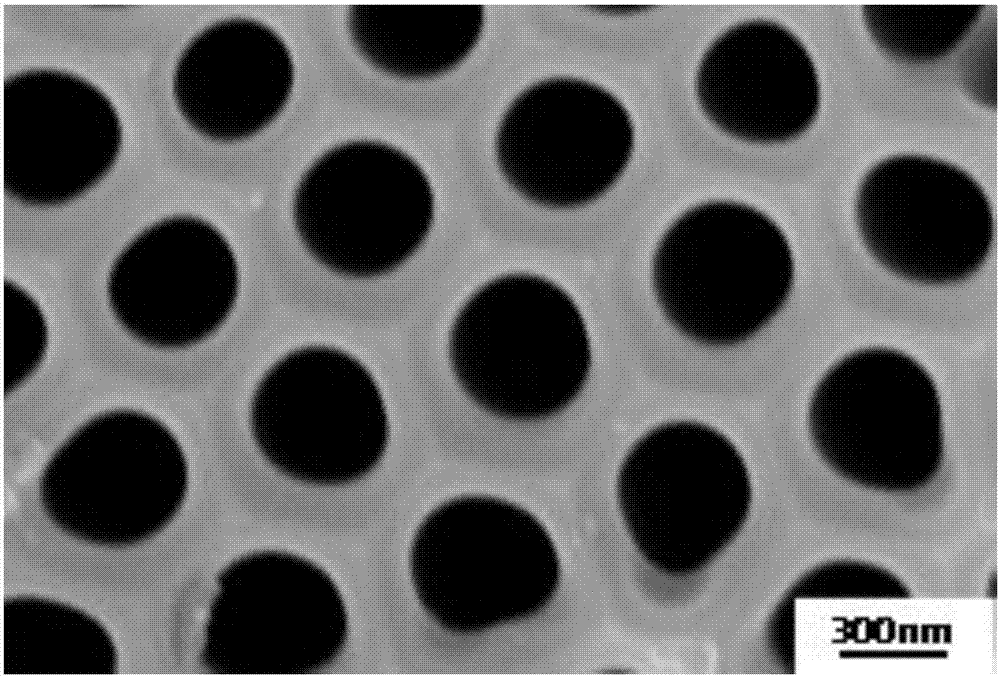

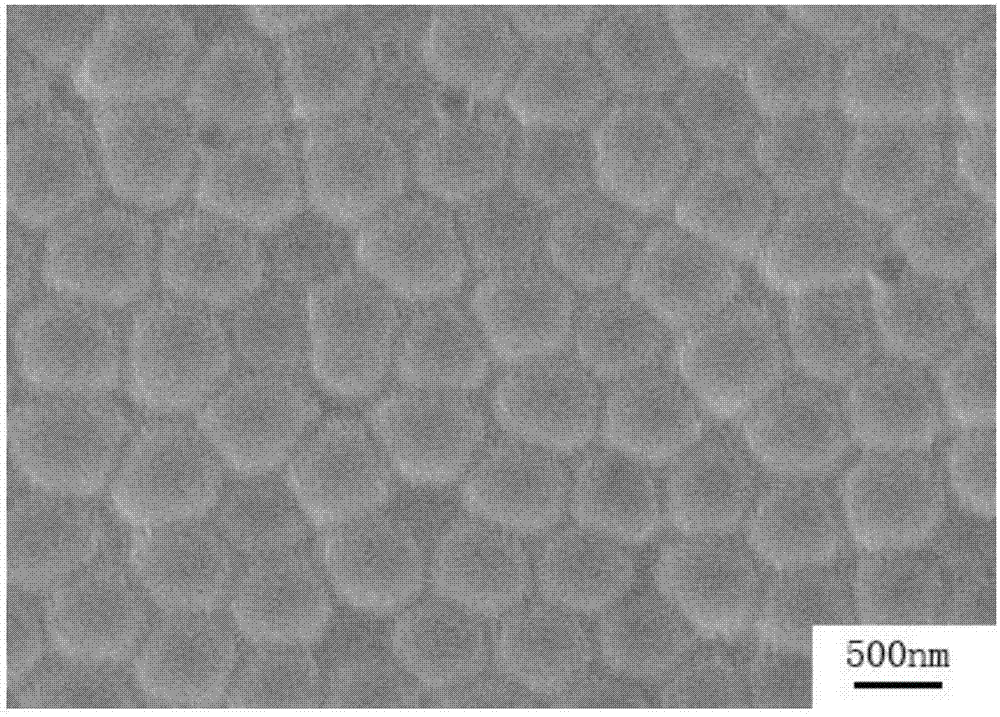

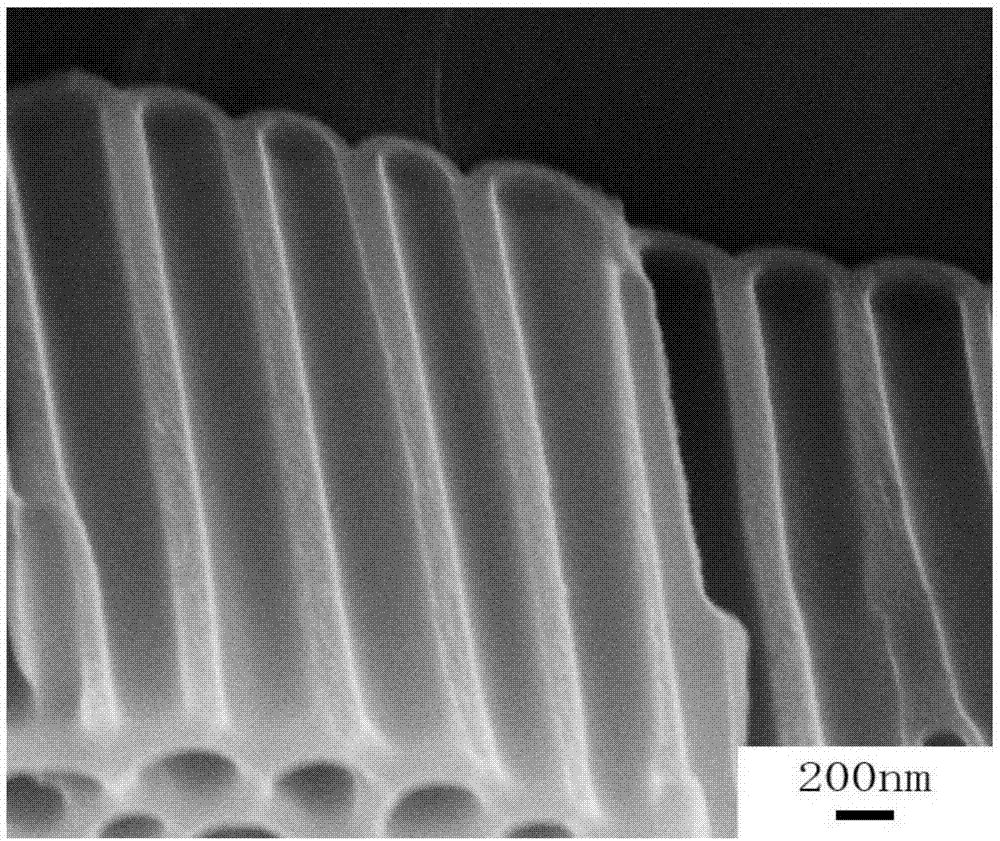

Method for obtaining large-hole-diameter double-through-hole AAO membrane

A large-pore, single-pass technology, used in electrolytic coatings, surface reaction electrolytic coatings, anodizing and other directions, can solve problems such as easy to cause harm, fast reaction rate, AAO membrane corrosion, etc. order, the effect of ensuring order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Step 1. Pretreatment of aluminum foil

[0047] The preprocessing process is as follows:

[0048] Step1.1: Anneal the aluminum foil with a purity of 99.999% at 500°C for more than 2 hours to eliminate the internal stress generated during the processing of the aluminum foil, reduce microscopic defects such as grain boundaries, and increase the grain size.

[0049] Step1.2: Place the annealed aluminum foil in acetone, absolute ethanol, and distilled water in sequence for ultrasonic cleaning to remove surface contamination.

[0050] Step1.3: Use the cleaned aluminum foil as the anode, and the platinum mesh as the cathode, in a mixed solution of perchloric acid and ethanol (the content of perchloric acid is 3.5M, and the content of absolute ethanol is 14M), the aluminum foil is Electrochemical polishing eliminates mechanical damage on the surface of the aluminum foil and obtains a mirror-smooth and flat aluminum foil.

[0051] Step 2. Prepare a large-aperture single-throug...

Embodiment 2

[0070] Step 1. Pretreatment of aluminum foil

[0071] The pretreatment process is the same as that in Example 1.

[0072] Step 2. Prepare a large-aperture single-through-hole AAO membrane with an aluminum substrate and a barrier layer by secondary anodic oxidation

