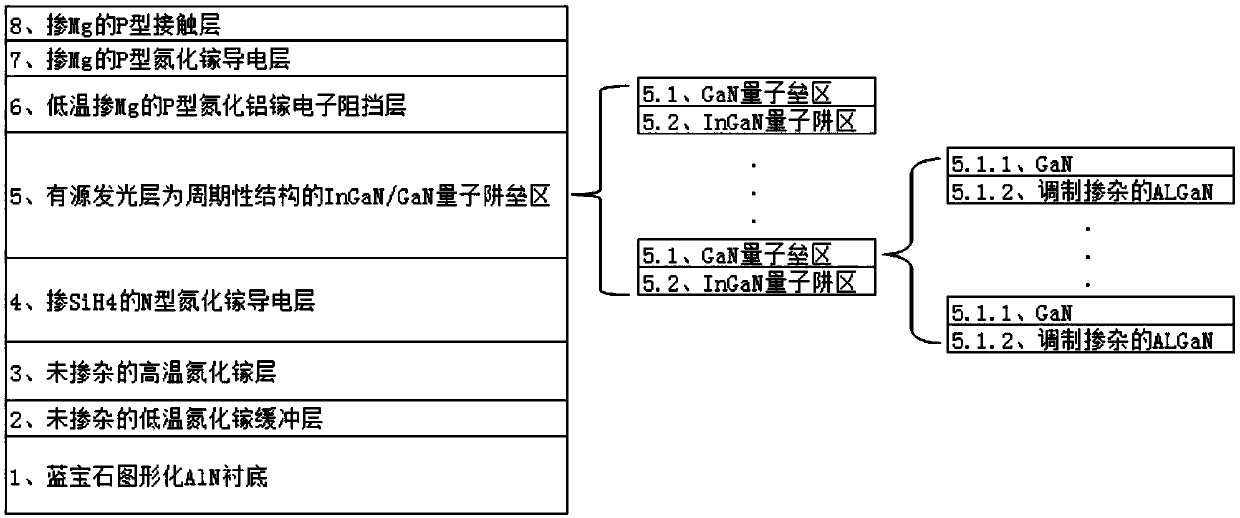

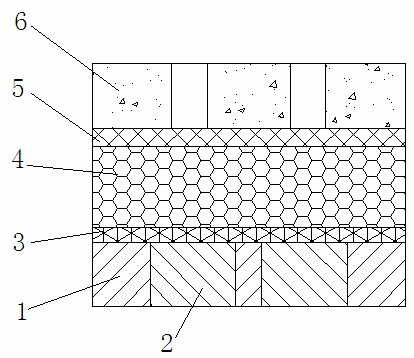

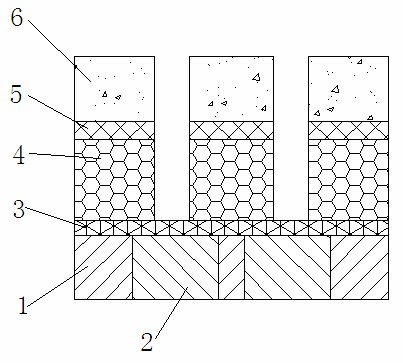

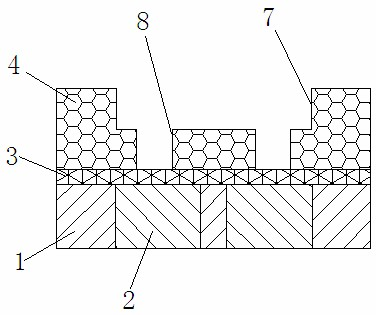

An epitaxial wafer and a growth method for improving the antistatic ability of a gallium nitride-based LED light emitting diode

InactiveCN109103310AEffective guidanceReduce the possibility of breakdownSemiconductor devicesDensity distributionContact layer

An epitaxial wafer and a growth method for improving the antistatic ability of a gallium nitride-based LED light emitting diode are provided, wherein the epitaxial wafer structure sequentially comprises a sapphire patterned AlN substrate, an undoped low-temperature gallium nitride buffer layer, an undoped high-temperature gallium nitride layer, an SiH4 doped N-type gallium nitride conductive layer, an active light emitting layer, a low-temperature Mg doped P-type aluminum gallium nitride electron blocking layer, a Mg doped P-type gallium nitride conductive layer and a Mg doped P-type contact layer from bottom to top. The invention proposes that the quantum barrier layer adopts a modulation doped GaN / AlGaN superlattice structure, which can effectively guide the impulse current, so that thepulse current is generated in the two-dimensional electron gas of GaN / AlGaN structure; the density distribution of the pulse current is more uniform because of conduction in the transverse direction,so that the possibility of LED chip breakdown is greatly reduced; the epitaxial wafer growth method is provided for effectively improving the antistatic ability of GaN-based light emitting diodes.

Owner:HUAIAN AUCKSUN OPTOELECTRONICS TECHNOLOGY CO LTD

Flame retardant yarn, fabric and clothing capable of preventing splashing of molten metal

The invention discloses a flame retardant yarn, a fabric and clothing capable of preventing the splashing of molten metal. The range of wool mass contained in the flame retardant yarn as a percentageof flame retardant viscose mass of silicone nitrogen series is 30.769%-157.895%. The flame retardant yarn, the fabric and the clothing contain the three kinds of fiber of wool, silicon nitrogen flameretardant viscose and nylon; nylon is a non-flame retardant fiber; the mass ratio of the three kinds of fiber is as follows: 20-60% of wool, 38-65% of flame retardant viscose of the silica nitrogen series, and 2-15% of nylon. The flame retardant fabric and clothing conform to the aluminum water splash test of EN ISO 9185-2008, the mass of the protective splash aluminum water is larger than or equal to 100 g, larger than or equal to 200 g or larger than or equal to 350 g, and accords with the molten iron splash test of EN ISO9185-2008, the mass of the protective splash molten iron is larger than or equal to 60 g, larger than or equal to 120 g or larger than or equal to 200 g; meanwhile the flame retardant test of EN ISO 15025-2003A1 is satisfied, the afterflame is less than or equal to 2 seconds, smoldering is less than or equal to 2 seconds, no melting and dripping phenomenon appears, and no burning holes appear; the flame retardant yarn meets the test of EN ISO 5077-2008, the washingshrinkage rate is larger than or equal to -10% and less than or equal to 10%.

Owner:南通谐好安全科技有限公司

Grid protection circuit and power electronic equipment

InactiveCN106411113AReduce failureImprove reliabilityEfficient power electronics conversionElectronic switchingEngineeringElectric power

The invention provides a grid protection circuit and power electronic equipment. The grid protection circuit comprises a main transmission line, a reference module, a comparison module, and a voltage stabilization module, wherein the main transmission line is connected between a grid driving module and the grid of an MOS transistor; the reference module is used for generating a reference signal; two input ends of the comparison module are respectively connected with the grid driving module and the reference module for comparing a grid driving signal and the reference signal; and the voltage stabilization module is connected between the output end of the main transmission line and the ground wire, and the driving end of the voltage stabilization module is connected with the output end of the comparison module. When the grid driving signal is larger than or equal to the reference signal, the comparison module outputs an on signal to the voltage stabilization module to control the voltage stabilization module to be on, the voltage stabilization module outputs a clamp voltage signal to the grid of the MOS transistor, and the clamp voltage signal is smaller than the grid driving signal. Through the technical scheme of the invention, the reliability and the accuracy of over current protection are enhanced.

Owner:MIDEA GRP CO LTD +1

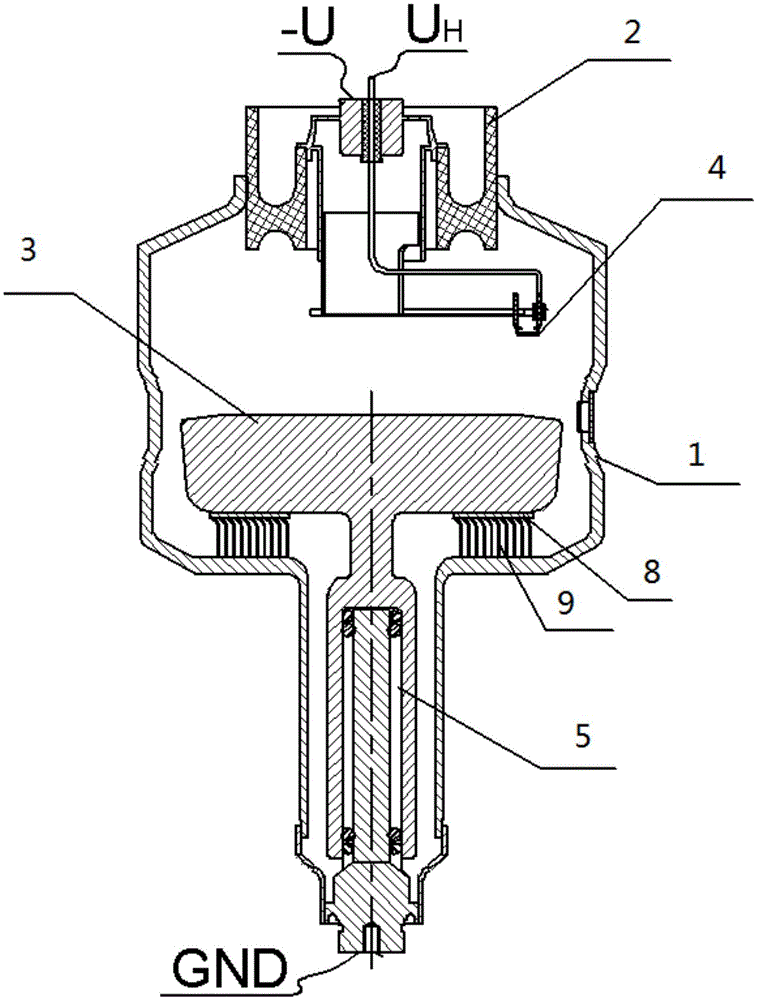

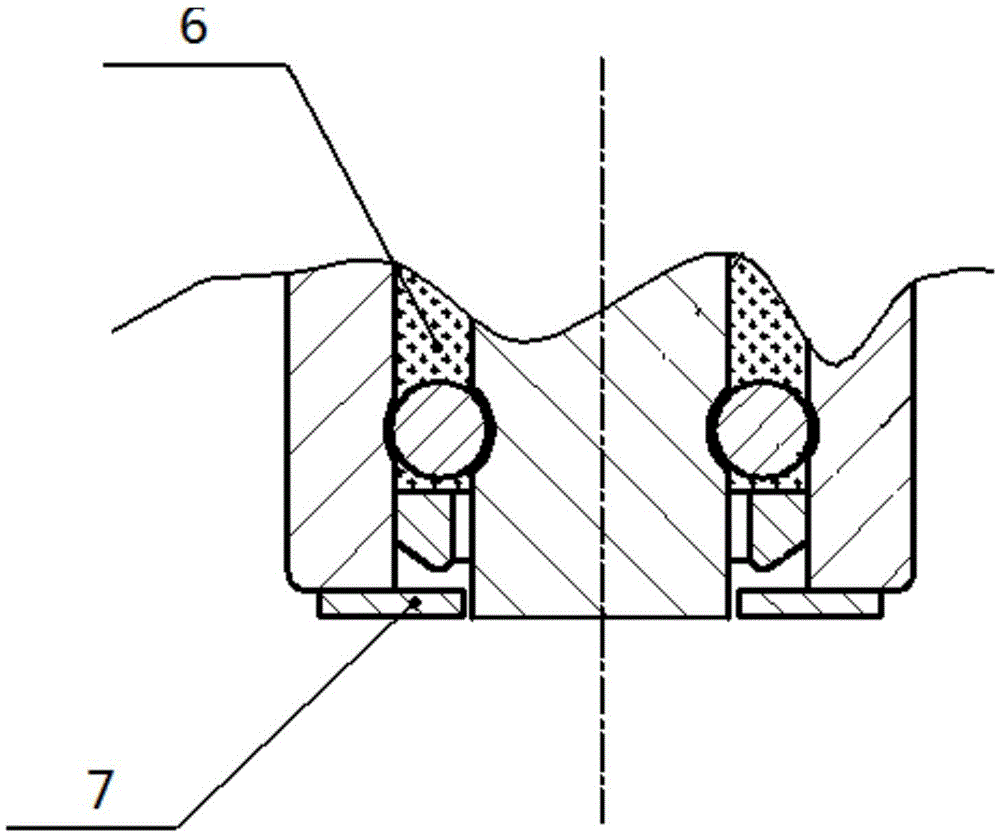

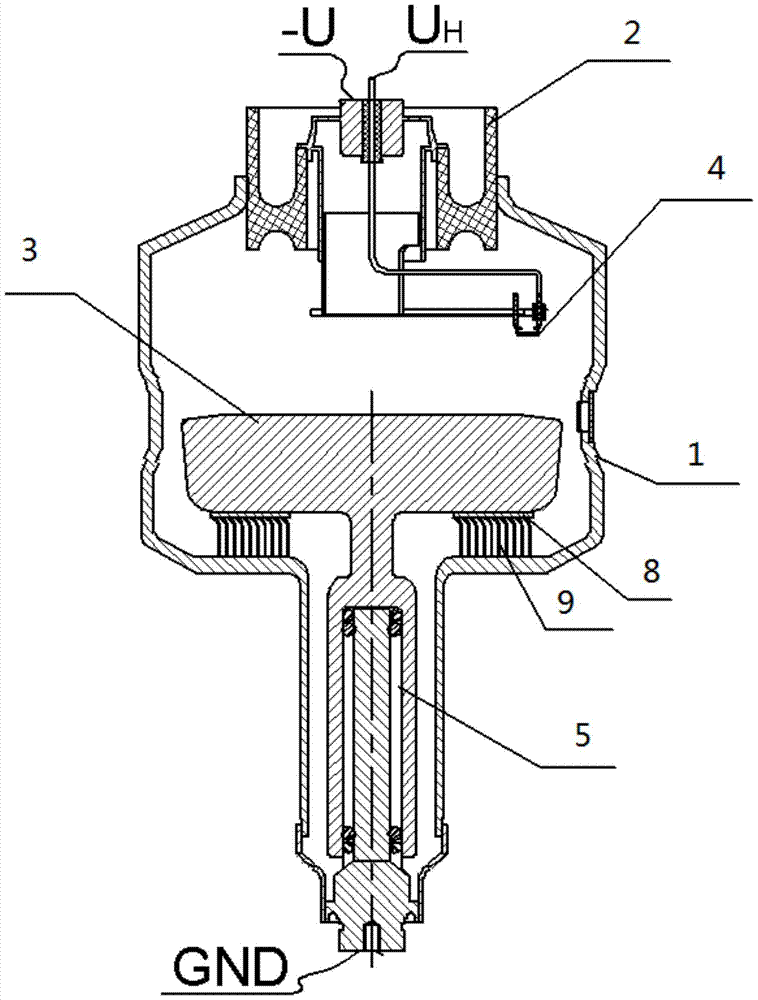

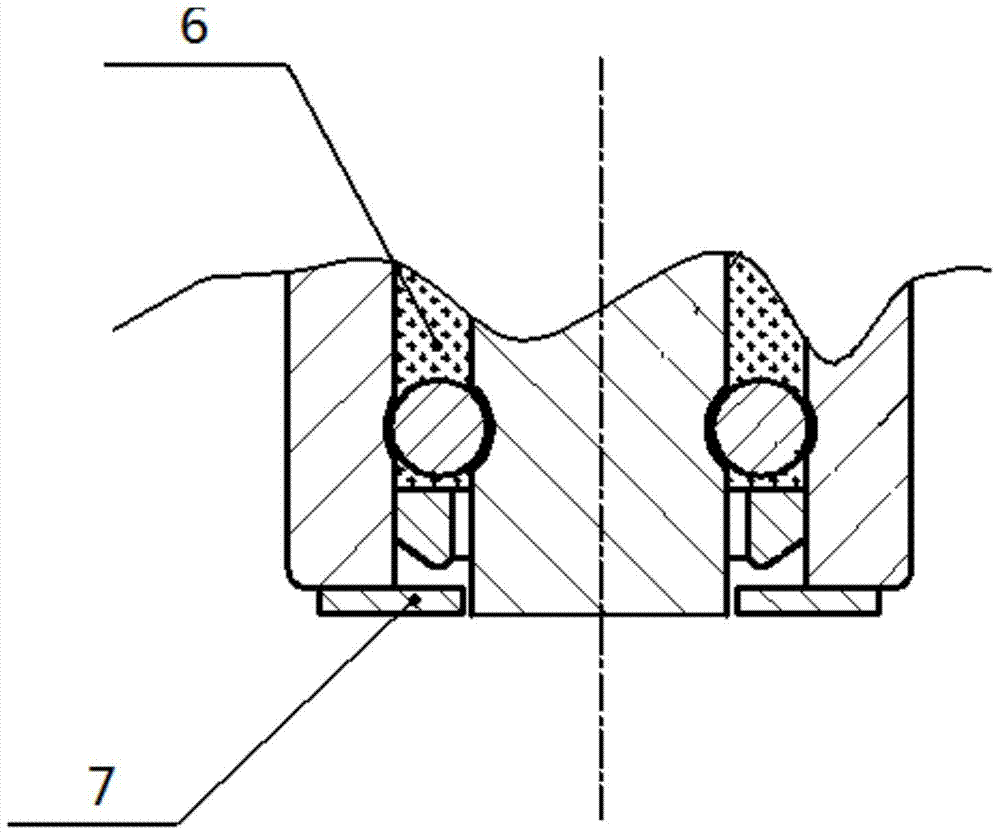

Rotating anode CT bulb tube employing elastic metal fibers and graphene for improving heat dissipation

