Variable frequency controller for alternating current motor

A frequency conversion controller and AC motor technology, applied in the field of frequency conversion control, can solve problems such as frequency conversion and speed regulation of AC motors, achieve smooth current without impact, prolong service life, and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

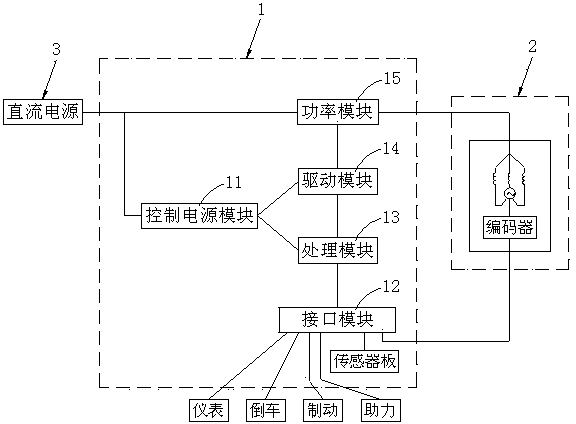

[0019] Please refer to figure 1 As shown, an AC motor frequency conversion controller 1 includes a control power supply module 11, an interface module 12, a processing module 13, a drive module 14 and a power module 15; wherein,

[0020] The control power supply module 11 is configured to provide control power supply for the processing module 13 and the drive module 14;

[0021] The interface module 12 is configured to receive control signals input from the outside;

[0022] The processing module 13 is configured to perform arithmetic processing on the control signal received by the interface module 12 from the outside, and output a three-phase voltage control signal;

[0023] The drive module 14 is configured to convert the three-phase voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com