High-fluidity, high-flame-retardancy and high-toughness ABS (Acrylonitrile-Butadiene-Styrene) and preparation method thereof

A high-fluidity, high-flame-retardancy technology, applied in the field of high-fluidity, high-flame-retardancy, high-toughness ABS and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Corresponding to this formula, a method for preparing ABS with high fluidity, high flame retardancy and high toughness comprises the following steps:

[0031] 1) Pretreatment: Fully stir and mix AS powder, compound flame retardant composition, coupling agent, antioxidant, anti-dripping agent, and processing aid at 100-130°C;

[0032] 2) Put the pretreated mixture, ABS, and high-grade rubber powder in the mixer and mix them thoroughly;

[0033] 3) Put the fully mixed material in an extruder to melt, extrude and granulate.

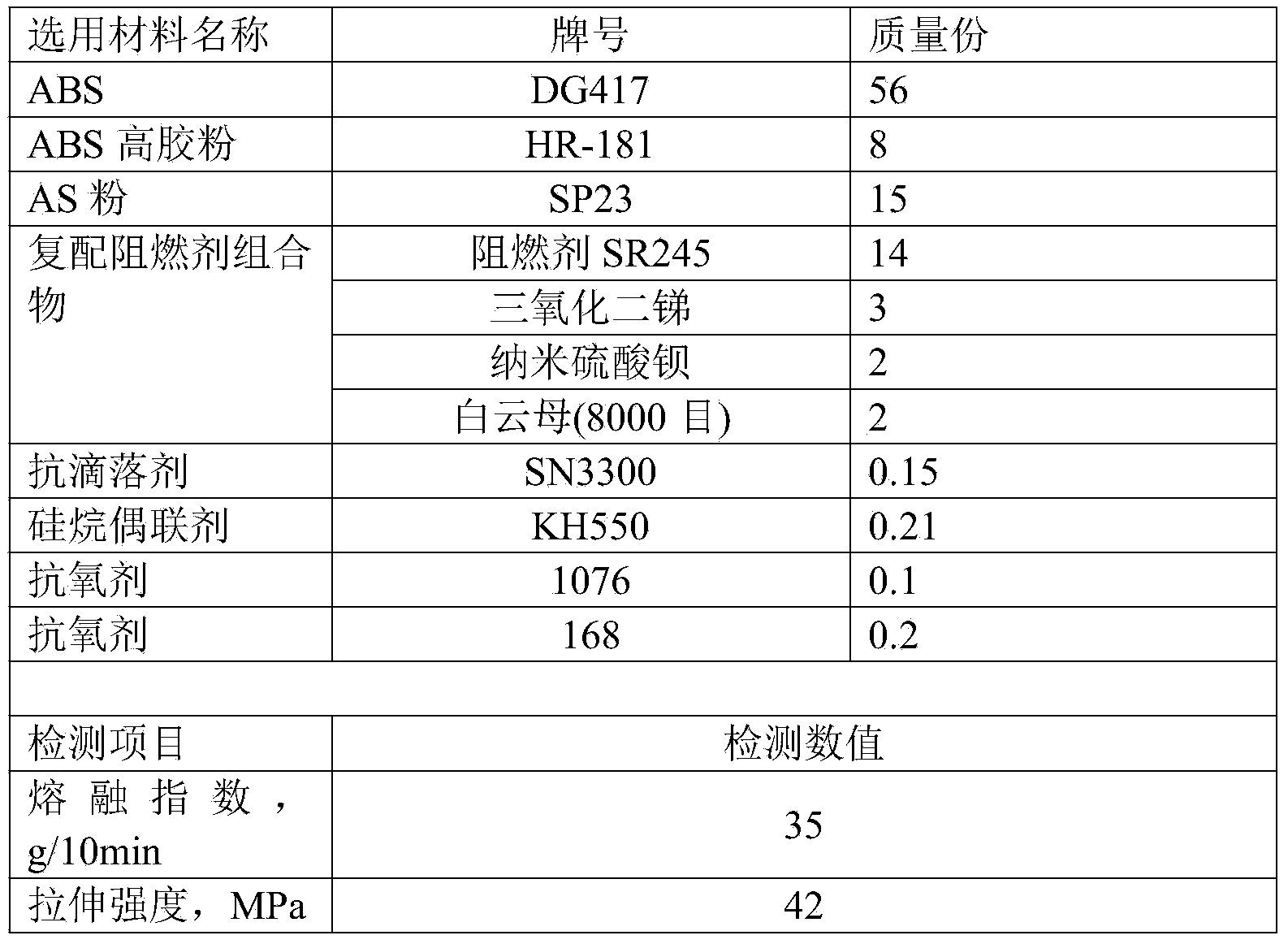

Embodiment 1

[0036] A high fluidity, high flame retardant and high toughness ABS, its formula composition is as follows:

[0037] Table 1:

[0038]

[0039]

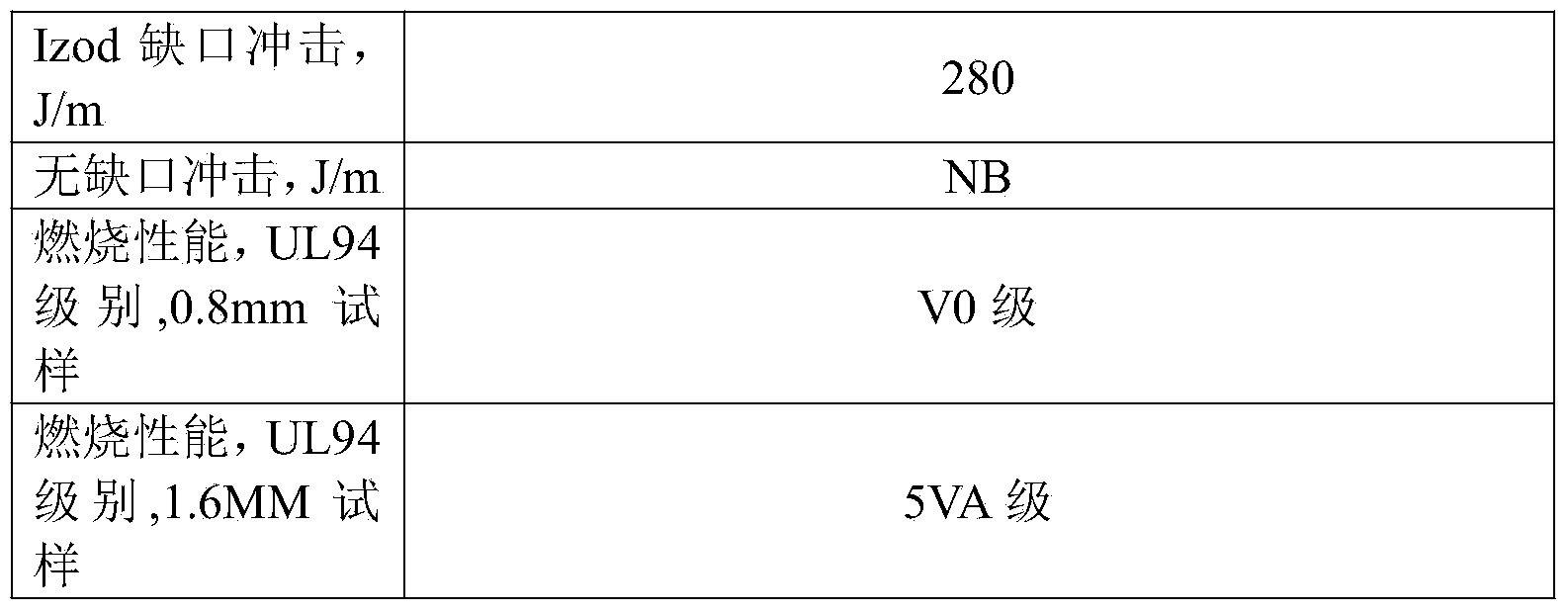

Embodiment 2

[0041] A high fluidity, high flame retardant and high toughness ABS, its formula composition is as follows:

[0042] Table 2:

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com