ActiveCN105470079ANot easy to burstImprove thermal conductivityX-ray tube electrodesX-ray tube vessels/containerMetal fibersGraphene

The invention discloses a rotating anode CT bulb tube employing elastic metal fibers and graphene for improving heat dissipation, and belongs to the field of vacuum electronic medical devices. The bulb tube mainly comprises a tube housing, a rotating anode target connected in the tube housing, and a cathode which is located in the tube housing and is opposite to the rotating anode target. The rotating anode target is connected with the tube housing through a bearing. The tube housing comprises a cathode ceramic segment and a metal segment. The cathode ceramic segment is in a cylindrical structure with a central hole, and two ends of the cathode ceramic segment are respectively provided with an annular groove. The depth of one annular groove at one end of the interior of the metal segment is less than the depth of the annular groove at one end of the exterior of the metal segment. Moreover, an inner end face of the annular groove at the end of the exterior of the metal segment is lower than an outer end face. Nano-level graphene powder is disposed in a bearing ball cavity, and two ends of the bearing ball cavity are provided with stopping pieces. The elastic metal fibers are disposed between the surface of the rotating anode target and the opposite surface of the tube housing, and contact with the tube housing and a target head.

Owner:电科睿视技术(北京)有限公司

Method for increasing breakdown voltage of double-Damascus structure dielectric barrier layer film

InactiveCN102446840AReduce the possibility of breakdownSemiconductor/solid-state device manufacturingDielectricHydrogen content

The invention discloses a method for increasing breakdown voltage of a double-Damascus structure dielectric barrier layer film. In the method, the deposited dielectric barrier layer is made of high-tensile stress silicon nitride; and the H content in the Si-H bond and the N-H bond in the silicon nitride is smaller than 20 percent. With the using of the method for increasing the breakdown voltage of the double-Damascus structure dielectric barrier layer film, the H content in the Si-H bond and the N-H bond in a dielectric barrier layer formed by the silicon nitride is smaller than 20 percent, and with the reducing of the low hydrogen content, in actual application, the probability that the dielectric barrier layer is broken down by the electricity is greatly reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

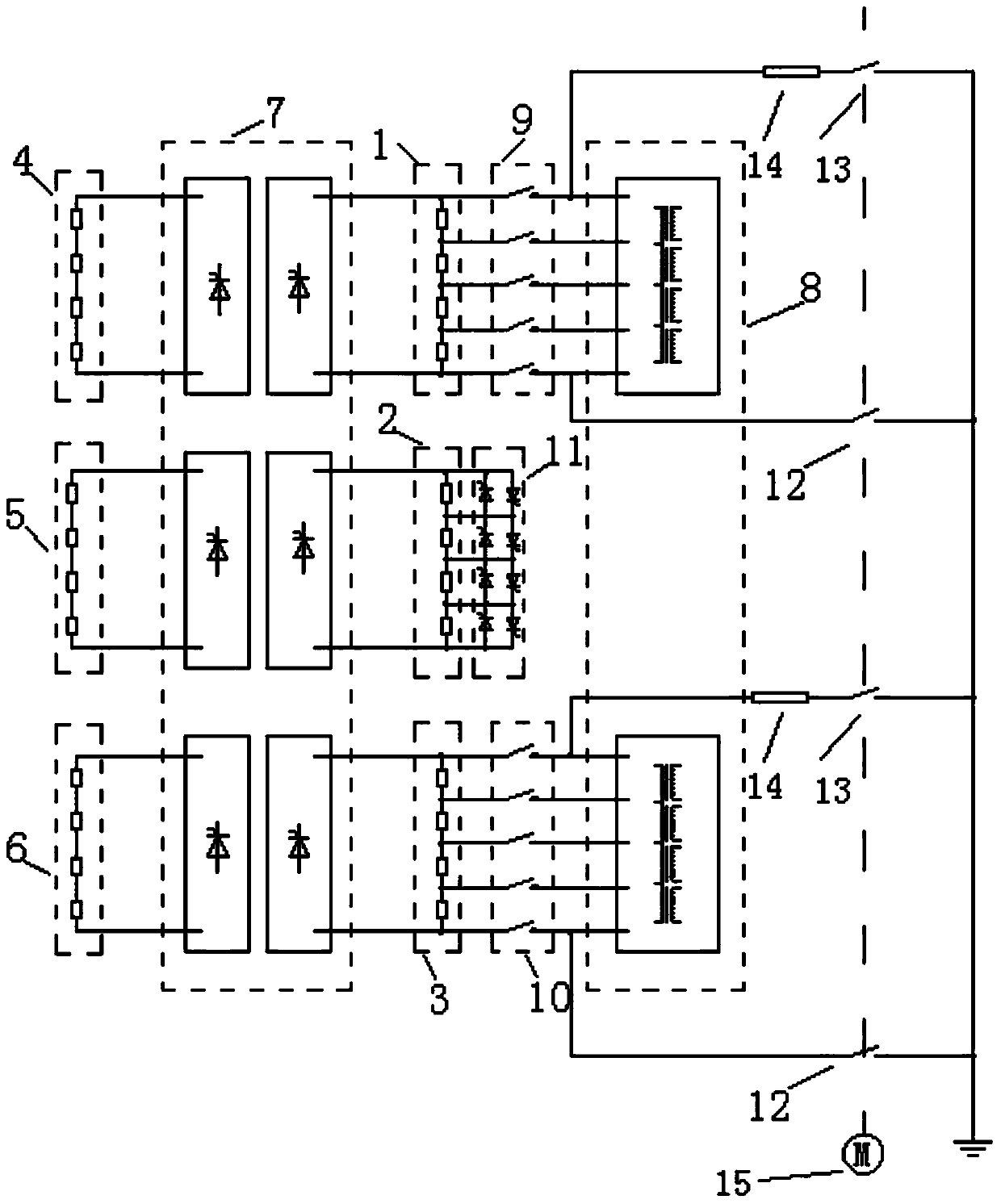

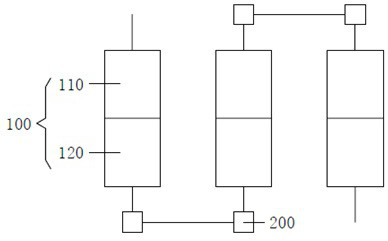

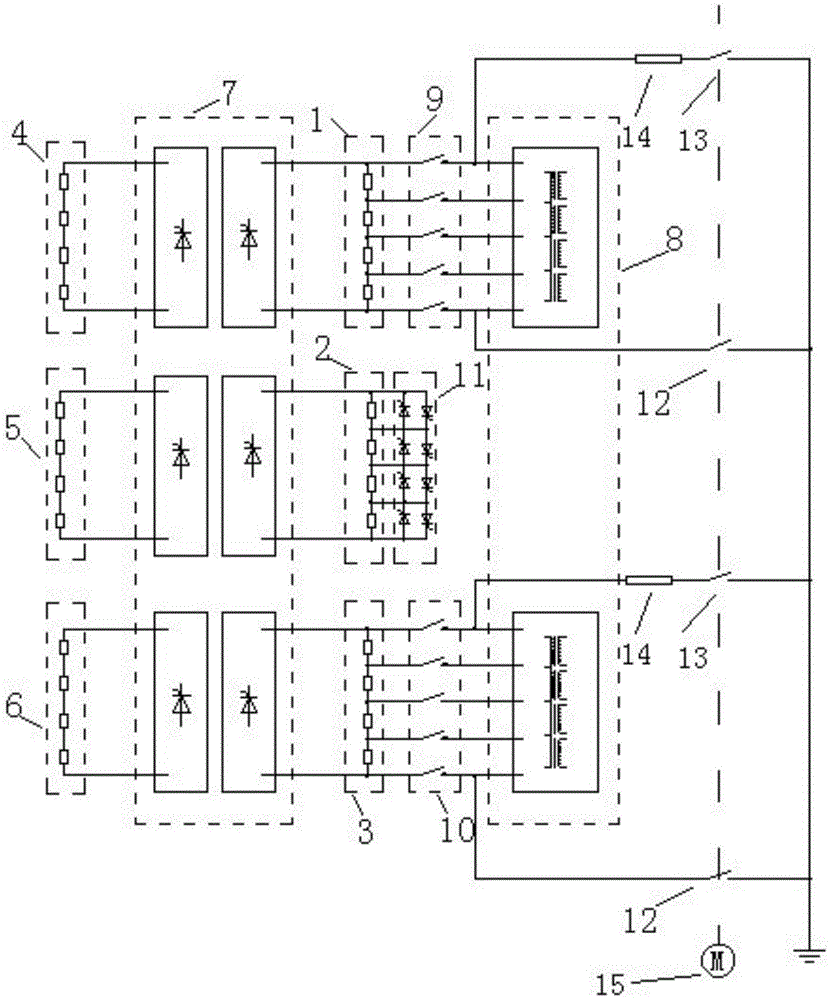

Electrical system and starting method of reduction furnace with polycrystalline silicon rods

InactiveCN104003394AAvoid potential risksReduce the possibility of breakdownSilicon compoundsElectricityMetallurgy

The invention discloses an electrical system of a reduction furnace with polycrystalline silicon rods and a starting method of the reduction furnace with the polycrystalline silicon rods, and particularly relates to the starting method of the reduction furnace with the twenty-four pairs of polycrystalline silicon rods. The electrical system comprises the twenty-four pairs of polycrystalline silicon rods, wherein the four pairs of polycrystalline silicon rods are distributed on an inner ring, the eight pairs of polycrystalline silicon rods are distributed on a middle ring, and the twelve pairs of polycrystalline silicon rods are distributed on an outer ring; the twenty-four pairs of polycrystalline silicon rods are all connected with a power-adjusting-cabinet power source, the eight pairs of polycrystalline silicon rods distributed on the middle ring are further connected with a high-voltage starting power source through a middle-ring isolating switch, the four pairs of polycrystalline silicon rods distributed on the inner ring are further connected with four sets of thyristor modules, and each pair of polycrystalline silicon rods on the inner ring corresponds to a set of antiparallel thyristors. According to the method, after the middle ring is broken down through a high voltage, electricity is completely supplied by a normal power source, breakdown is conducted on the inner ring in an alternating mode under the baking action of the middle ring, and the outer ring is directly started under the baking action of the inner ring and the middle ring after the inner ring is broken down.

