An epitaxial wafer and a growth method for improving the antistatic ability of a gallium nitride-based LED light emitting diode

A light-emitting diode, gallium nitride-based technology, applied in circuits, electrical components, semiconductor devices, etc., can solve surface defects, affect chip anti-static problems, etc., and achieve the effect of optimizing design, improving anti-static ability, and uniform density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

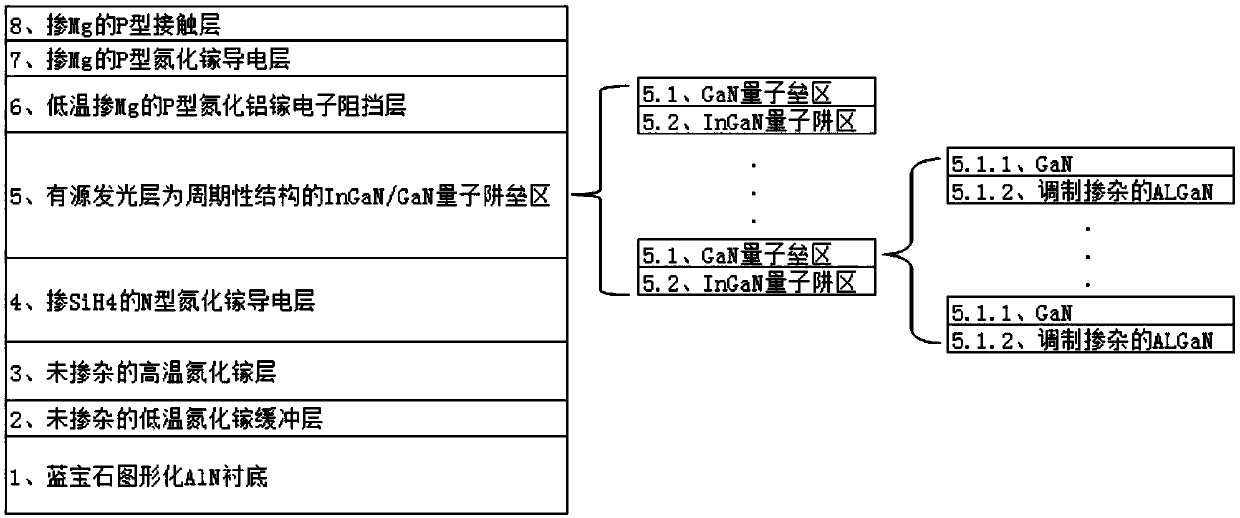

[0042] An epitaxial wafer growth method for improving the antistatic ability of gallium nitride-based LED light-emitting diodes, comprising the following process steps:

[0043] Step 1: After cleaning the sapphire patterned ALN substrate, put it on the graphite disk in the MOCVD chamber, and bake it at about 1040°C for 11 minutes;

[0044] Step 2: Cool down to 525°C and grow a low-temperature GaN layer with a thickness of 27nm under a pressure of 500mbar;

[0045] Step 3: Raise the temperature to 1110°C and grow a high-temperature GaN layer with a thickness of 2200nm under a pressure of 750mbar;

[0046] Step 4: growing a SiH4-doped n-type high-temperature GaN layer with a thickness of 2700 nm at a temperature of 1065° C. and a pressure of 600 mbar;

[0047] Step 5: At a temperature of 825°C and a pressure of 300mbar, a layer of 2nm GaN is grown, and then a layer of 2nm modulated doped AlGaN is grown, and the two are used as a superlattice unit structure, which is grown alter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com