Three-phase four-switch direct current brushless motor space voltage vector control circuit and method

A brushless DC motor and space voltage vector technology, which is applied in the direction of DC motor speed/torque control, vector control system, motor generator control, etc., can solve the problem of large torque ripple and achieve voltage regulation and frequency conversion Speed, good torque ripple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings,

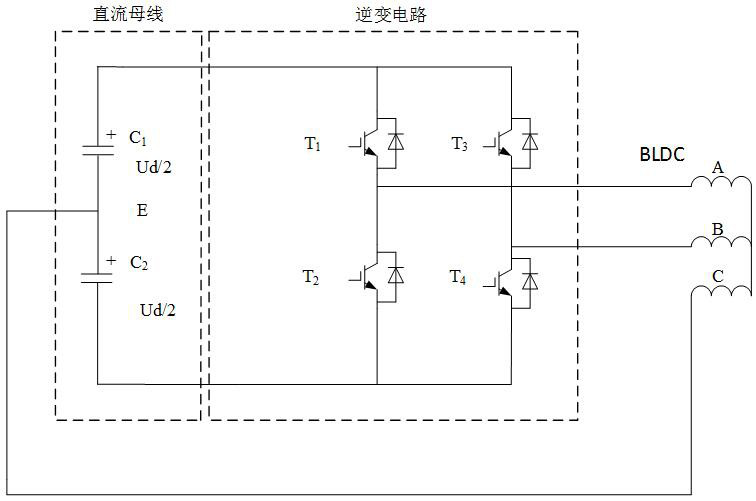

[0016] figure 1 As shown, the control circuit of the three-phase four-switch DC brushless motor space voltage vector of the present invention specifically includes a DC bus part and an inverter part, wherein the inverter circuit of the inverter part is connected with the power supply and the A-phase, B-phase of the motor. The phase load is connected, and the C phase of the motor is connected to the capacitor C 1 , C 2 The neutral point E is connected.

[0017] First, before the starting process, it is stipulated that the counterclockwise rotation is forward rotation, and the motor runs in the forward rotation state.

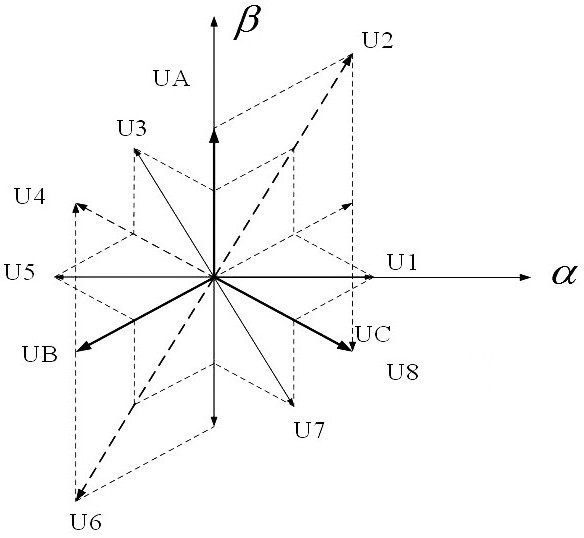

[0018] like figure 2 As shown, an α-β coordinate system is established.

[0019] Assume that the A-phase voltage vector is in the 90° direction of the α-β coordinate system, the B-phase voltage vector is in the -150° direction, and the C-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com