Owner:SHAANXI TIANHONG SILICON IND

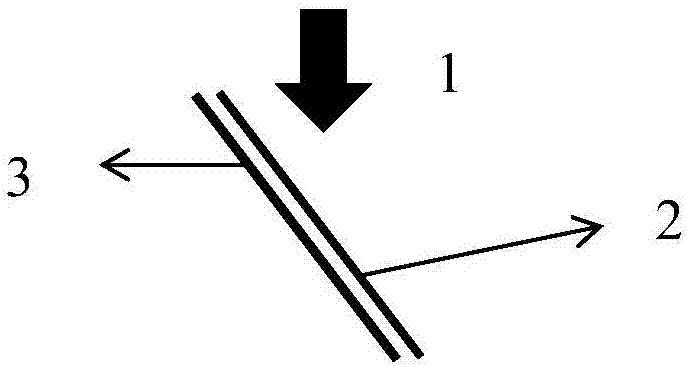

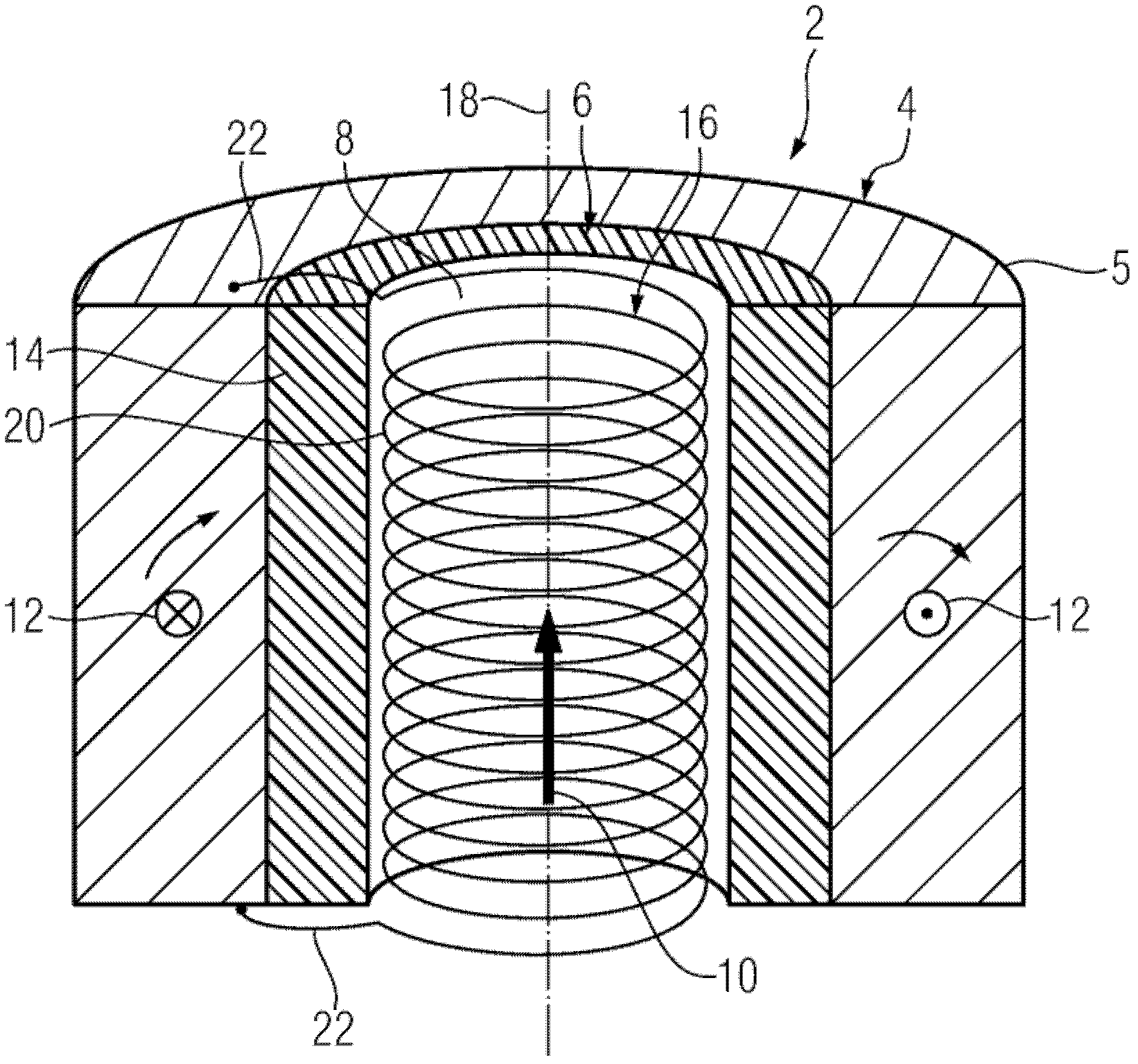

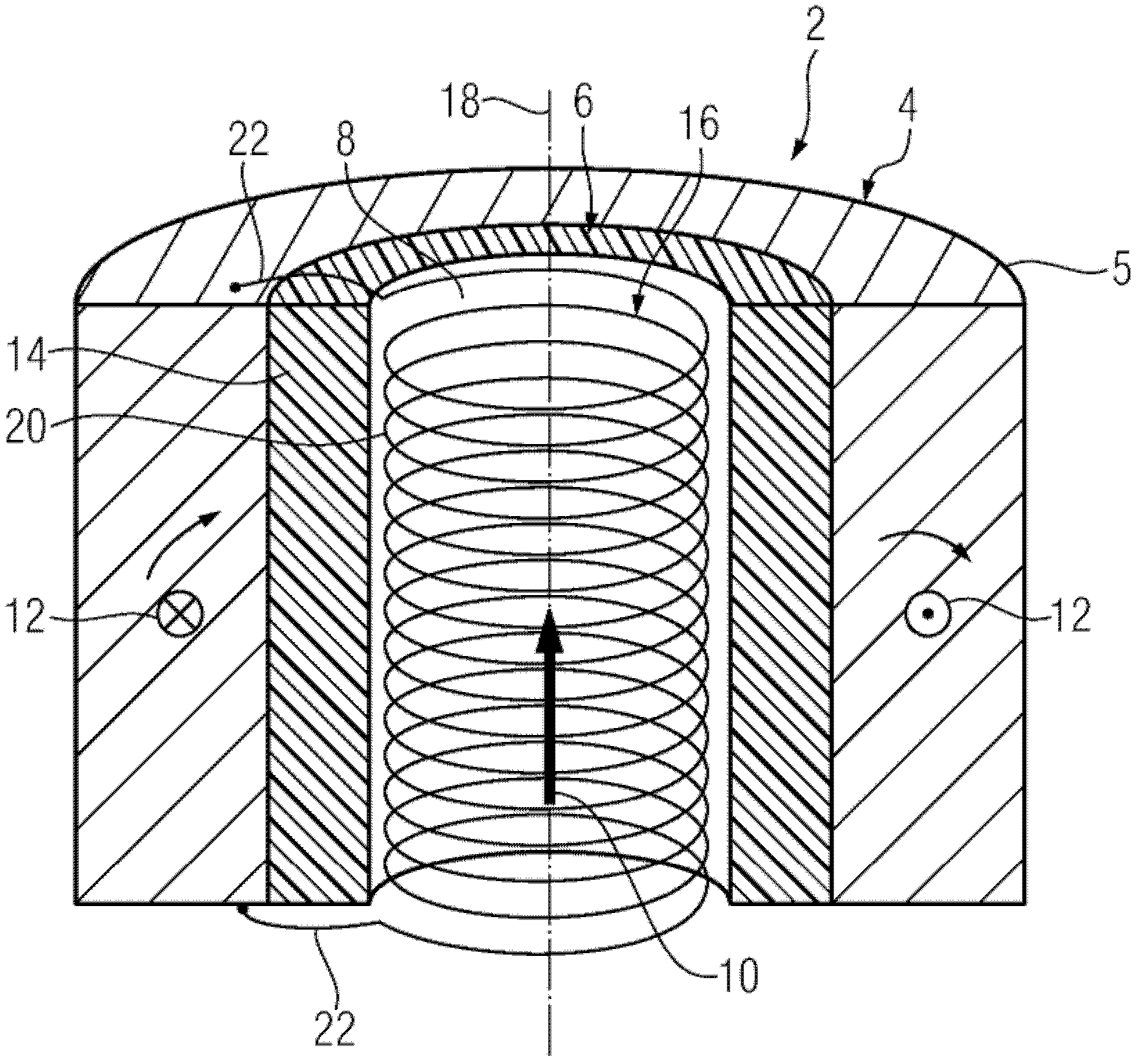

Radiation tubes and particle accelerators with radiation tubes

InactiveCN102293067ANo potential differenceEasy to manufactureElectric discharge tubesDirect voltage acceleratorsParticle acceleratorElectrical conductor

A radiant tube (4) for guiding a charged particle stream (10) has a hollow cylindrical isolation core (6) directly encompassing a beam-guiding hollow volume (8). The isolation core (6) is formed from a dielectrically acting carrier substrate (14) and an electrical conductor (16) held therein. The conductor (16) is divided into a plurality of conductor loops (20) completely encompassing the circumference of the isolation core (6) at different axial positions of the isolation core (6). The conductor loops (20) are galvanically connected to each other.

Owner:SIEMENS AG

High-voltage double-diffused metal-oxide-semiconductor (DMOS) device

InactiveCN102044562AImprove breakdown voltageLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesGate oxideBreakdown voltage

The invention discloses a high-voltage double-diffused metal-oxide-semiconductor (DMOS) device, comprising a drift region, a drain region, a channel region, a source region, a gate oxidation layer, a gate and a buried layer, wherein the drift region is positioned between the channel region and the gate region; the source region is formed on the channel region; and the buried layer is buried in the drift region and connected with the channel region. The buried layer and the channel region is respectively provided with a first conducting type, and the source region, the drain region and the drift region are respectively provided with a second conducting type. The buried layer can guide high potential of the drift region introduced by the drain region to a deep part of the drift region, so that the electric field of the drift region is two-dimensionally uniformly distributed, the accumulation of the electric field on the surface of the drift region is reduced, and therefore, the breakdown probability occurring on the surface of the drift region is reduced, and the breakdown voltage is increased. On the basis of increasing the breakdown voltage, by increasing the doping concentration of the drift region or reducing the size of the device, the on resistance of the DMOS can be reduced and the characteristics of the device can be improved.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

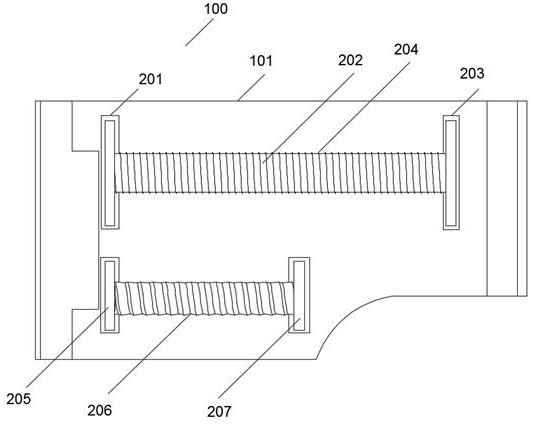

Device and method for manufacturing high-capacity high-frequency-resistant low-loss electromagnetic wire

InactiveCN112466563AQuality assuranceUniform thicknessApparatus for heat treatmentManufacturing extensible conductors/cablesCopper wireCopper-wiring

The invention discloses a device for manufacturing a high-capacity high-frequency-resistant low-loss electromagnetic wire in the technical field of electromagnetic wires, and the device comprises a plurality of painting and baking assemblies, wherein the painting and baking assembly at the leftmost end corresponds to an annealing device, and the painting and baking assembly comprises a paint box and a baking box; an outlet of the paint box corresponds to an inlet of the baking box, and a copper wire enters the baking box from the inlet of the paint box, then enters the baking box from the outlet of the paint box and penetrates out of the baking box from the outlet of the baking box; after passing through the painting and baking assembly at the leftmost end, the copper wire enters the remaining painting and baking assemblies in an S shape to be painted and baked, and the thickness of a paint layer on the copper wire is consistent through multiple times of painting, baking and paint scraping. The device comprises a plurality of guide assemblies, and the guide assemblies are corresponding to the painting and baking assemblies. According to the painting and baking device for the electromagnetic wire, it can be effectively guaranteed that the thickness of the upper side layer of the electromagnetic wire is uniform, the quality of the electromagnetic wire is guaranteed, and the possibility of breakdown is reduced.

Owner:安徽聚虹电器有限公司

Flame Retardant Yarns, Fabrics, Clothing Against Molten Metal Splash

The invention discloses a flame retardant yarn, a fabric and clothing capable of preventing the splashing of molten metal. The range of wool mass contained in the flame retardant yarn as a percentageof flame retardant viscose mass of silicone nitrogen series is 30.769%-157.895%. The flame retardant yarn, the fabric and the clothing contain the three kinds of fiber of wool, silicon nitrogen flameretardant viscose and nylon; nylon is a non-flame retardant fiber; the mass ratio of the three kinds of fiber is as follows: 20-60% of wool, 38-65% of flame retardant viscose of the silica nitrogen series, and 2-15% of nylon. The flame retardant fabric and clothing conform to the aluminum water splash test of EN ISO 9185-2008, the mass of the protective splash aluminum water is larger than or equal to 100 g, larger than or equal to 200 g or larger than or equal to 350 g, and accords with the molten iron splash test of EN ISO9185-2008, the mass of the protective splash molten iron is larger than or equal to 60 g, larger than or equal to 120 g or larger than or equal to 200 g; meanwhile the flame retardant test of EN ISO 15025-2003A1 is satisfied, the afterflame is less than or equal to 2 seconds, smoldering is less than or equal to 2 seconds, no melting and dripping phenomenon appears, and no burning holes appear; the flame retardant yarn meets the test of EN ISO 5077-2008, the washingshrinkage rate is larger than or equal to -10% and less than or equal to 10%.

