Flame Retardant Yarns, Fabrics, Clothing Against Molten Metal Splash

A technology of molten metal and flame-retardant fabrics, which is applied in the fields of yarn, fabric, and clothing, and can solve the undisclosed problems of preventing molten metal from splashing and being expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

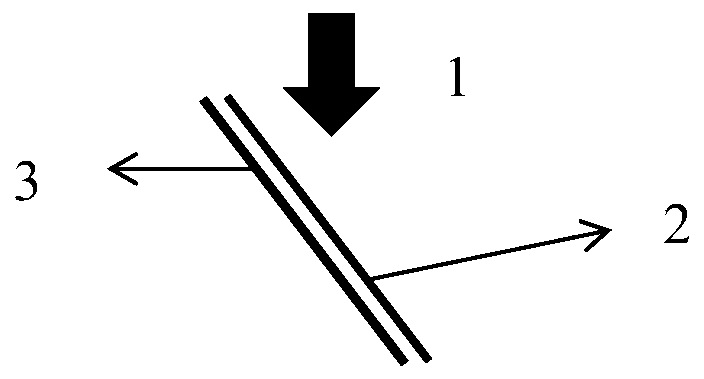

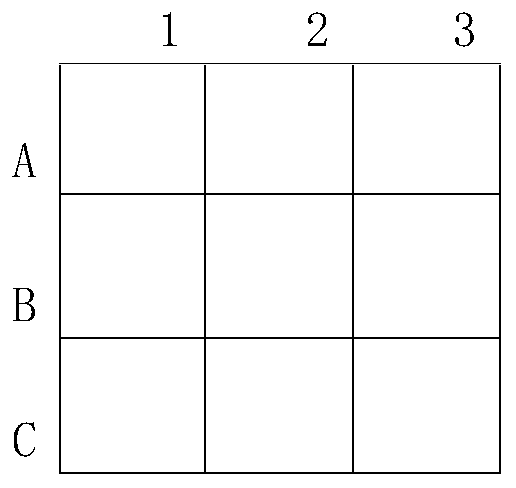

Image

Examples

Embodiment 1

[0057] A flame retardant yarn, fabric and garment that is resistant to molten metal spray. It is made of wool, silicon nitrogen flame retardant viscose and nylon mixed according to a certain proportion range, spun into fabrics, and then sewn into garments.

[0058] Among them, the mass ratio of wool, silicon nitrogen flame-retardant viscose and nylon fibers is as follows:

[0059] Wool: 20%;

[0060] Silicon nitrogen flame retardant viscose: 65%;

[0061] Nylon 6: 15%.

[0062] Among them, the percentage of the mass of wool to the mass of the silicon nitrogen flame retardant viscose is 30.769%.

Embodiment 2

[0064] A flame retardant yarn, fabric and garment that is resistant to molten metal spray. It is made of wool, silicon nitrogen flame retardant viscose and nylon mixed according to a certain proportion range, spun into fabrics, and then sewn into garments.

[0065] Among them, the mass ratio of wool, silicon nitrogen flame-retardant viscose and nylon fibers is as follows:

[0066] Wool: 20%;

[0067] Silicon nitrogen flame retardant viscose: 65%;

[0068] Nylon 66: 15%.

[0069] Among them, the percentage of the mass of wool to the mass of the silicon nitrogen flame retardant viscose is 30.769%.

Embodiment 3

[0071] A flame retardant yarn, fabric and garment that is resistant to molten metal spray. It is made of wool, silicon nitrogen flame retardant viscose and nylon mixed according to a certain proportion range, spun into fabrics, and then sewn into garments.

[0072] Among them, the mass ratio of wool, silicon nitrogen flame-retardant viscose and nylon fibers is as follows:

[0073] Wool: 30%;

[0074] Silicon nitrogen flame retardant viscose: 65%;

[0075] Nylon 66: 5%.

[0076] Among them, the percentage of the mass of wool to the mass of the silicon nitrogen flame retardant viscose is 46.154%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com