[0073] The process of preparation is as follows:

[0074] Step2.1: Prepare an anodic oxidation electrolyte, which is a mixed solution of phosphoric acid and sodium oxalate, wherein the content of phosphoric acid is 0.2M, and the content of sodium oxalate is 0.03M.

[0075] Step2.2: Use the pretreated aluminum foil as the anode, immerse in the anodic oxidation electrolyte prepared in Step2.1, use the platinum mesh as the cathode, and perform the first anodic oxidation, the oxidation voltage is 150V, and the oxidation temperature is -1 ℃, the oxidation time is 3h.

[0076] Step2.3: Remove the aluminum oxide layer obtained by the first oxidation in a mixed solution of chromium trioxide and phosphoric acid (the cont...

Embodiment 3

[0087] Step 1. Pretreatment of aluminum foil

[0088] The pretreatment process is the same as that in Example 1.

[0089] Step 2. Prepare a large-aperture single-through-hole AAO membrane with an aluminum substrate and a barrier layer by secondary anodic oxidation

[0090] The process of preparation is as follows:

[0091] Step2.1: Prepare an anodic oxidation electrolyte, which is a mixed solution of phosphoric acid and sodium oxalate, wherein the content of phosphoric acid is 0.05M, and the content of sodium oxalate is 0.02M.

[0092] Step2.2: Use the pretreated aluminum foil as the anode, immerse in the anodic oxidation electrolyte prepared in Step2.1, use the platinum mesh as the cathode, and perform the first anodic oxidation, the oxidation voltage is 200V, and the oxidation temperature is -3 ℃, the oxidation time is 2h.

[0093] Step2.3: Remove the aluminum oxide layer obtained by the first oxidation in a mixed solution of chromium trioxide and phosphoric acid (the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com