Owner:南通谐好安全科技有限公司

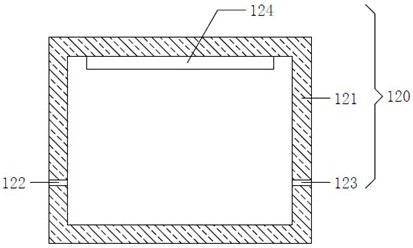

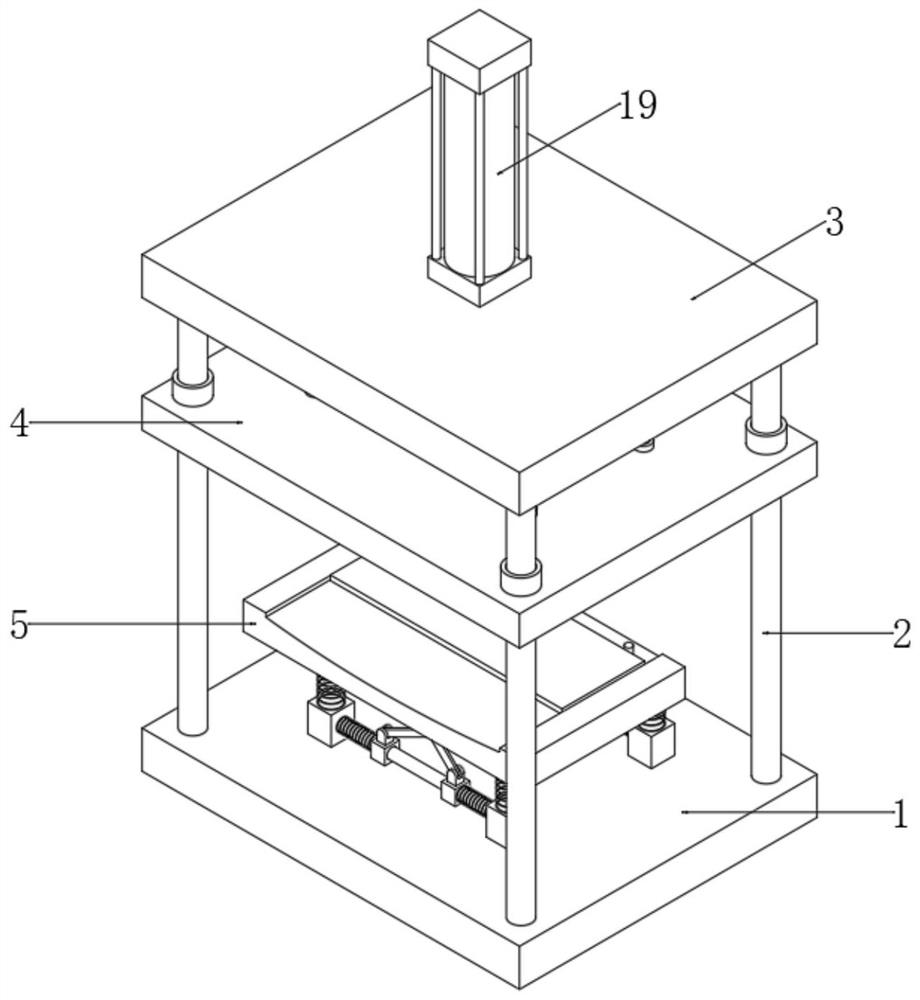

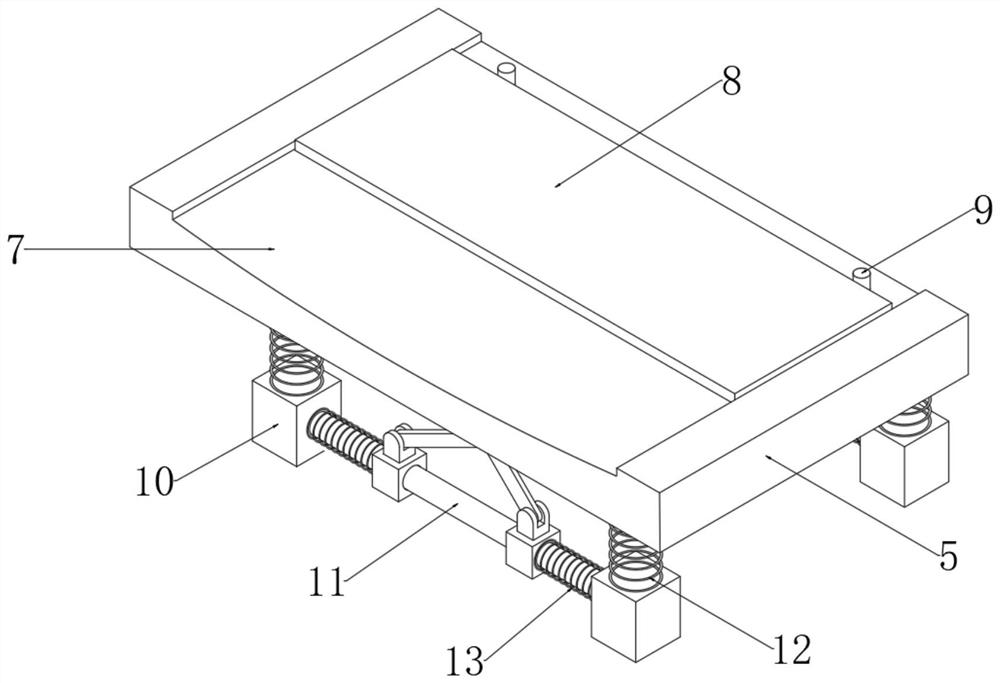

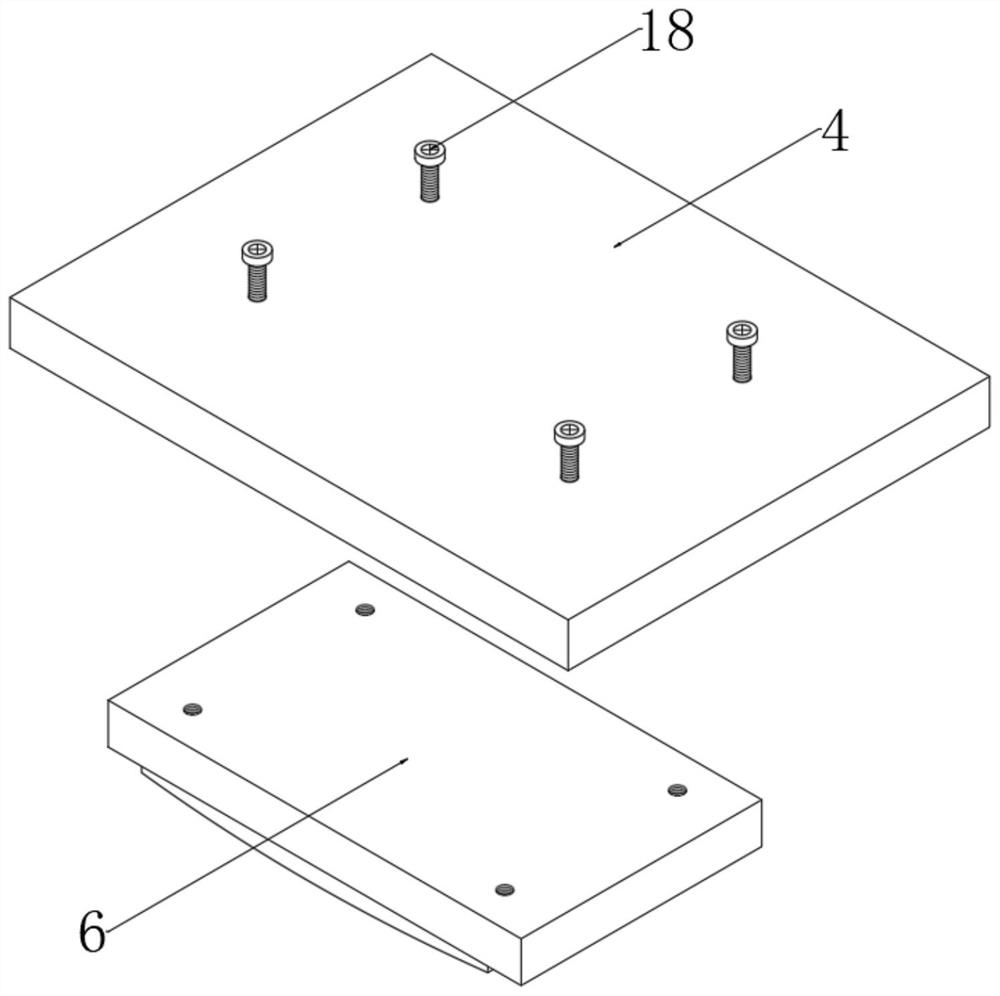

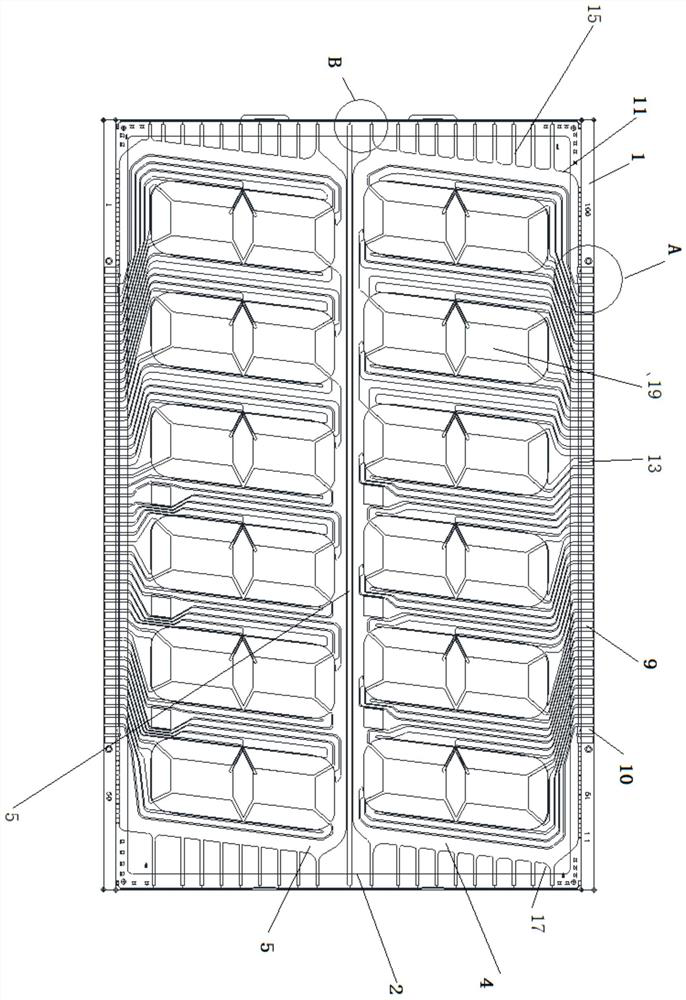

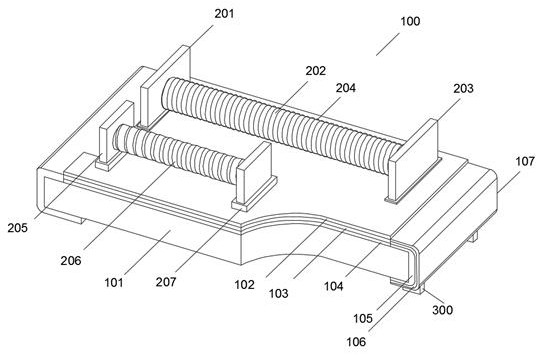

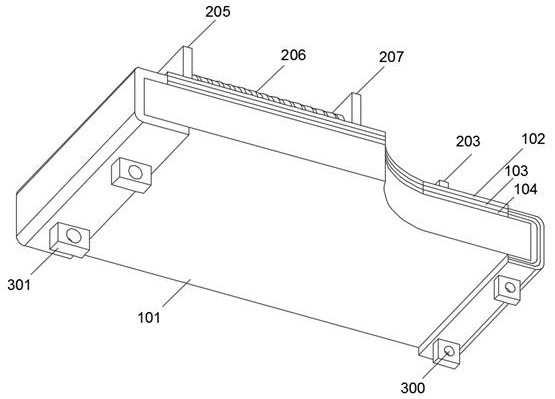

Graphite fuel cell panel flatness correction device

PendingCN114068975AEnsure safetyReduce the possibility of breakdownNon-rotating vibration suppressionWorking accessoriesFuel cellsStructural engineering

The invention relates to the technical field of graphite fuel cell panels, and discloses a graphite fuel cell panel flatness correction device which comprises a fixed base, a mounting plate is arranged over the fixed base, a correction assembly is arranged between the fixed base and the mounting plate, and the correction assembly comprises a lower device body, an upper device body, a placement groove and two positioning pins, a battery panel body is movably arranged in the placement groove in a sleeving manner, and a damping mechanism is arranged between the fixed base and the lower device body. According to the graphite fuel cell panel flatness correction device, through design of the correction assembly and the damping mechanism, the flatness of a bipolar plate can be controlled within 0.1 MM through the correction assembly in the device, so that the contact resistance of a product after assembly is reduced, the contact surface of a membrane electrode and the bipolar plate can be stressed more uniformly, the possibility that the membrane electrode is broken through is reduced, meanwhile, different pressure maintaining time and curved surface radians can be set according to different deformation amounts of the bipolar plate and different plate thicknesses.

Owner:安徽锦美碳材科技发展有限公司

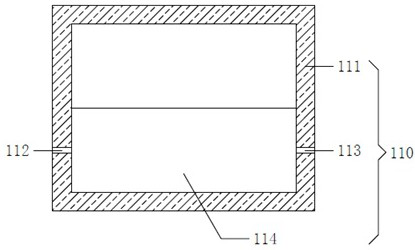

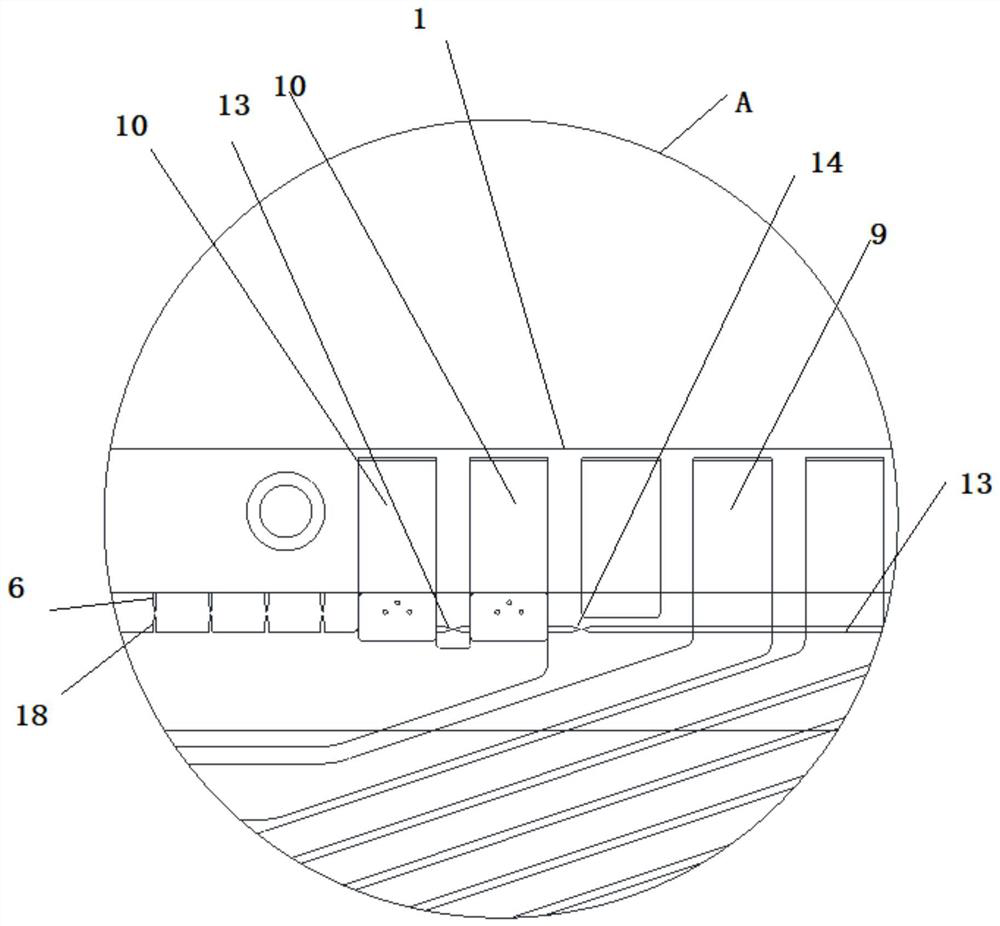

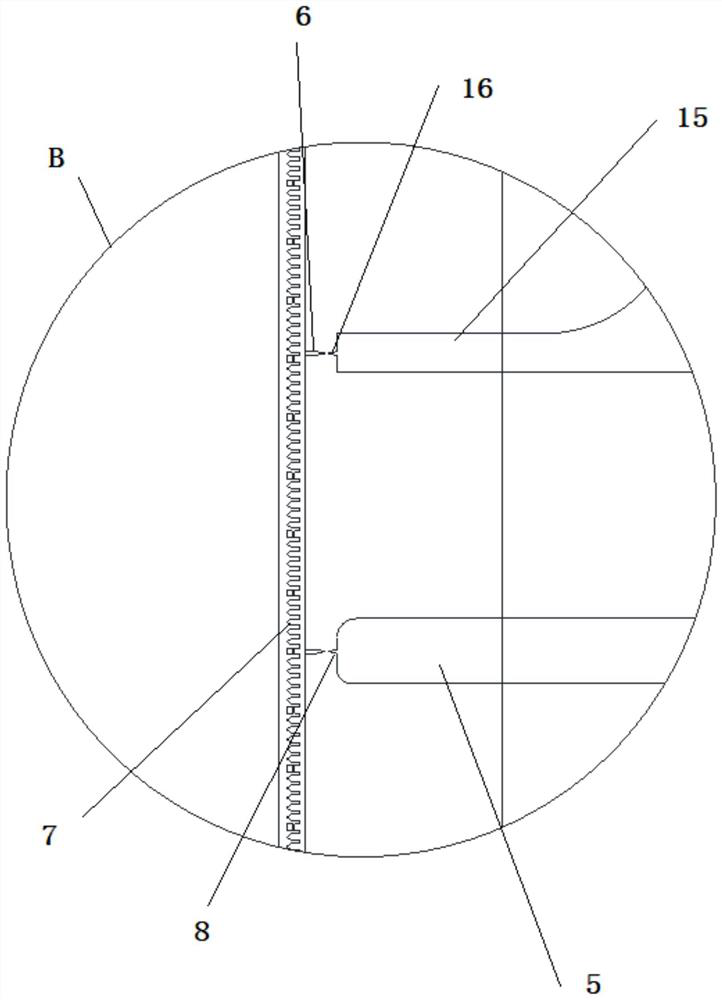

Static split-screen type LCD display screen

PendingCN112631012AEfficient releaseImprove anti-static performanceElectrostatic discharge protectionNon-linear opticsMechanical engineeringMaterials science

The invention discloses a static split-screen type LCD display screen which comprises an LCD glass body and a display area arranged in the middle of the LCD glass body, the display area comprises an upper display area and a lower display area, and pattern display parts are arranged in the middle of the upper display area and the middle of the lower display area. A group of glass outer edge discharge tips are arranged on the outer side of the edge of the LCD glass body; and a display area separation line is arranged between the upper display area and the lower display area, a set of glass inner edge discharge tips are distributed around the inner side of the edge of the LCD glass body, and the left end and the right end of the display area separation line are each provided with a separation discharge tip matched with the corresponding glass inner edge discharge tip. The split-screen LCD can effectively solve the problems that an existing split-screen LCD is poor in discharging effect, the anti-static effect is equal to that of the existing split-screen LCD, PI breakdown is likely to occur, black and white points are formed, the screen reality effect is similar to light leakage, the split-screen LCD becomes a waste product, and the yield of products is affected.

