Interactive model reference adaptive speed and stator resistance identification method based on sliding-mode control

A technology of stator resistance and model reference, used in the control of generators, control of electromechanical brakes, control of electromechanical transmissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

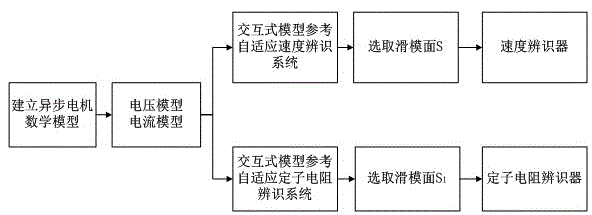

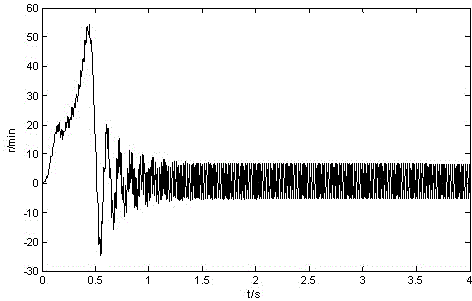

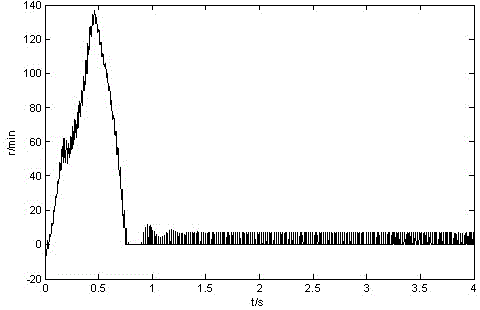

[0068] Embodiment 1: as Figure 1-4 As shown, an interactive model reference adaptive speed and stator resistance identification method based on sliding mode control, first in the two-phase static Under the coordinate system, establish the mathematical model of the asynchronous motor; calculate the voltage model and current model according to the mathematical model of the asynchronous motor, observe the rotor flux linkage through the voltage model and current model, and then construct an interactive model to refer to the adaptive speed identification system and interactive Model reference adaptive stator resistance identification system; according to the constructed interactive model reference adaptive speed identification system and interactive model reference adaptive stator resistance identification system, the sliding mode control method is used to design the speed identifier and stator resistance identifier To identify the speed and stator resistance of the asynchronous...

Embodiment 2

[0094] Embodiment 2: as Figure 1-4 As shown, an interactive model reference adaptive speed and stator resistance identification method based on sliding mode control, the steps of the method are as follows: first, in the two-phase static Under the coordinate system, establish the mathematical model of the asynchronous motor; calculate the voltage model and current model according to the mathematical model of the asynchronous motor, observe the rotor flux linkage through the voltage model and current model, and then construct an interactive model to refer to the adaptive speed identification system and interactive Model reference adaptive stator resistance identification system; according to the constructed interactive model reference adaptive speed identification system and interactive model reference adaptive stator resistance identification system, the sliding mode control method is used to design the speed identifier and stator resistance identifier To identify the speed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com