Preparation method of semiconductor device

A semiconductor and device technology, which is applied in the field of semiconductor device preparation, can solve the problems of increasing on-resistance, increasing device size, and low doping concentration, and achieves the effect of improving electrical performance, reducing possibility, and not increasing electric field intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

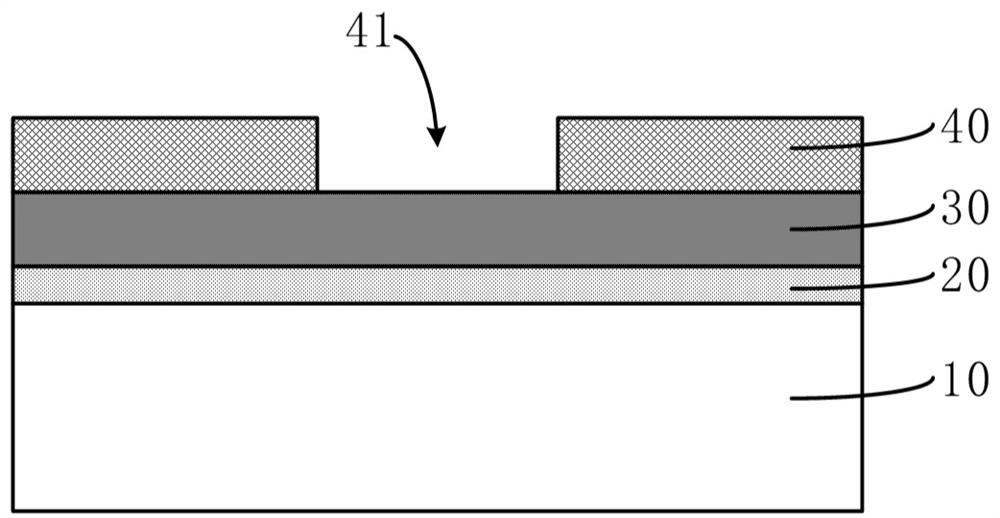

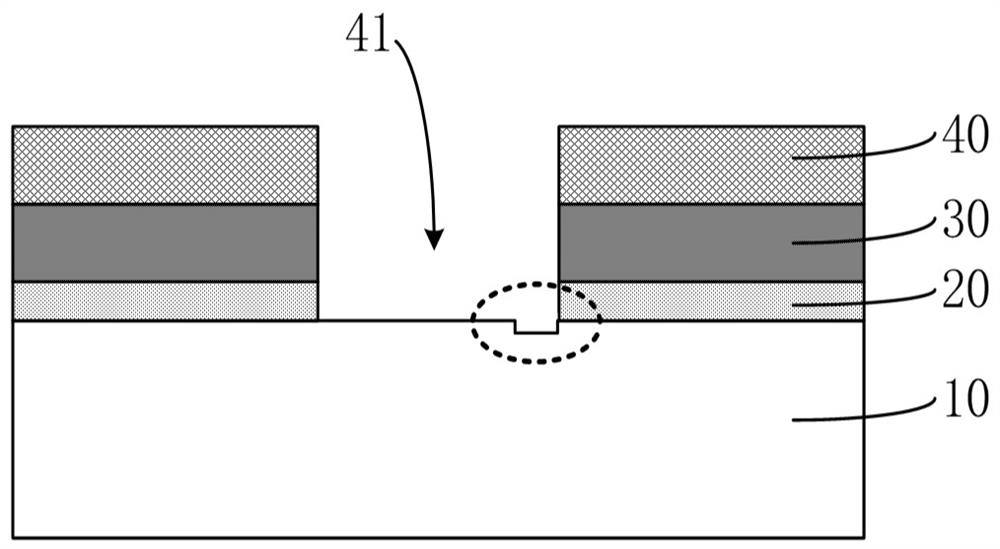

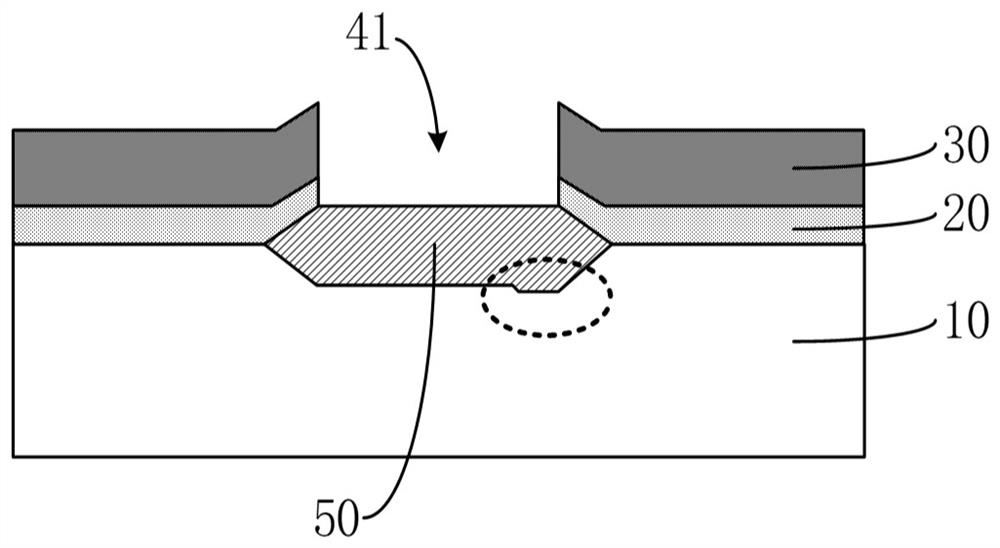

[0024] Figure 1A~1C It is a schematic cross-sectional view of the corresponding steps in the preparation method of a semiconductor device, which is combined below Figure 1A~1C The preparation method of the semiconductor device is described in detail, and the semiconductor device is an LDMOS device.

[0025] Please refer to Figure 1A , a substrate 10 is provided, a first dielectric layer 20, a second dielectric layer 30 and a patterned photoresist layer 40 are sequentially formed on the substrate 10, the patterned photoresist layer 40 has an opening 41, and the opening 41 exposes On the surface of the second dielectric layer 30 , the material of the first dielectric layer 20 may be oxide, and the material of the second dielectric layer 30 may be nitride.

[0026] Please refer to Figure 1B , using a dry etching process to etch the first dielectric layer 20 and the second dielectric layer 30 downward along the opening 41 to expose the surface of the substrate 10, and the ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com