Owner:ANHUI GOLDEN VISION OPTOELECTRONICS TECH

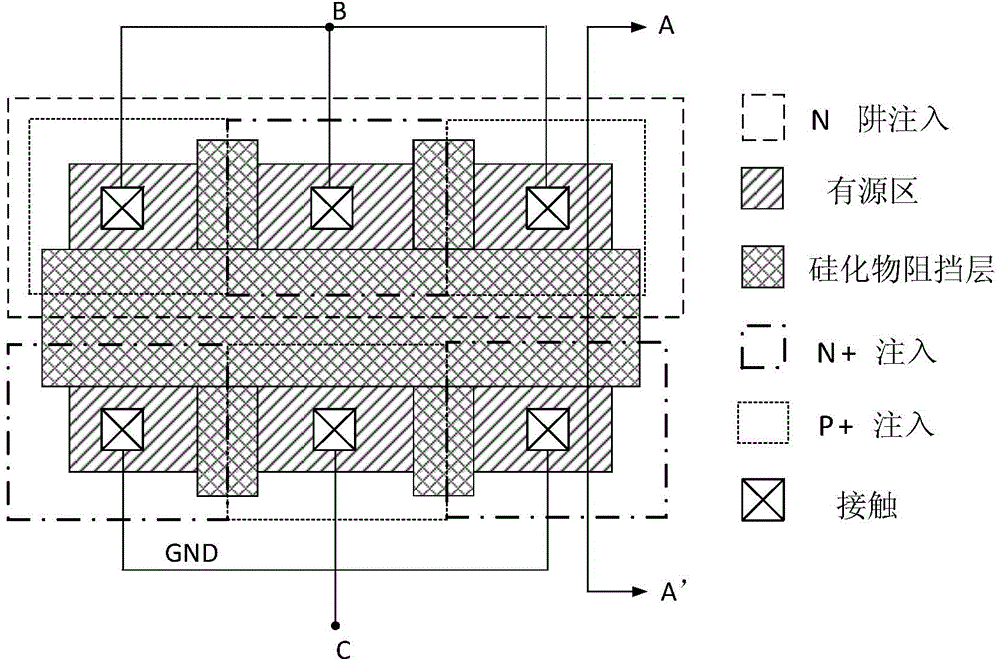

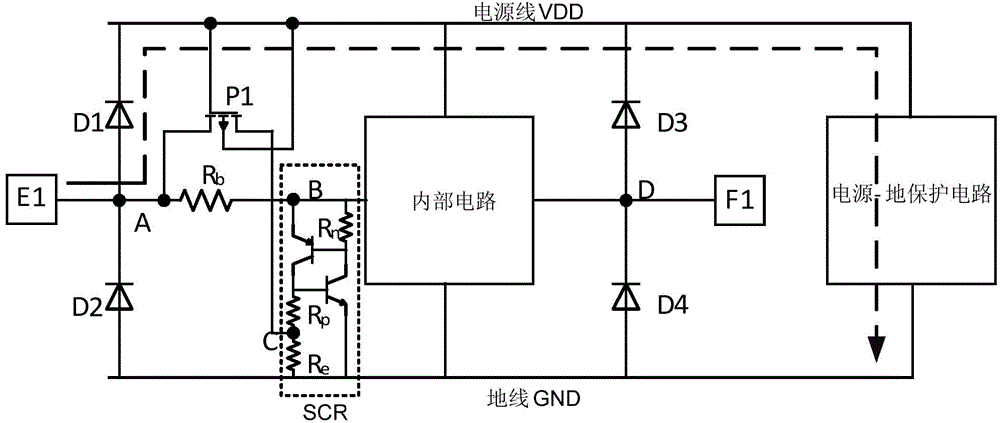

SOI ESD two-stage protection network

ActiveCN104465651AImprove anti-ESD protection abilityReduce the possibility of breakdownSolid-state devicesSemiconductor devicesSilicon-controlled rectifierGrating

The invention provides an SOI ESD two-stage protection network. The SOI ESD two-stage protection network comprises a first-stage protection network and a second-stage protection network, wherein the first-stage protection network is composed of a first diode and a second diode, the second-stage protection network comprises a PMOS transistor, an external resistor, a buffer resistor and a silicon control rectifier, the first end of the buffer resistor is connected with the input end of the first protection network, the second end of the buffer resistor is connected with the P type layer and the N well region of the silicon control rectifier and serves as the output end of the second-stage protection network, the grating end and the body end of the PMOS transistor are connected with a power line, the source end of the PMOS transistor is connected with the input end of the second-stage protection network, the drain terminal of the PMOS transistor is connected with the first end of the external resistor and connected with the P well region of the silicon control rectifier, the second end of the external resistor is connected with a ground wire, and the N type layer of the silicon control rectifier is connected with the ground wire. The dynamic trigger principle is adopted for the SOI silicon control rectifier, the reaction speed of the second-stage protection can be greatly increased, and the possibility that the internal circuit gate breakdown can be greatly lowered.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

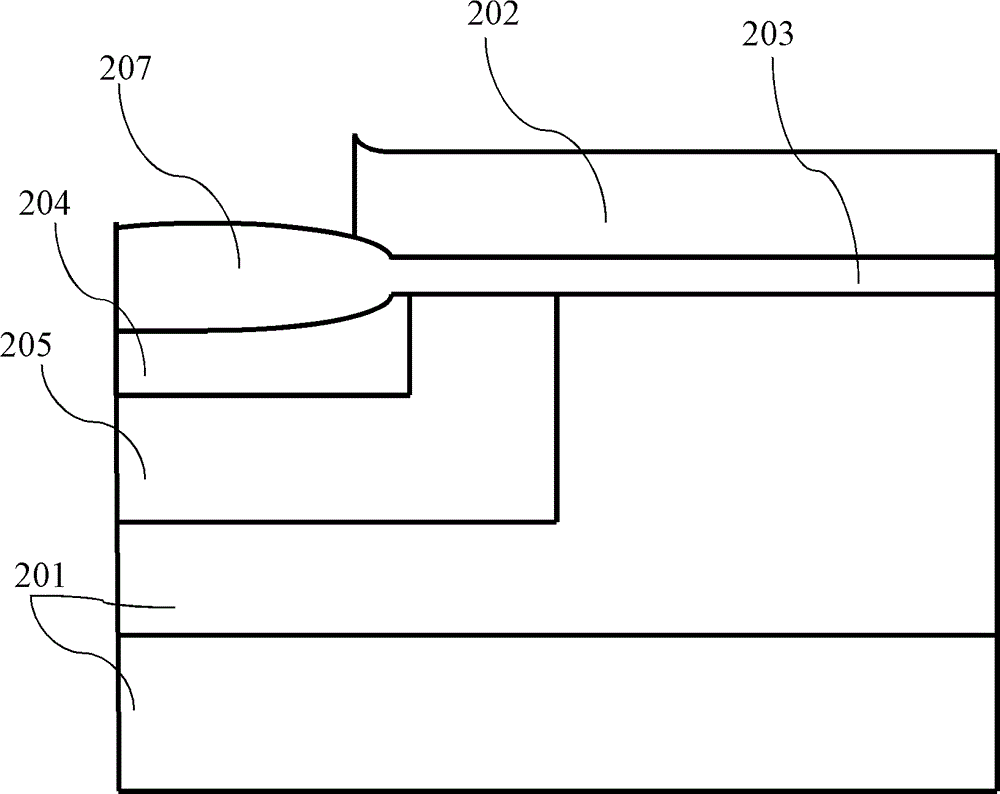

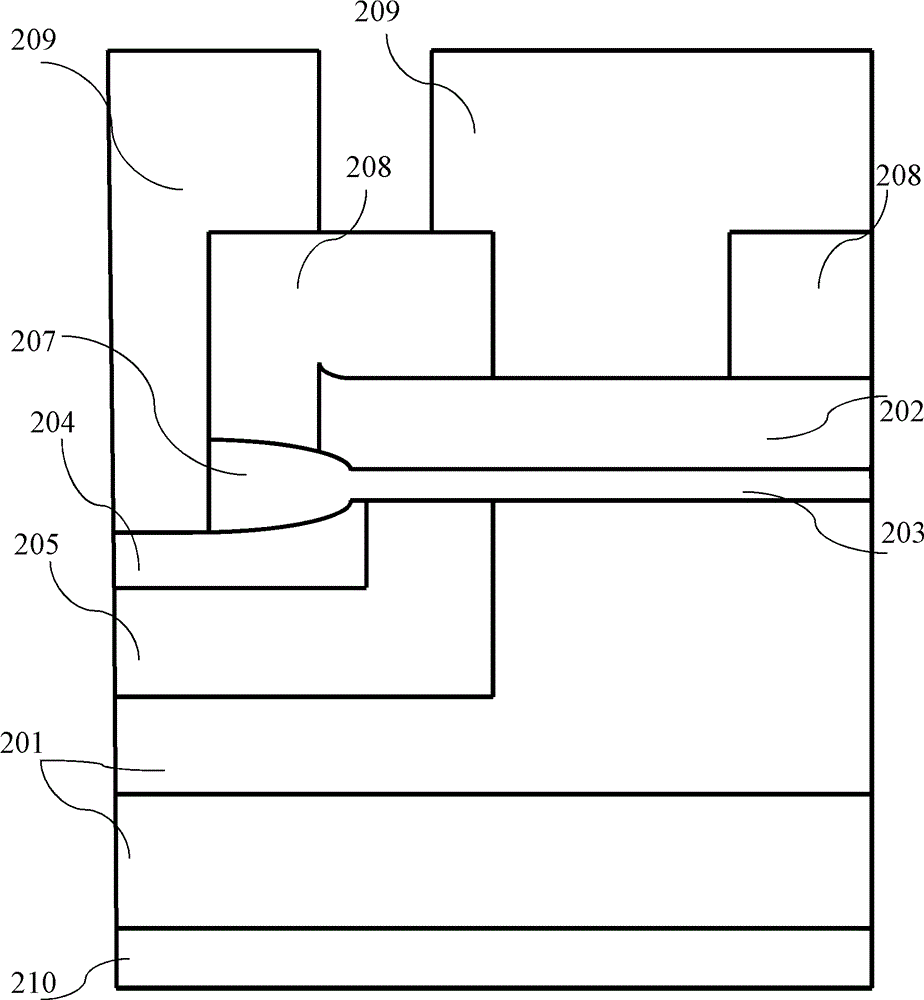

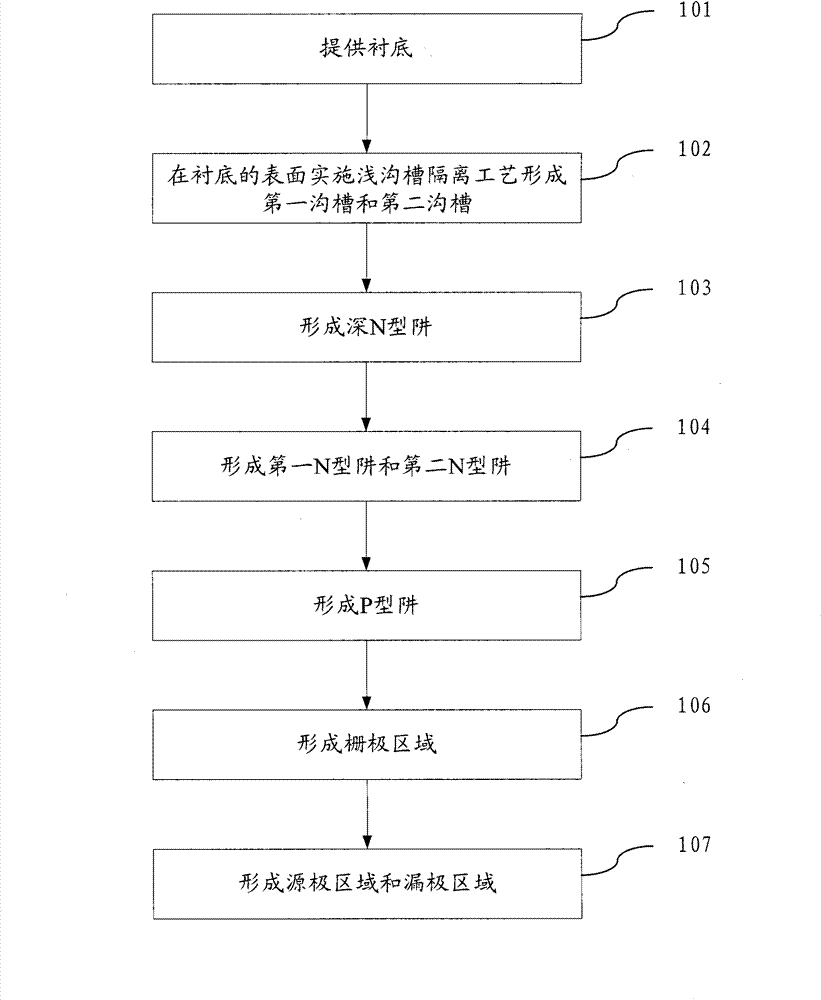

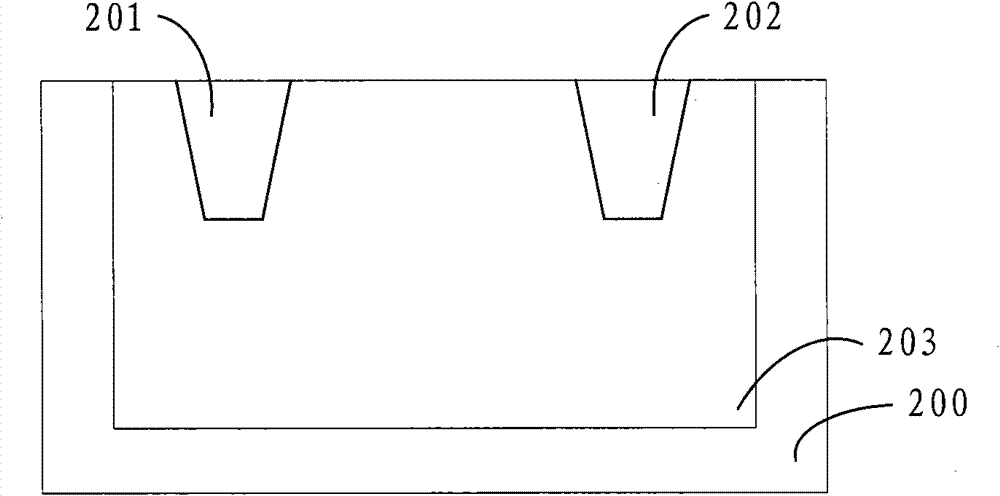

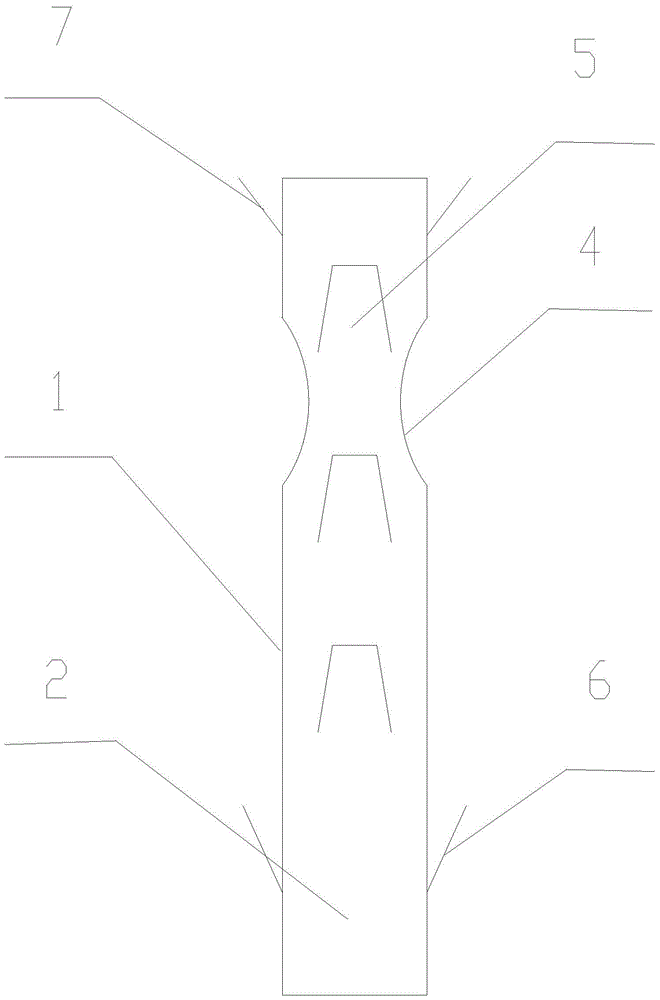

Manufacturing method of mosfet and mosfet

ActiveCN102479713BExtended service lifeIncreasing the thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETField-effect transistor

A method is provided for fabricating a Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET, 200) on a semiconductor wafer. The method includes providing a substrate containing an epitaxial layer (201), forming a gate oxide layer (203) on a surface of the epitaxial layer (201) by a first oxidization process, forming a polysilicon gate (202) on the gate oxide layer (203) within a gate region, forming a body region (205) in the epitaxial layer (201), forming a source region (204) in the body region (205) of the epitaxial layer (201), and oxidizing the source region (204) to form oxide (207) in a gap between the polysilicon gate (202) and the source region (204) on a surface of the source region (204) by a second oxidization process.

