Rotating anode CT bulb tube employing elastic metal fibers and graphene for improving heat dissipation

A rotating anode, elastic metal technology, applied in the direction of X-ray tube electrodes, X-ray tube parts, X-ray tube shells/containers, etc. Heat take away and other problems, to achieve the effect of high reliability, good air tightness, and increase the area of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

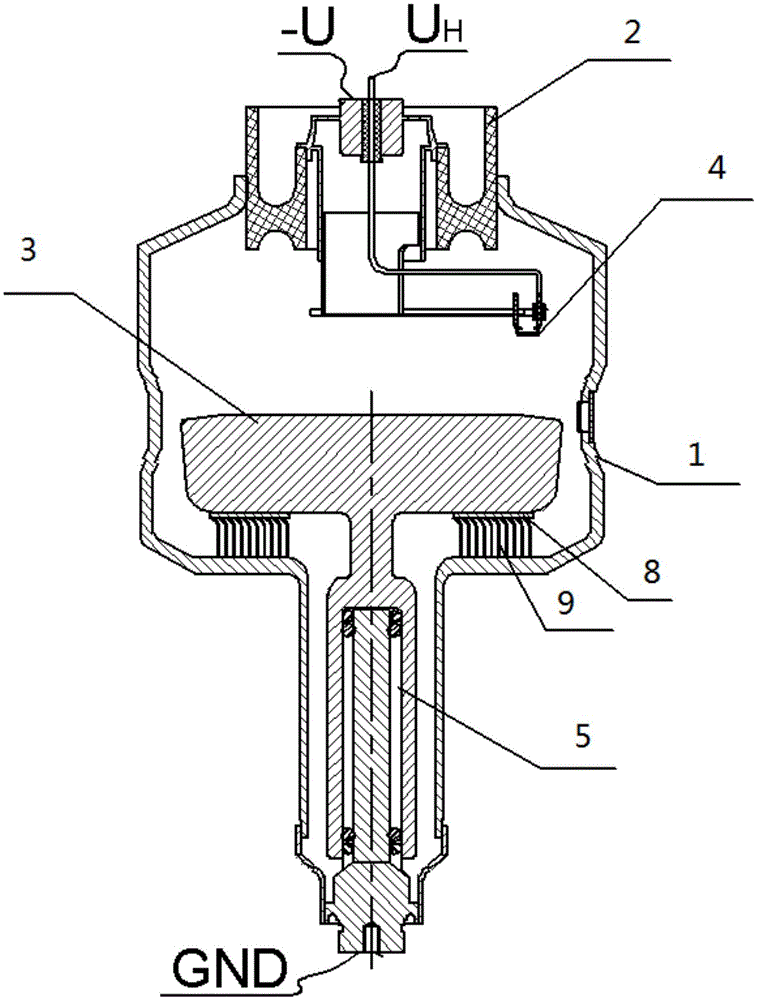

[0030] A rotating anode CT bulb that uses elastic metal fibers and graphene to enhance heat dissipation. The structural schematic diagram of the CT bulb is shown in figure 1 As shown, it mainly includes a tube shell, a rotating anode target 3 connected to the tube shell, and a cathode 4 located in the tube shell and corresponding to the position of the rotating anode target 3; wherein, the rotating anode target 3 passes through The bearing 5 is connected with the shell;

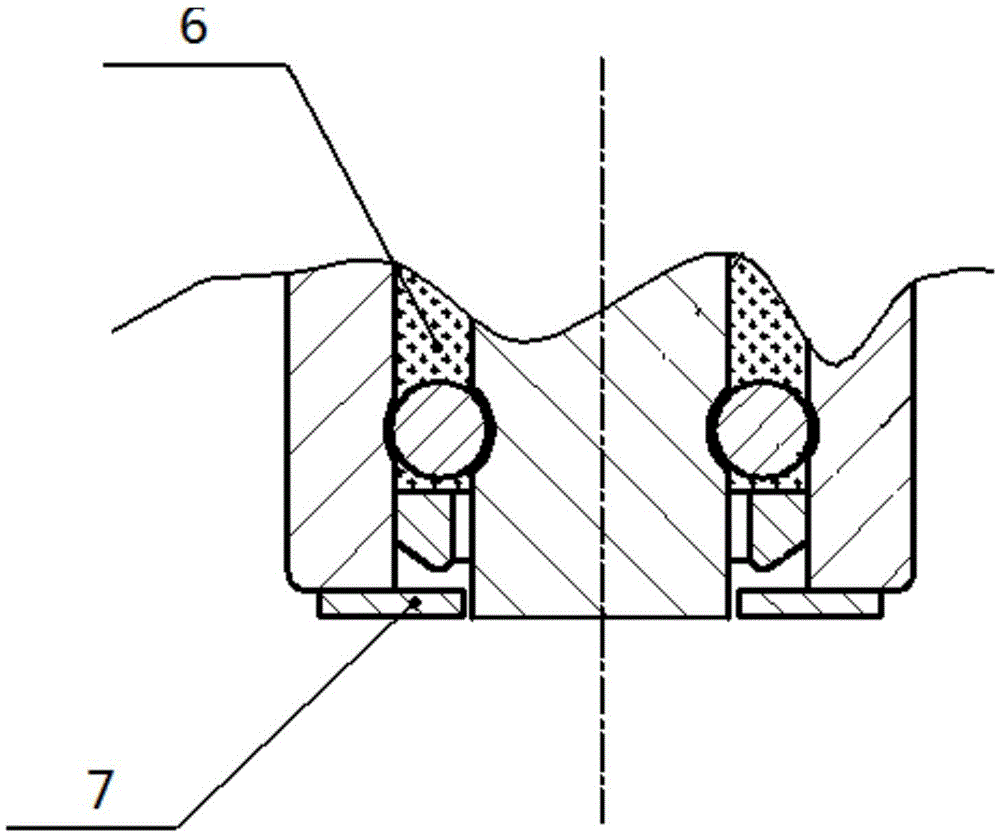

[0031] The casing includes a cathode ceramic section 2 and a metal section 1, wherein the cathode ceramic section 2 is a cylindrical structure with a central hole, mainly for insulation, and its two ends are respectively processed with annular grooves, which are located in the metal section 1 The groove depth of the annular groove at one end is smaller than the groove depth of the annular groove at one end outside the metal segment 1, and the end face inside the ring groove at one end outside the metal segmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com