Object surface emissivity field calibration method

An on-site calibration, object surface technology, applied in radiation pyrometry, optical radiation measurement, measuring devices, etc., can solve the problems of inappropriate on-site temperature measurement, high accuracy, inconvenient to carry, etc., to achieve rapid temperature measurement and high accuracy , easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

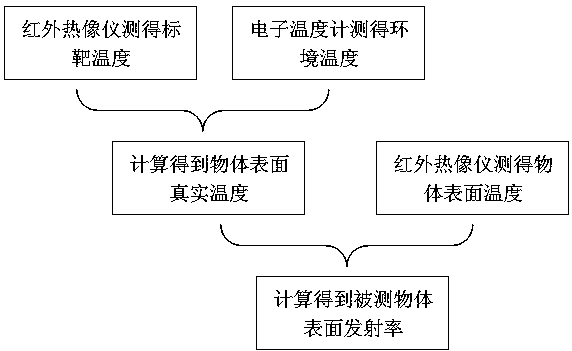

AI Technical Summary

Problems solved by technology

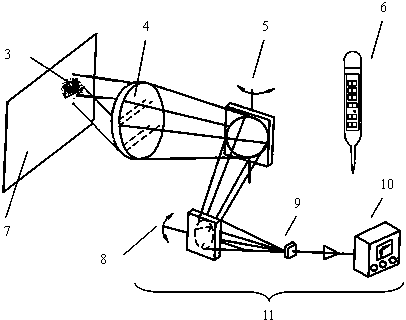

Method used

Image

Examples

Embodiment

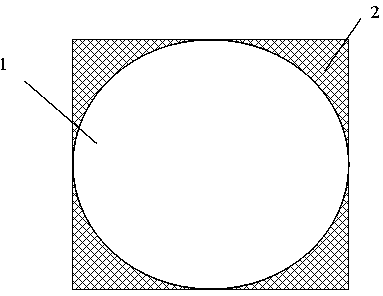

[0035] The present invention uses Japanese HRC paint to test, and the bottom surface is used as the on-site calibration object surface of the test.

[0036] The molecular structure of HRC coating is stable, and the heat radiation rate is high: it is close to 0.98 at 1030°C, above 0.95 in the range of 800°C-1200°C, and exceeds 0.9 in the range of 600°C-1300°C, and the coating thickness is 0.7mm.

[0037] The electric iron GC1420 can automatically adjust the temperature within the range of 60-250 ℃, weighs 1.06 kg, and has a power of 1200 watts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com