Owner:CSMC TECH FAB2 CO LTD

FPC electromagnetic shielding film and manufacturing method thereof

PendingCN109890187AConductiveAdapt to thin and light developmentMagnetic/electric field screeningVacuum evaporation coatingEngineeringMutual influence

The invention relates to a FPC electromagnetic shielding film. The FPC electromagnetic shielding film comprises a first protective layer, an adhesive layer, a metal layer, a second protective layer and a carrier film which are sequentially arranged from top to bottom, wherein the adhesive layer is used for bonding the first protective layer 1 and the metal layer, and the adhesive layer contains conductive nickel powder. The electromagnetic shielding film is attached to the surface of an FPC, can prevent mutual influence among the FPCs in an electronic product, and has high breakdown resistanceand high shielding effect on electromagnetism.

Owner:广东中晨电子科技有限公司

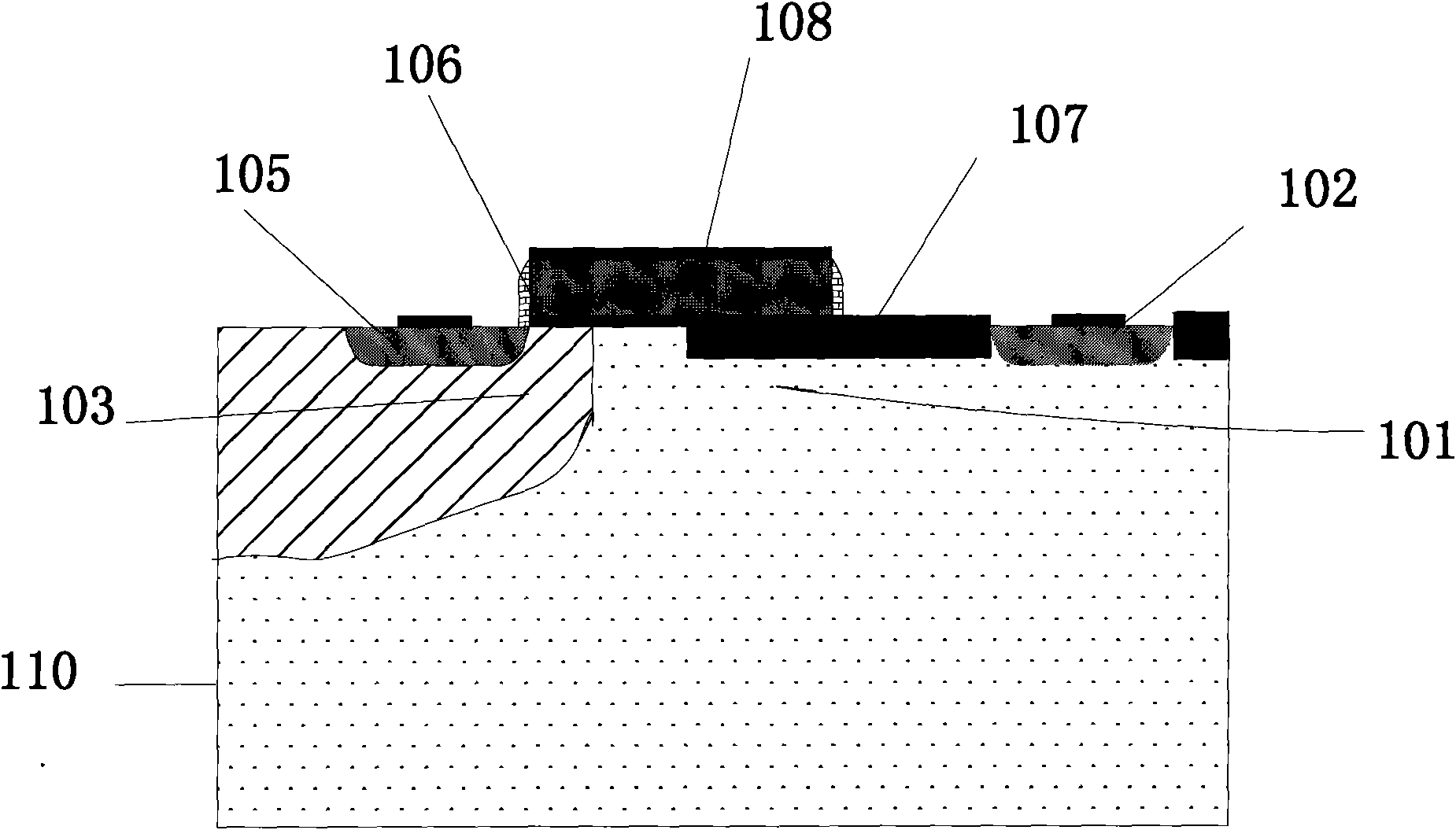

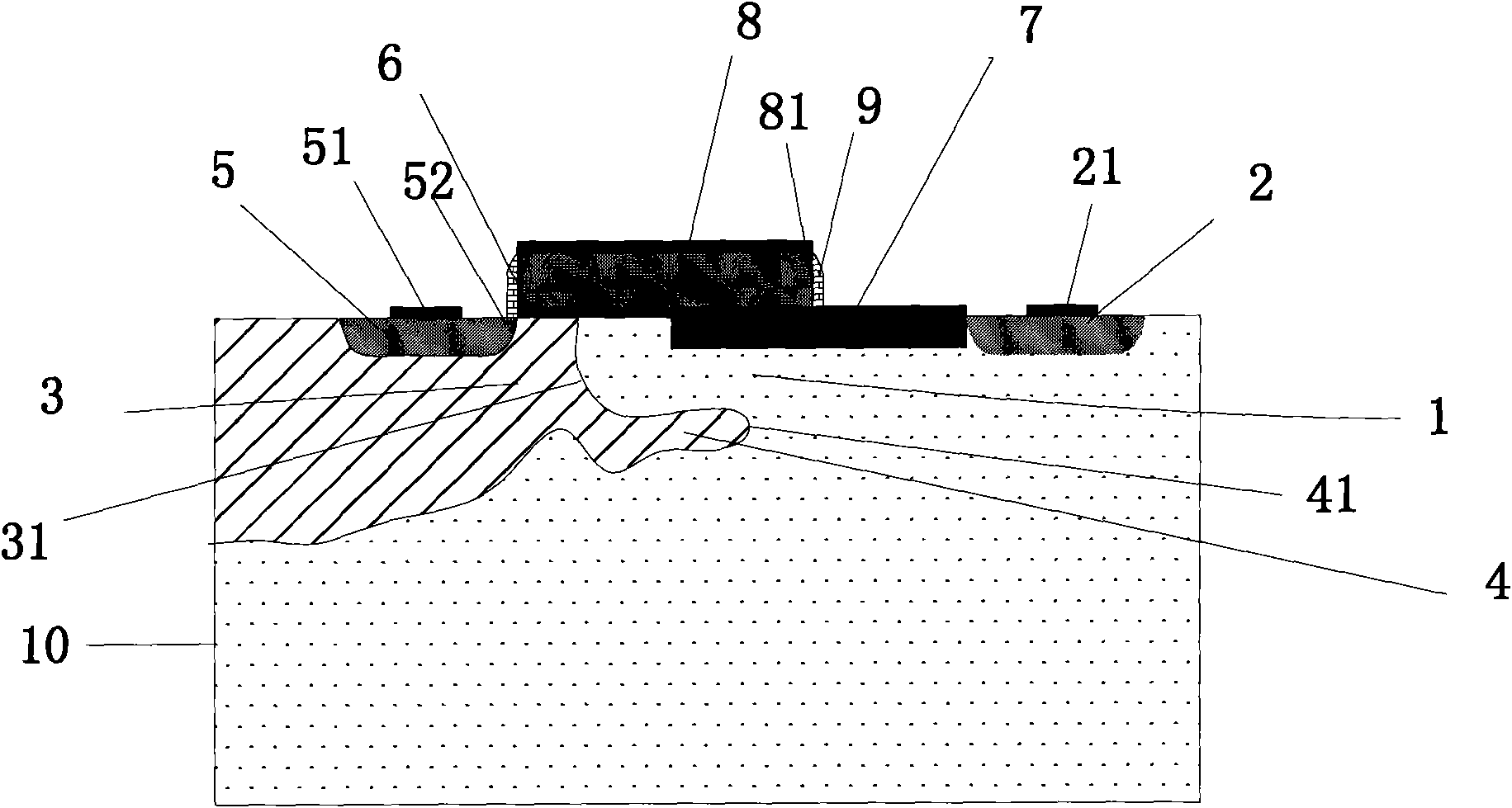

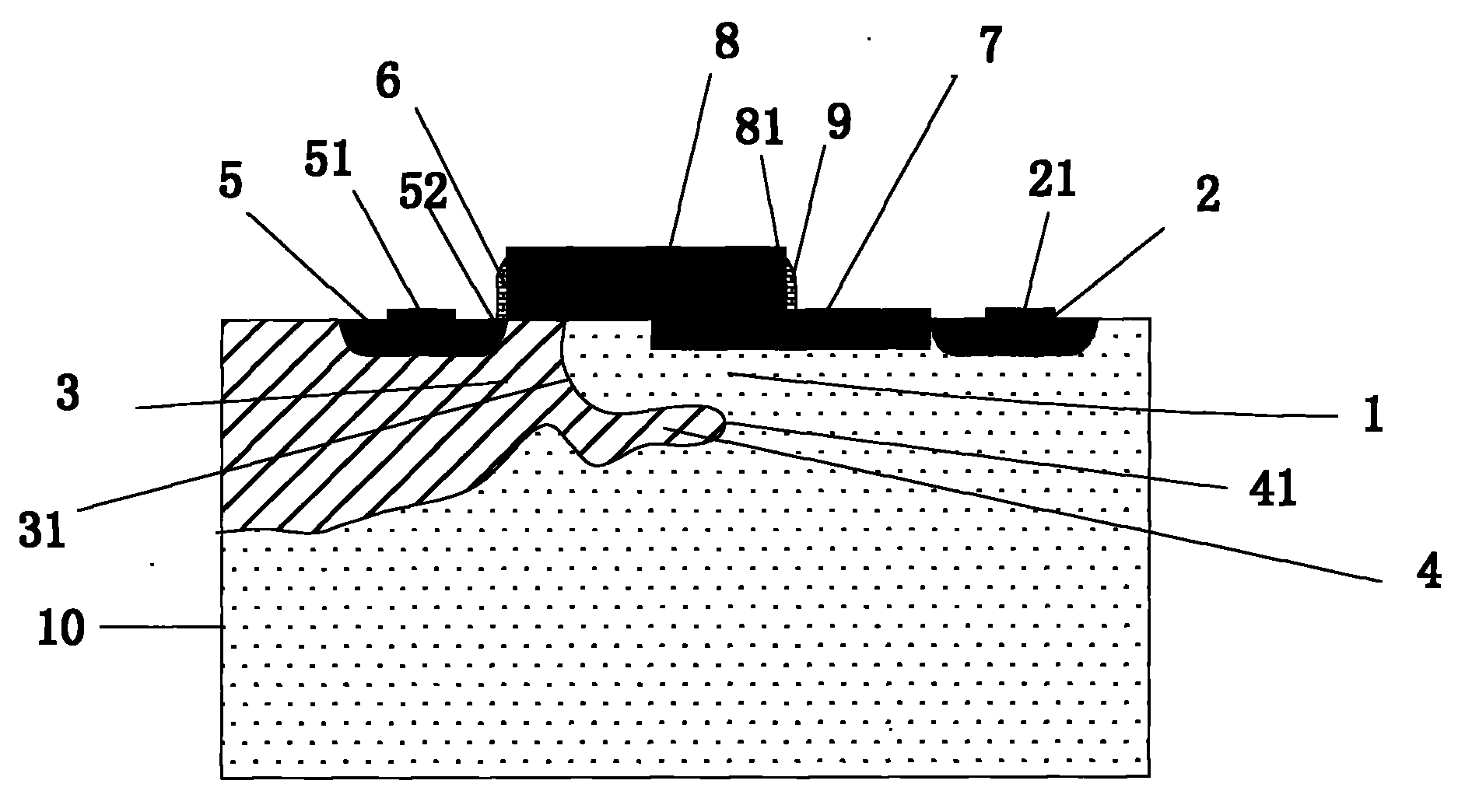

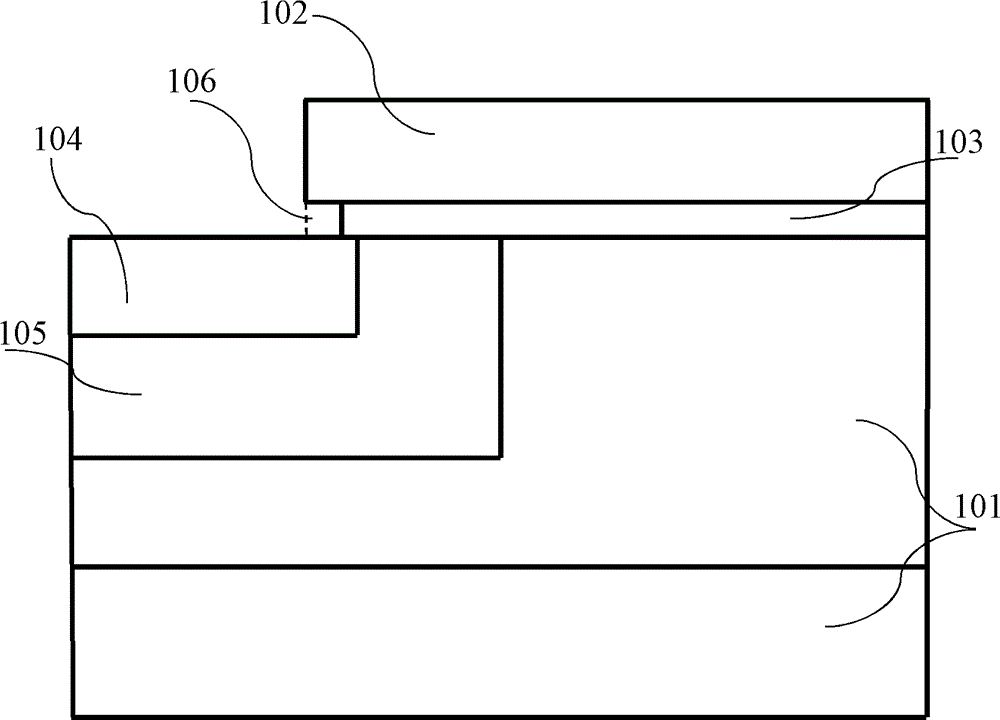

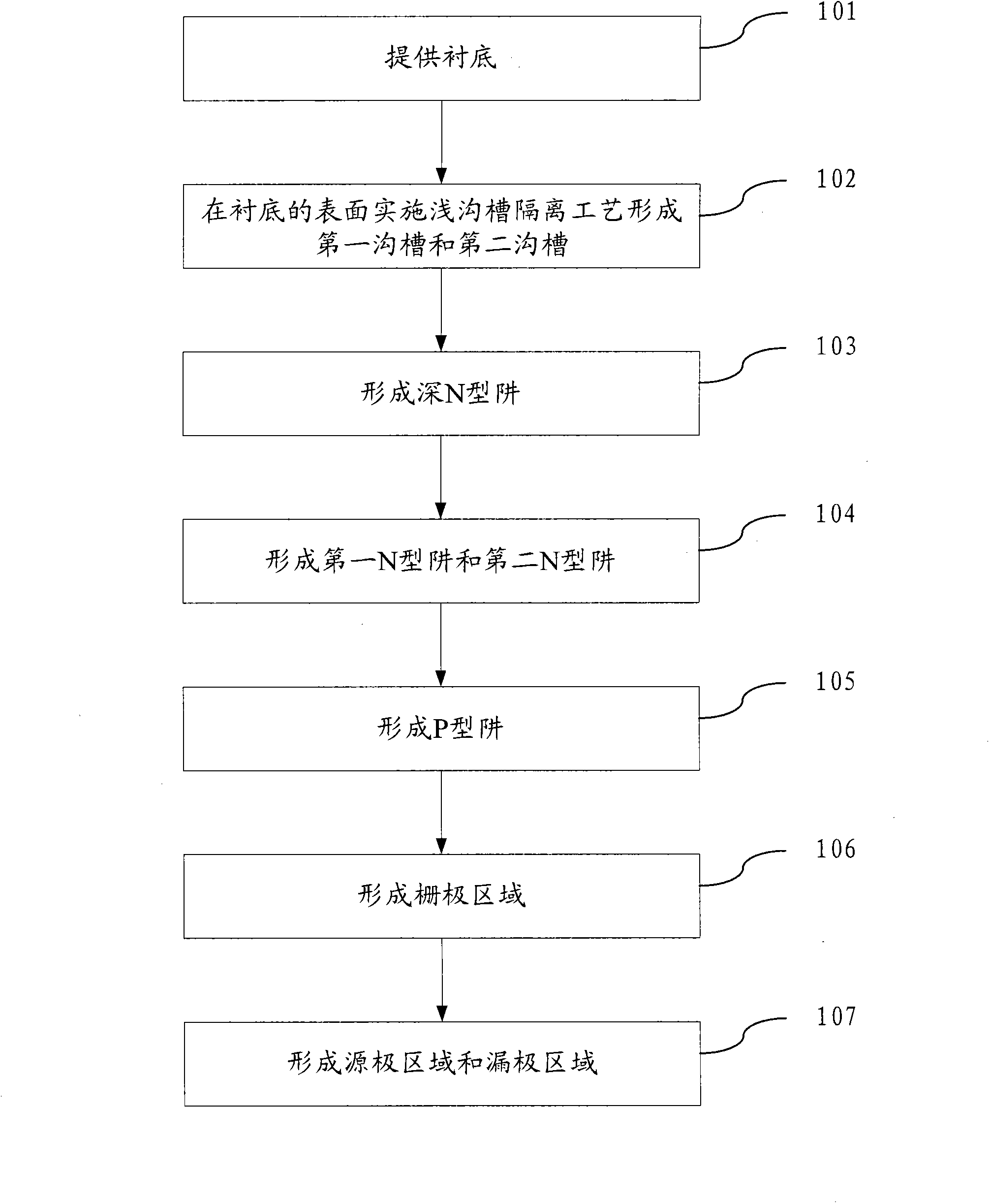

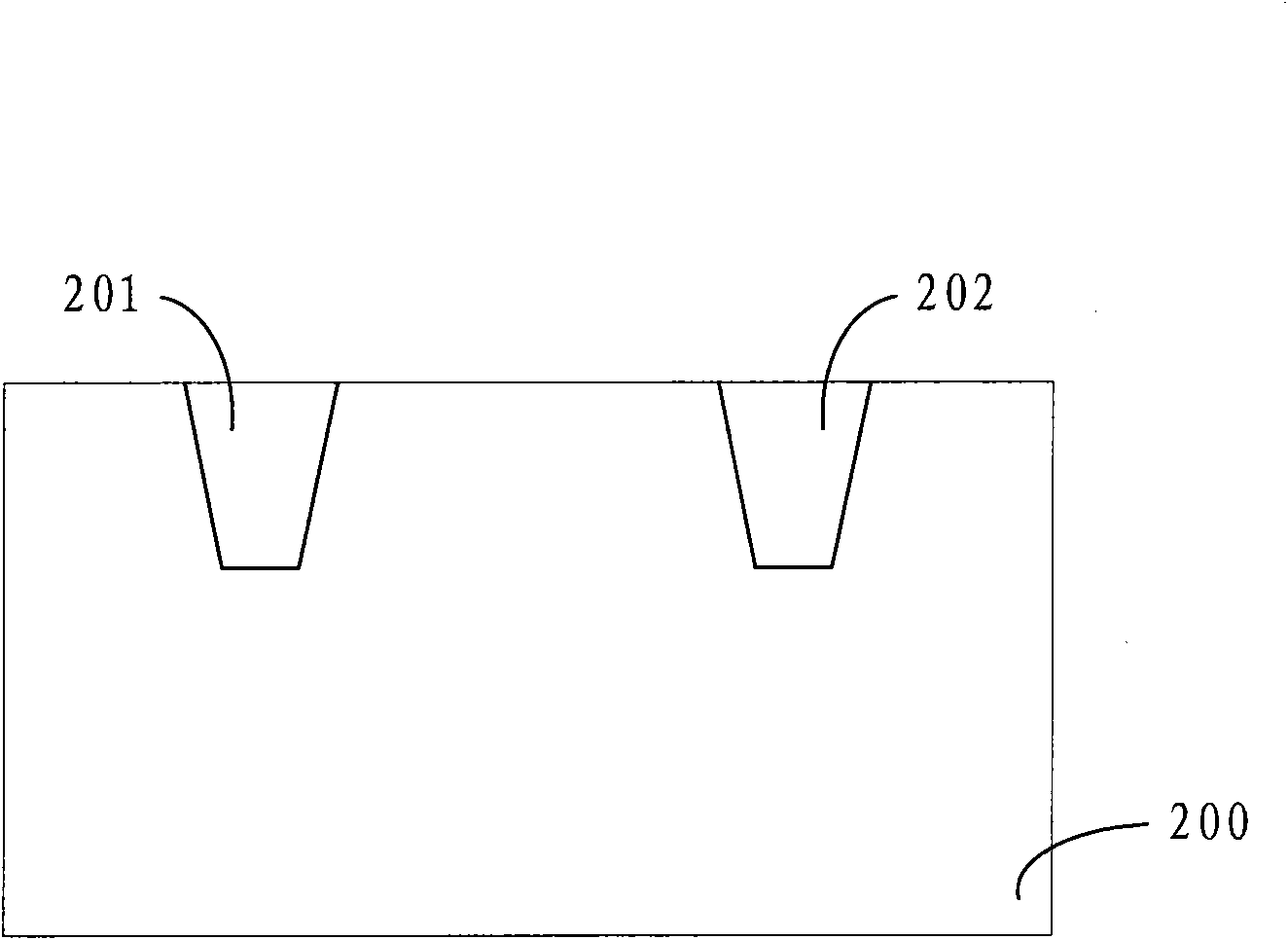

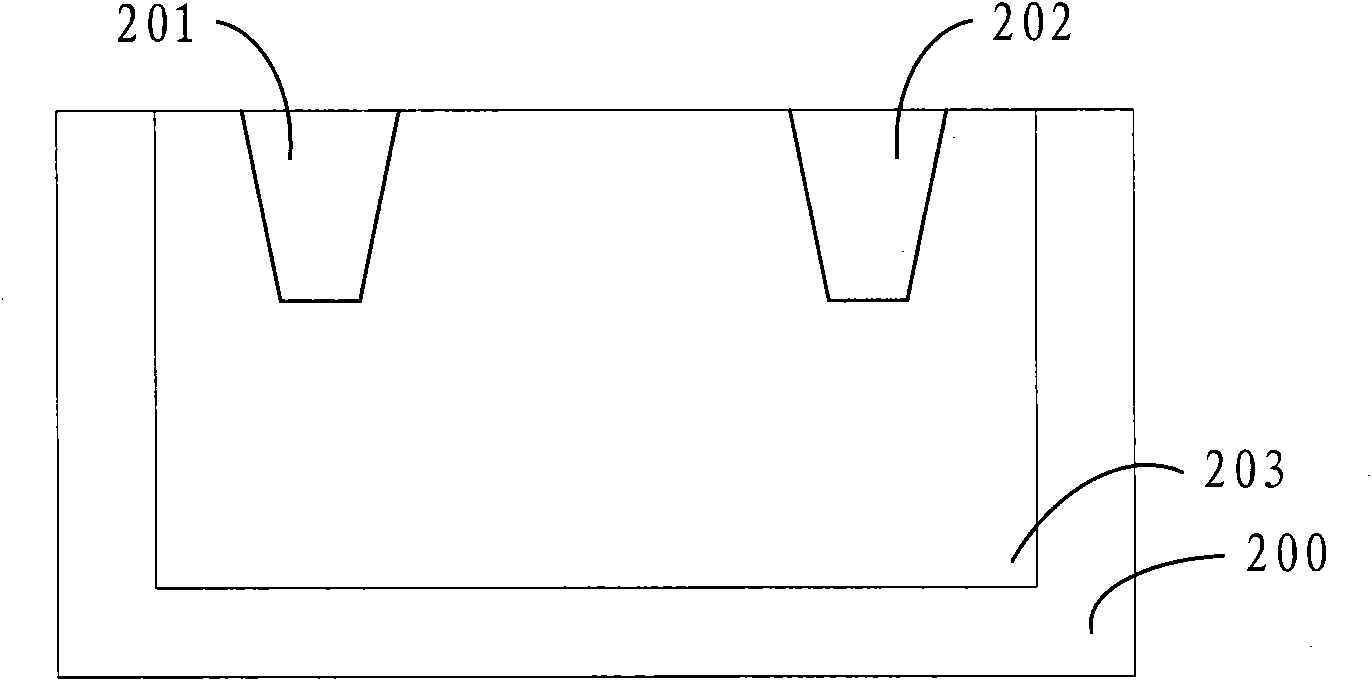

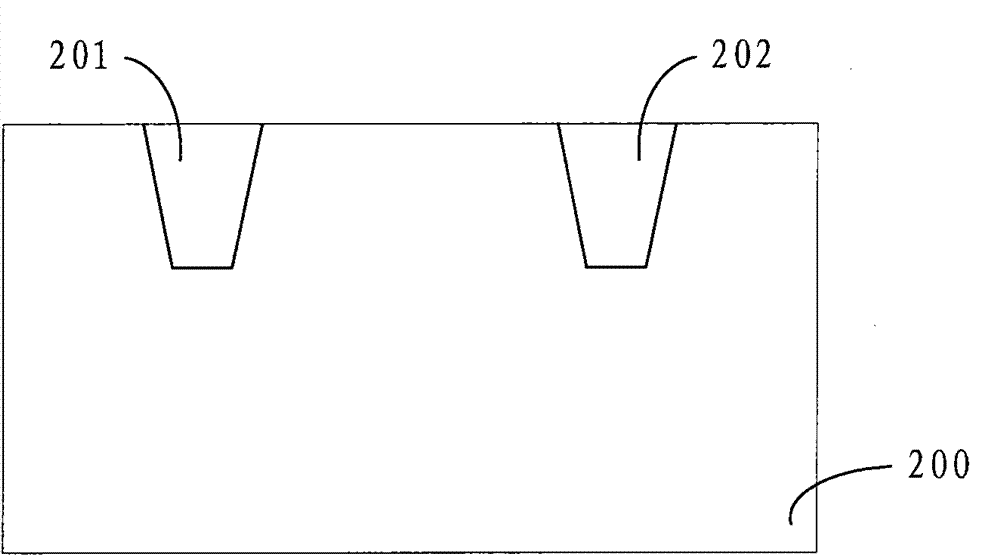

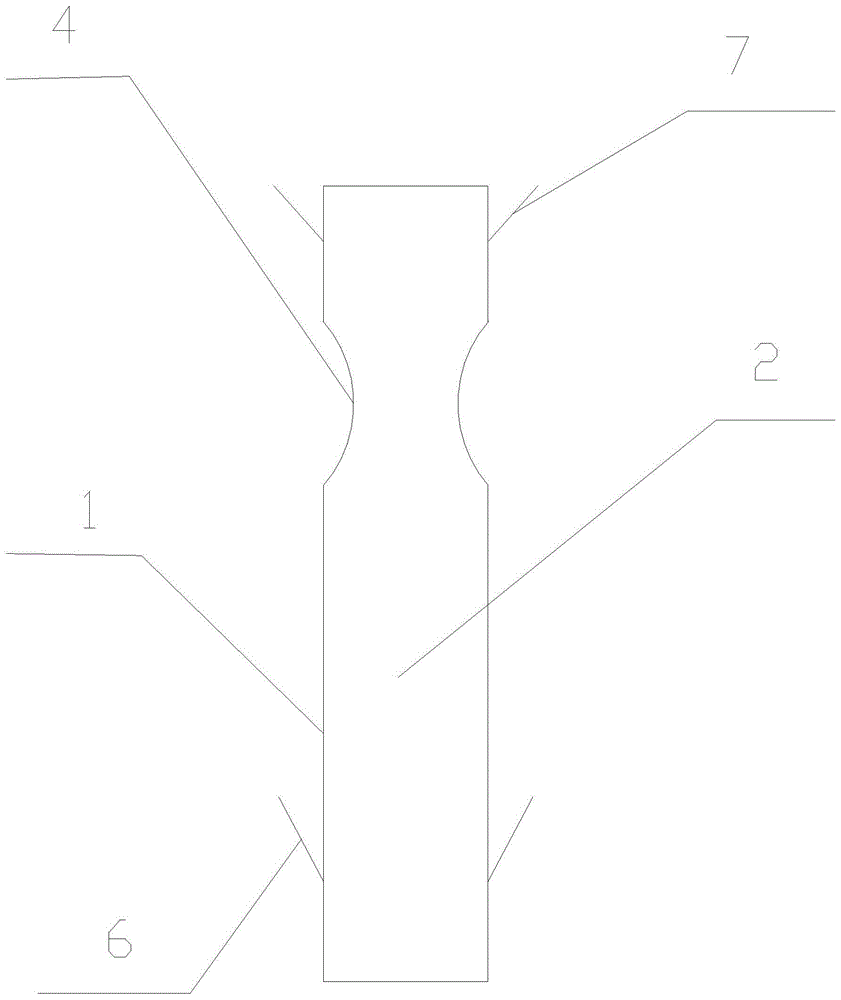

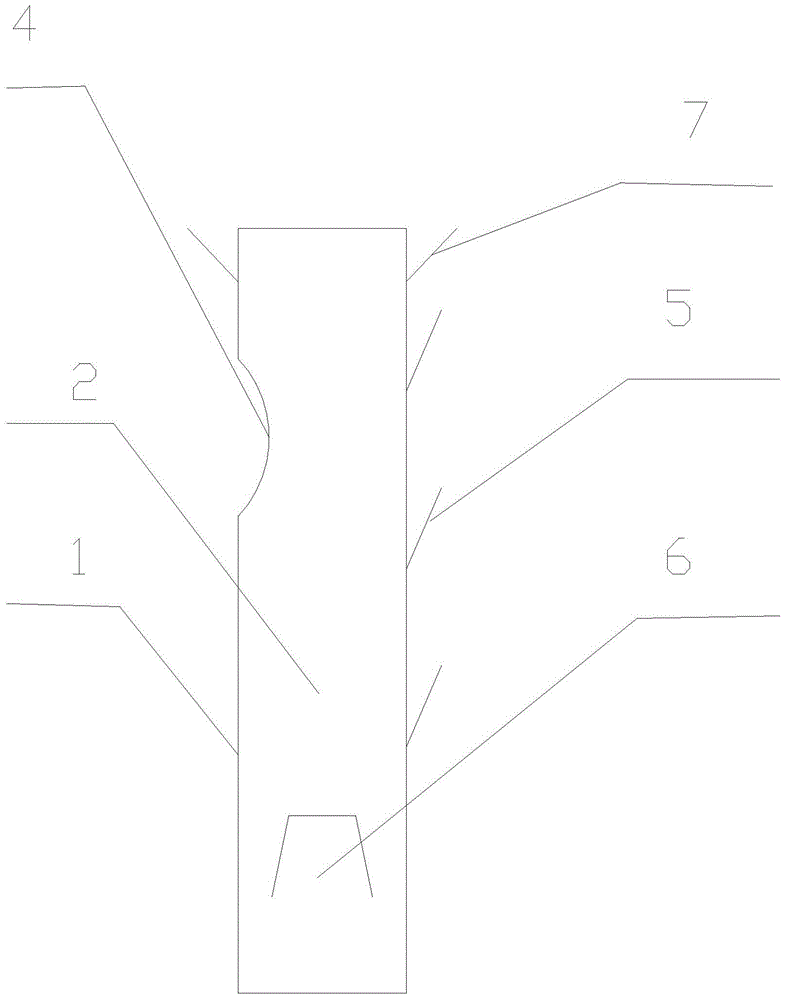

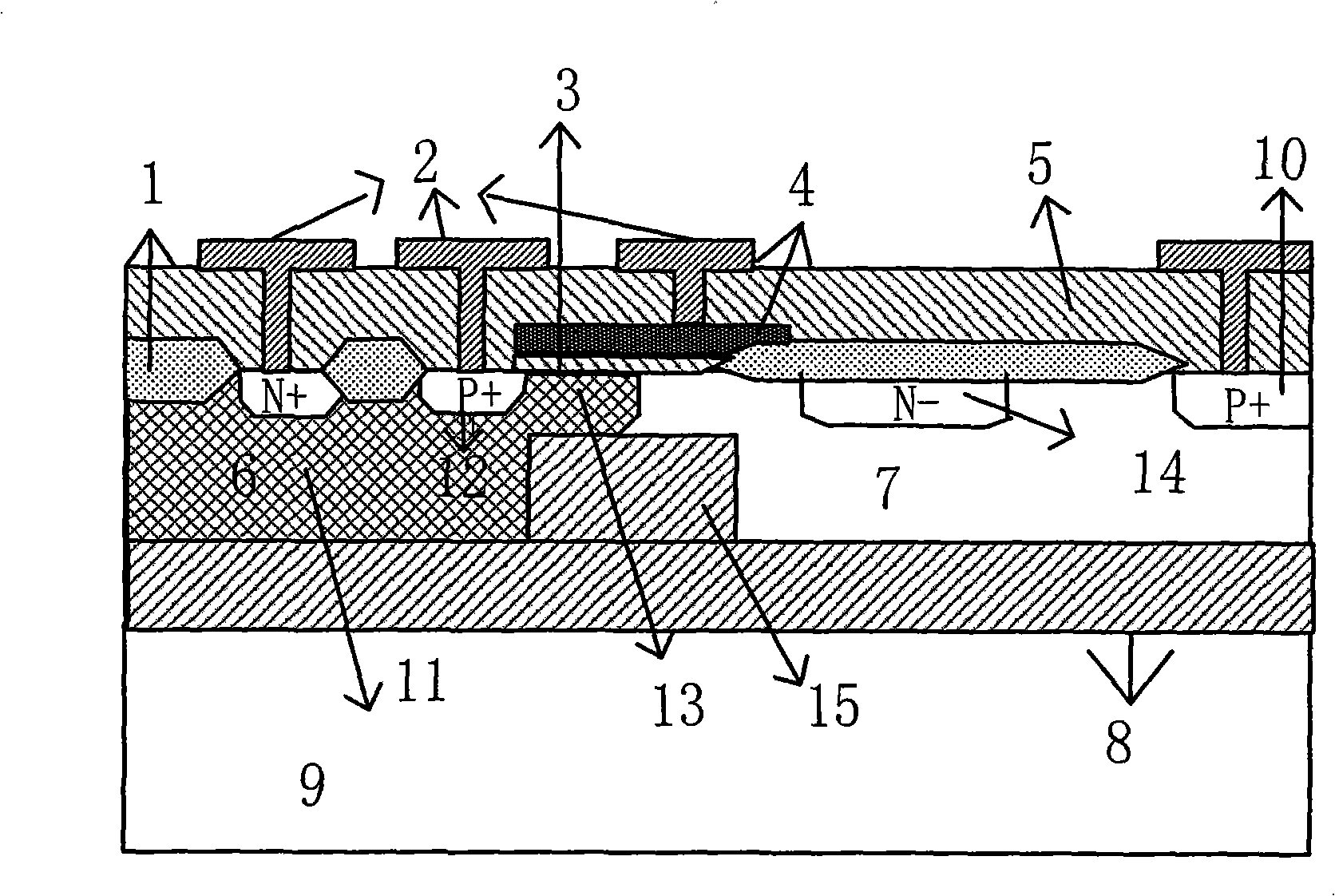

Lateral double diffusion metal oxide silicon (LDMOS) transistor and method for making same

ActiveCN102254823AExtend your lifeImprove overall lifespanSemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSDouble diffusion

The invention relates to a lateral double diffusion metal oxide silicon (LDMOS) transistor and a method for making the same. The LDMOS transistor comprises a substrate, a first groove, a second groove, a deep N-type pit, a first N-type pit, a second N-type pit, a P-type pit, a gate electrode region, a source region and a drain region. By the LDMOS transistor provided by the invention, the breakdown voltage can be effectively improved, the service of the LDMOS can be prolonged and the performance of the LDMOS can be improved under the condition of no increase of the width of the gate electroderegion; the source region and the drain region can be interchanged due to a symmetric structure to improve the performance of the transistor and make the circuit design easy; moreover, the probability of breakdown generated between the drain region and the gate region can be reduced under the condition of no increase of the size of the gate electrode region, so that the service life of the transistor is prolonged.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Lateral double diffusion metal oxide silicon (LDMOS) transistor and method for making same

ActiveCN102254823BExtend your lifeImprove overall lifespanSemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSDouble diffusion

The invention relates to a lateral double diffusion metal oxide silicon (LDMOS) transistor and a method for making the same. The LDMOS transistor comprises a substrate, a first groove, a second groove, a deep N-type pit, a first N-type pit, a second N-type pit, a P-type pit, a gate electrode region, a source region and a drain region. By the LDMOS transistor provided by the invention, the breakdown voltage can be effectively improved, the service of the LDMOS can be prolonged and the performance of the LDMOS can be improved under the condition of no increase of the width of the gate electroderegion; the source region and the drain region can be interchanged due to a symmetric structure to improve the performance of the transistor and make the circuit design easy; moreover, the probability of breakdown generated between the drain region and the gate region can be reduced under the condition of no increase of the size of the gate electrode region, so that the service life of the transistor is prolonged.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Rotating anode CT bulb with elastic metal fiber and graphene enhanced heat dissipation

