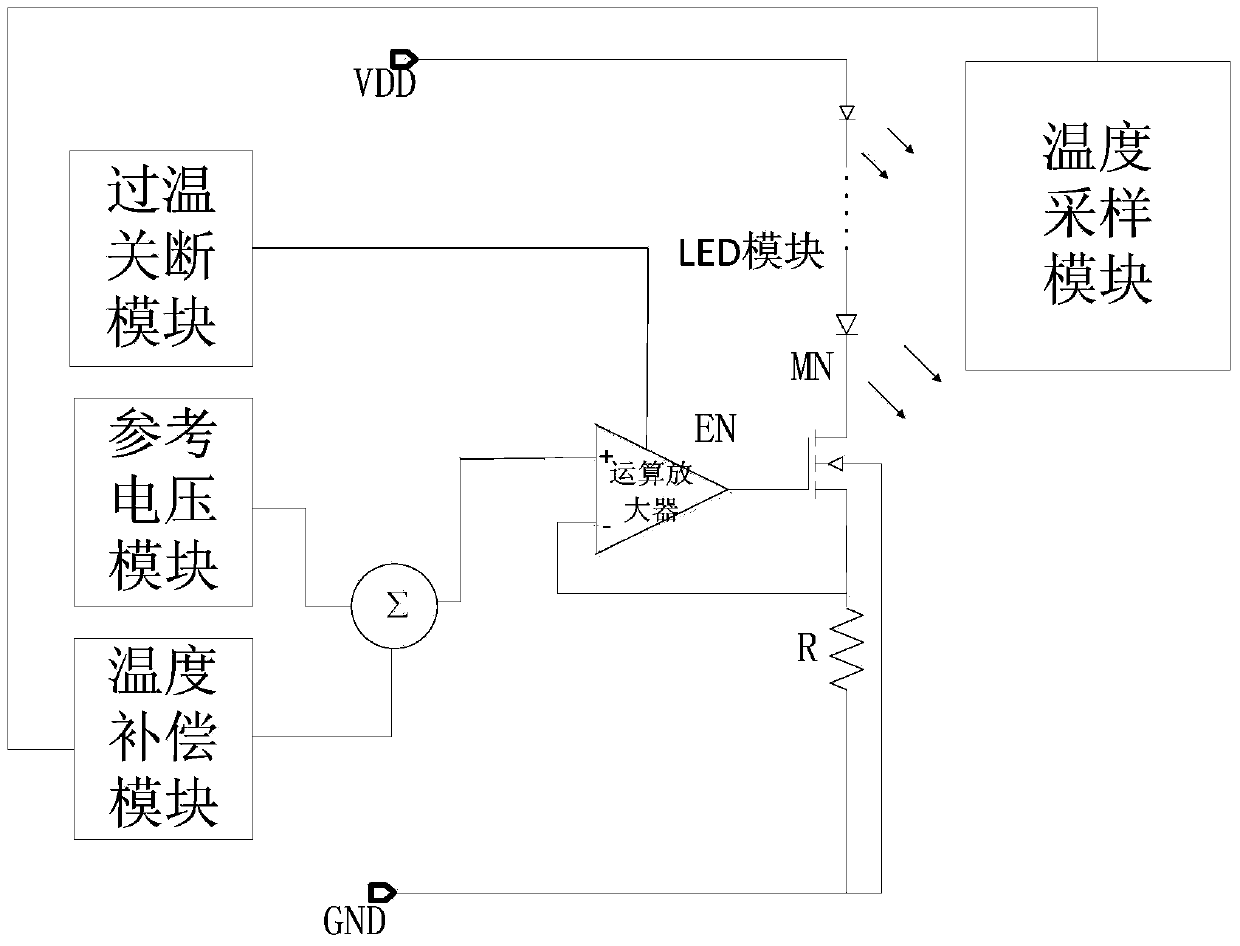

Temperature compensating circuit for linearly driving LED

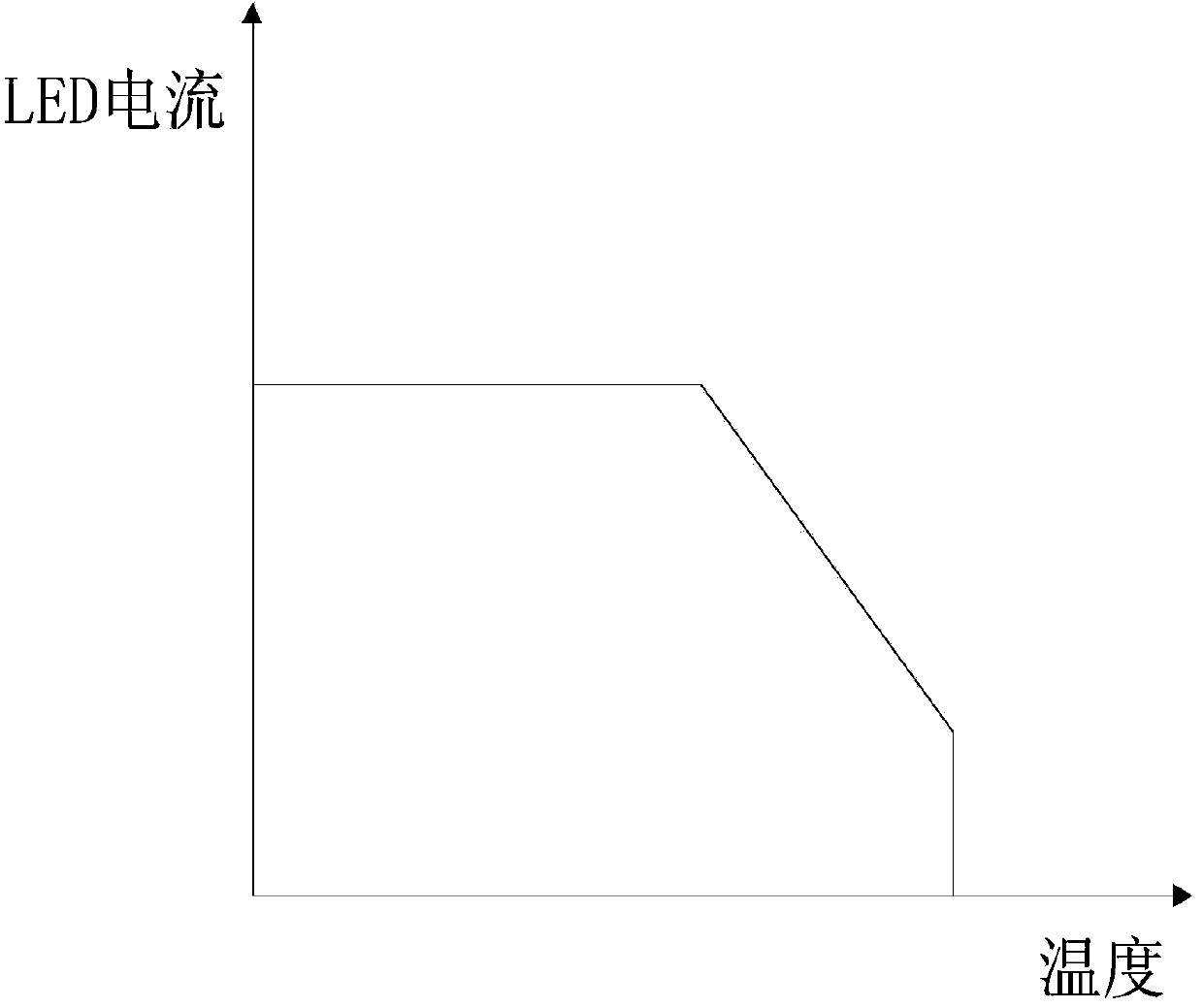

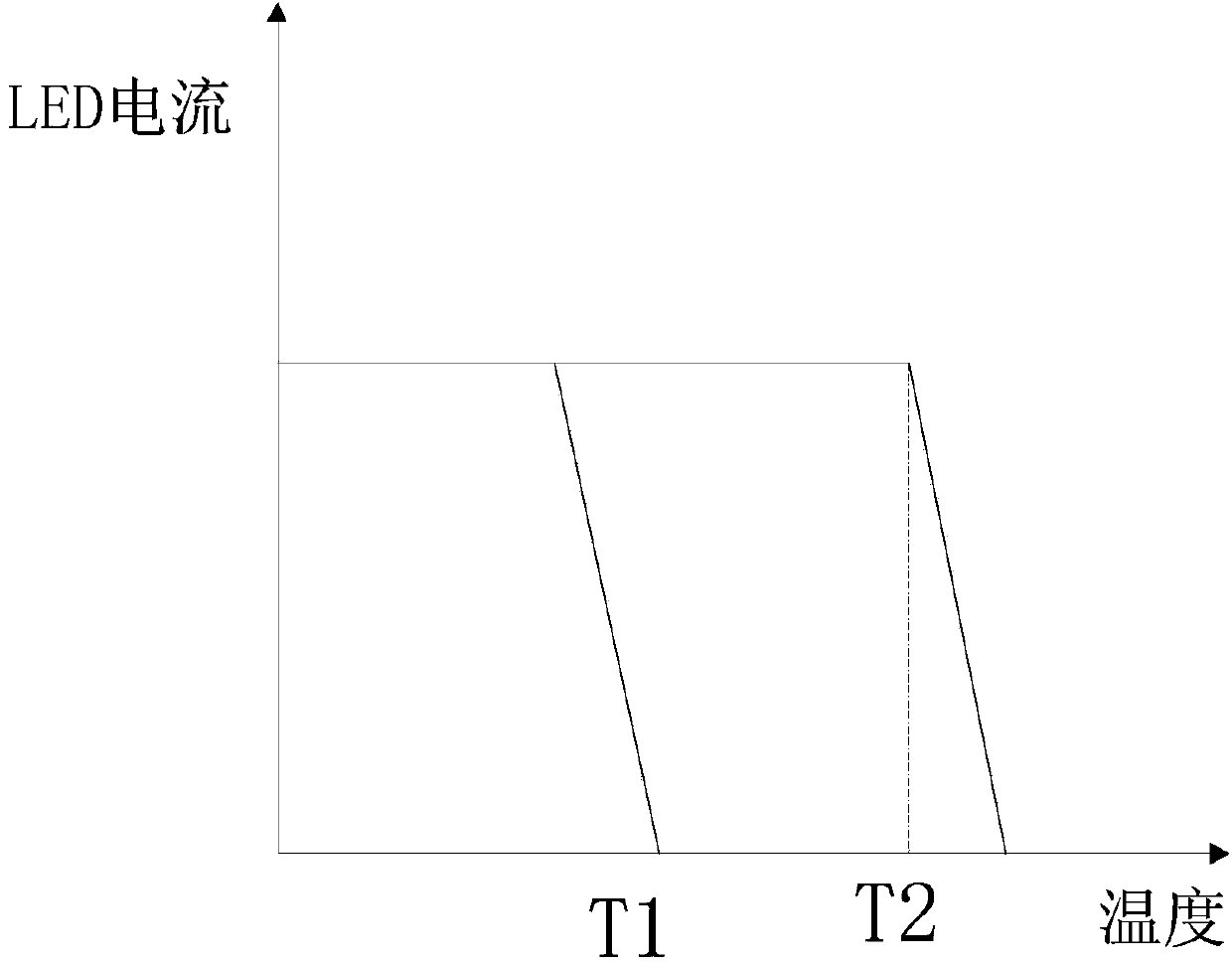

A temperature compensation circuit and linear drive technology, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems of performance damage such as LED life, continuous thermal opening, inability to timely and accurate shutdown, etc., to achieve The effect of temperature double protection and current adaptive reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Such as Figure 4 As shown, the over-temperature shutdown module in this example is composed of PMOS transistors PM1, PM2, PM3, PM4, NMOS transistors NM1, NM2, NM3, NM4, NM5, triode NPN1, resistor R1, and inverter INV; among them, PM1, The source of PM2, PM3, PM4 is connected to the power supply VDD; the gate and drain of PM1 are interconnected, the gate is connected to the gate of PM2, and the drain is connected to the drain of NM; the source of NM2 is grounded to GND; NM2, NM1 The gates of NM3, NM5 are interconnected; the source of NM1 is grounded to GND, and the drain and gate are connected to the external current source I_BIAS; the source of PM2 is connected to the power supply VDD, and the drain is connected to the input terminal of the inverter INV and the transistor The collector of NPN1; the emitter of transistor NPN1 is grounded to GND, and its base is connected to the drain of PM4, and its base is also grounded to GND after passing through R1; the source of PM3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com