Air pressure type urea metering injection system with two urea pressure containers

A technology of pressure vessel and injection system, which is applied in the direction of exhaust treatment, exhaust device, machine/engine, etc., can solve the problem of high energy consumption of the battery, reduce the pressure wave in the pipe, improve the accuracy and stability of measurement, and eliminate adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

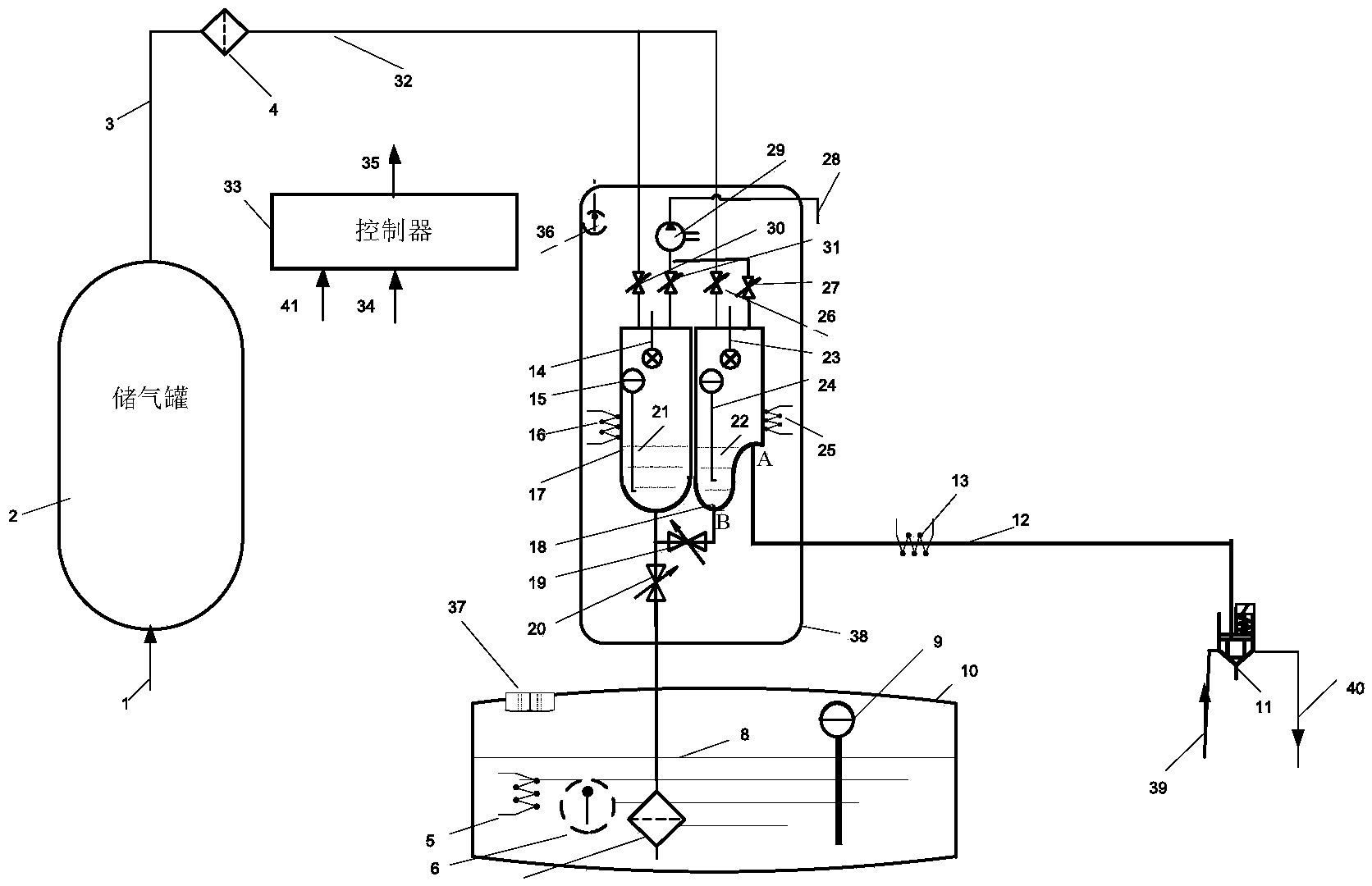

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

[0015] The invention is a urea injection system using a gas pressure source, wherein the gas pressure source can be a high-pressure gas storage bottle, or an air compressor and a gas storage tank, and the working principles of the two methods are similar. Now take the implementation of an air compressor and an air storage tank as an example.

[0016] The air storage tank 2 is inflated by a small air compressor through the compressed air inlet. As a gas pressure source for vehicles, the working pressure is generally 0.8-1.0MPa. 17 is urea pressure vessel 1, and the urea pressure vessel 1 volume that present embodiment selects is 1L, and gas pressure source and urea pressure vessel and relevant valve system constitute urea pump. The air intake solenoid valve 30 of the urea pressure vessel I is in the closed state, the connection switch solenoid valve 19 of the urea pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com