ActiveCN105470079BNot easy to burstImprove thermal conductivityX-ray tube electrodesX-ray tube vessels/containerMetal fibersGraphene

The invention discloses a rotating anode CT bulb tube employing elastic metal fibers and graphene for improving heat dissipation, and belongs to the field of vacuum electronic medical devices. The bulb tube mainly comprises a tube housing, a rotating anode target connected in the tube housing, and a cathode which is located in the tube housing and is opposite to the rotating anode target. The rotating anode target is connected with the tube housing through a bearing. The tube housing comprises a cathode ceramic segment and a metal segment. The cathode ceramic segment is in a cylindrical structure with a central hole, and two ends of the cathode ceramic segment are respectively provided with an annular groove. The depth of one annular groove at one end of the interior of the metal segment is less than the depth of the annular groove at one end of the exterior of the metal segment. Moreover, an inner end face of the annular groove at the end of the exterior of the metal segment is lower than an outer end face. Nano-level graphene powder is disposed in a bearing ball cavity, and two ends of the bearing ball cavity are provided with stopping pieces. The elastic metal fibers are disposed between the surface of the rotating anode target and the opposite surface of the tube housing, and contact with the tube housing and a target head.

Owner:电科睿视技术(北京)有限公司

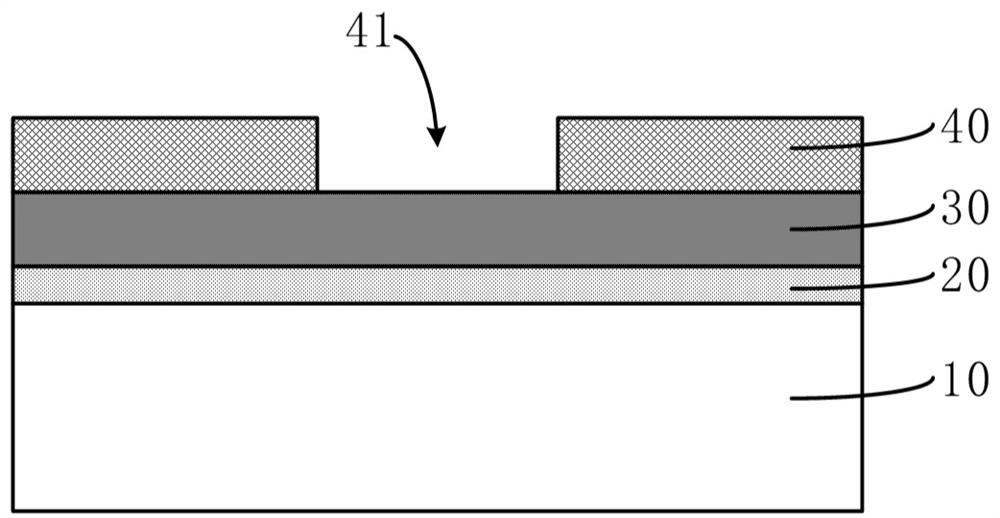

Preparation method of semiconductor device

ActiveCN114551224BImprove electrical performanceAvoid etch damageSemiconductor/solid-state device manufacturingCleaning using liquidsDevice materialPhotoresist

The present invention provides a method for preparing a semiconductor device, comprising: providing a substrate, on which a first dielectric layer, a second dielectric layer and a patterned photoresist layer are sequentially formed, and the patterned photoresist layer is formed in sequence on the substrate. The resist layer has an opening; a dry etching process is used to etch the second dielectric layer along the opening to reveal the surface of the first dielectric layer, and the opening extends to the surface of the first dielectric layer surface; continuing to etch the first dielectric layer along the opening by a wet etching process to reveal the surface of the substrate, and the opening extends to the surface of the substrate; and, removing the patterning A field oxide layer is formed on the surface of the substrate at the bottom of the opening; the invention improves the smoothness of the interface between the field oxide layer and the substrate, improves the avalanche resistance of the device, thereby improving the the electrical properties of semiconductor devices.

Owner:GUANGZHOU CANSEMI TECH INC

Impact-resistant chip resistor and manufacturing method of chip resistor

ActiveCN114334321AExtended service lifeStrong antioxidantResistor manufactureResistor detailsWaferingEngineering

The invention discloses an impact-resistant chip resistor and a manufacturing method thereof, and relates to the technical field of resistors, the impact-resistant chip resistor comprises a resistor body, the resistor body further comprises a substrate mounted at the bottom, the top of the substrate is fixedly connected with an impedance element, the top of the impedance element is provided with a base layer sealing layer, and the top of the base layer sealing layer is fixedly connected with the substrate. The top of the base sealing layer is fixedly connected with the second sealing layer, one side of the substrate is provided with the inner end face, the outer surface of the inner end face is provided with the middle end face, the outer surface of the middle end face is fixedly connected with the outer end face, the top of the substrate is provided with the first conductive plate, and one side of the first conductive plate is fixedly connected with the ceramic tube. One end of the ceramic tube is provided with a second conductive plate, the outer surface of the ceramic tube is sleeved with a nickel wire, and the substrate is also provided with a conductive plate I. The chip resistor has the advantages of low manufacturing cost, long service life, high temperature resistance, oxidation resistance and good corrosion resistance, and the impact resistance, safety and stability of the chip resistor are improved.

