Doubly-fed wind generator high-voltage traversing rotor control method based on follow-up algorithm

A technology for wind turbines and doubly-fed generators, which is applied to the control field of high-voltage ride-through rotors of doubly-fed wind turbines, can solve the problems of inability to take into account equipment cost, prediction accuracy and computing efficiency, and short processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

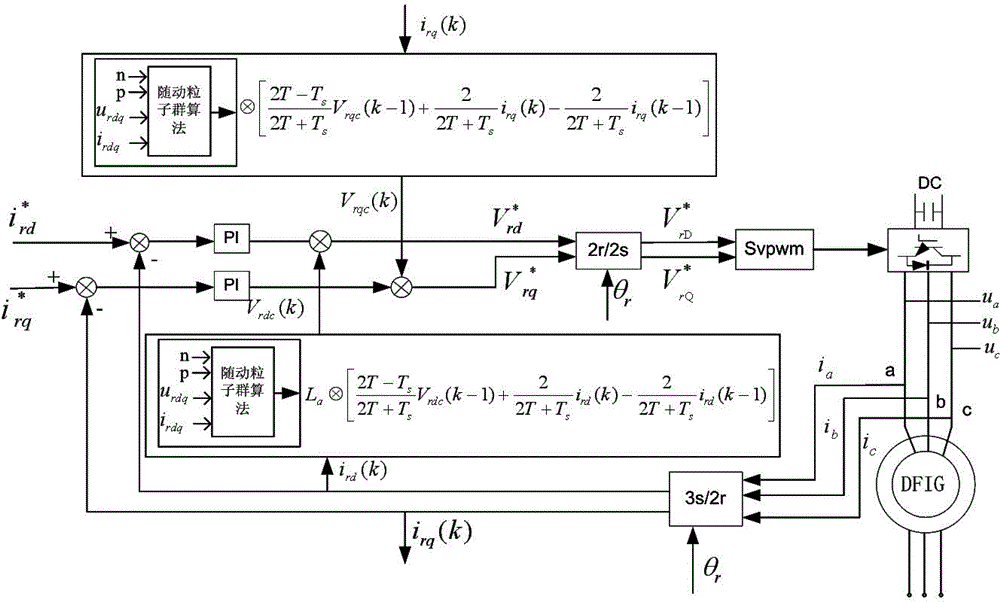

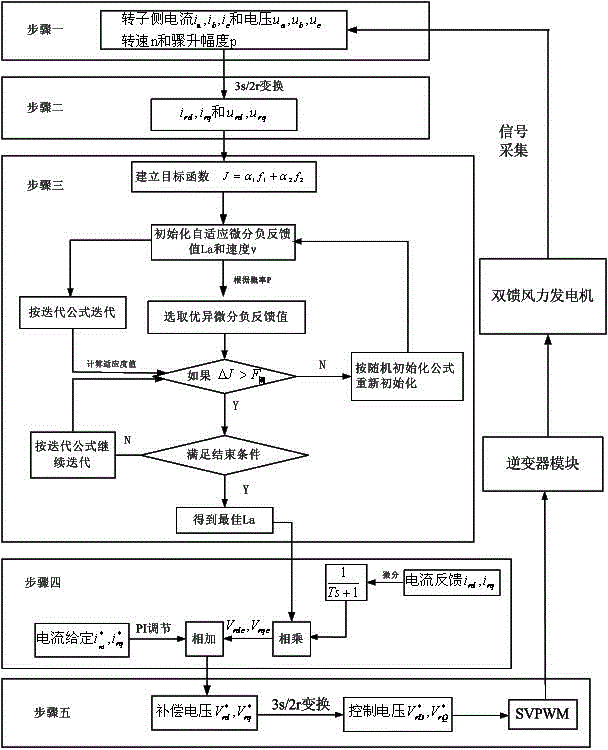

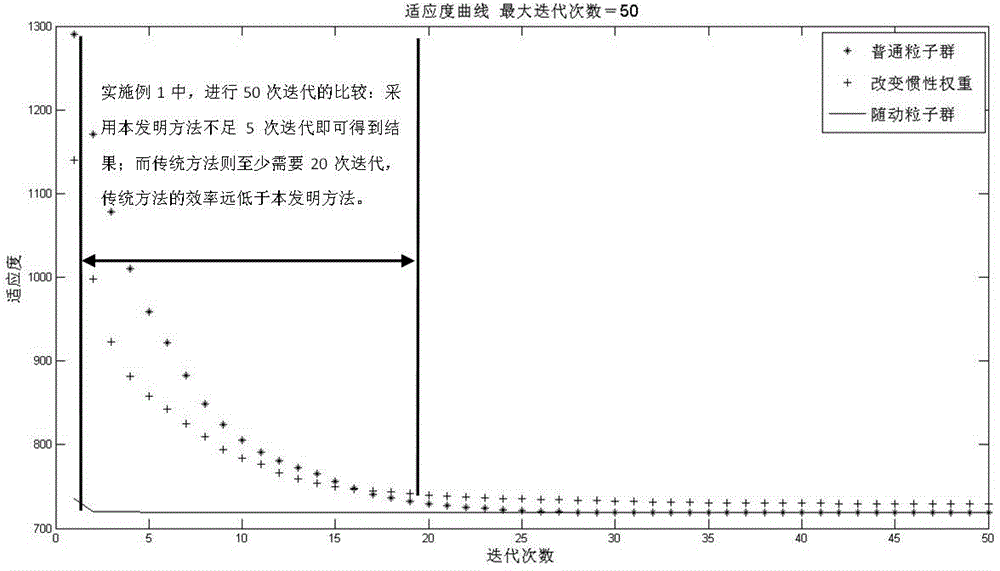

[0044] refer to figure 1 , in order to verify the feasibility and effectiveness of this method, the following experimental testing platform was built: a doubly-fed wind power generator, the initial voltage of the stator of the doubly-fed wind power generator is Us=690v, and the initial voltage of the rotor is Ur=220v , speed n=1800r / min. In Example 1, the sudden increase p=0.3, the comparison curves of the fitness of different algorithms are as follows figure 2 As shown, the example steps are as follows:

[0045] Step 1: Collect three-phase current, three-phase voltage, wind turbine speed n and grid voltage surge p from the rotor side of the double-fed wind turbine, where the three-phase current on the rotor side of the double-fed wind turbine is recorded as A phase current i a , B-phase current i b and C-phase current i c ; The three-phase voltage on the rotor side of the doubly-fed wind turbine is denoted as the A-phase voltage u a , B-phase voltage u b and C-phase v...

Embodiment 2

[0074]In Example 2, the maximum number of iterations M is set to 100, and the sudden increase is p=0.1. The comparison curve of the fitness of different algorithms is as follows: Figure 5 As shown, the example steps are as follows:

[0075] Step 1: Collect three-phase current, three-phase voltage, wind turbine speed n and grid voltage surge p from the rotor side of the double-fed wind turbine, where the three-phase current on the rotor side of the double-fed wind turbine is recorded as A phase current i a , B-phase current i b and C-phase current i c ; The three-phase voltage on the rotor side of the doubly-fed wind turbine is denoted as the A-phase voltage u a , B-phase voltage u b and C-phase voltage u c ;

[0076] Step 2: Collect the collected three-phase current A-phase current i on the rotor side of the doubly-fed wind turbine a , B-phase current i b and C-phase current i c Transform from the three-phase stationary coordinate system to the two-phase synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com