Owner:深圳市宏远立新电子有限公司

An electrode cover and a detachable xenon headlamp

InactiveCN103545626BSimple structureEasy to assembleGas discharge lampsMultiple conductors connectorElectrode insertionEngineering

The invention discloses an electrode sleeve, which includes a conductive sleeve body, an electrode cavity that can be inserted into an electrode is provided in the sleeve body, an electrode insertion port is provided on the upper part of the electrode cavity, and an electrode cavity is provided in the electrode cavity. The side wall is provided with a conductive first elastic extrusion part that is in contact with the electrode, and the outer side of the sleeve is provided with a conductive second elastic extrusion part that is in contact with the outer electrode. The lower part of the sleeve body is provided with a stop card that can be engaged with the external bayonet. The invention aims to provide an electrode cover with excellent contact with the output electrode and input electrode and a good fixation, and a detachable xenon headlamp using the electrode cover with the advantages of anti-breakdown, easy disassembly and installation, safety and stability.

Owner:GUANGZHOU OPLAS ELECTRICAL CO LTD

Electrical system of polycrystalline silicon rod reduction furnace and its starting method

InactiveCN104003394BReduce the possibility of breakdownLow costSilicon compoundsElectricityMetallurgy

The invention discloses an electrical system of a reduction furnace with polycrystalline silicon rods and a starting method of the reduction furnace with the polycrystalline silicon rods, and particularly relates to the starting method of the reduction furnace with the twenty-four pairs of polycrystalline silicon rods. The electrical system comprises the twenty-four pairs of polycrystalline silicon rods, wherein the four pairs of polycrystalline silicon rods are distributed on an inner ring, the eight pairs of polycrystalline silicon rods are distributed on a middle ring, and the twelve pairs of polycrystalline silicon rods are distributed on an outer ring; the twenty-four pairs of polycrystalline silicon rods are all connected with a power-adjusting-cabinet power source, the eight pairs of polycrystalline silicon rods distributed on the middle ring are further connected with a high-voltage starting power source through a middle-ring isolating switch, the four pairs of polycrystalline silicon rods distributed on the inner ring are further connected with four sets of thyristor modules, and each pair of polycrystalline silicon rods on the inner ring corresponds to a set of antiparallel thyristors. According to the method, after the middle ring is broken down through a high voltage, electricity is completely supplied by a normal power source, breakdown is conducted on the inner ring in an alternating mode under the baking action of the middle ring, and the outer ring is directly started under the baking action of the inner ring and the middle ring after the inner ring is broken down.

Owner:SHAANXI TIANHONG SILICON IND

Dispersing agent for wet electroceramic body connecting process and wet body-connecting method

Owner:湖南华联火炬电瓷电器有限公司

High voltage P type SOI MOS transistor

InactiveCN101488523BImprove breakdown voltageHigh charge densitySemiconductor devicesP type siliconSource area

Owner:SOUTHEAST UNIV

Composite material j-shaped vertical wall positioning overall forming tooling and forming method

ActiveCN105346102BPrecise positioningGuaranteed positioningStructural engineeringCarbon fiber composite

Owner:SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com