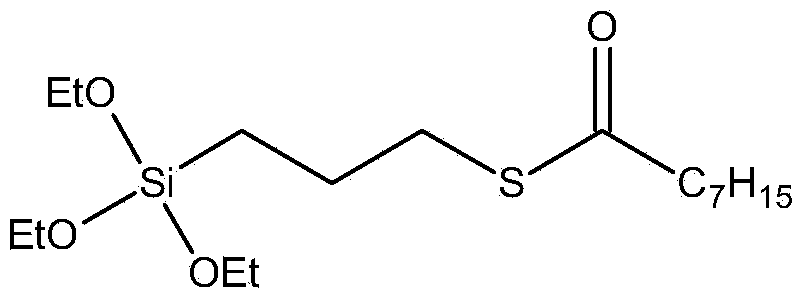

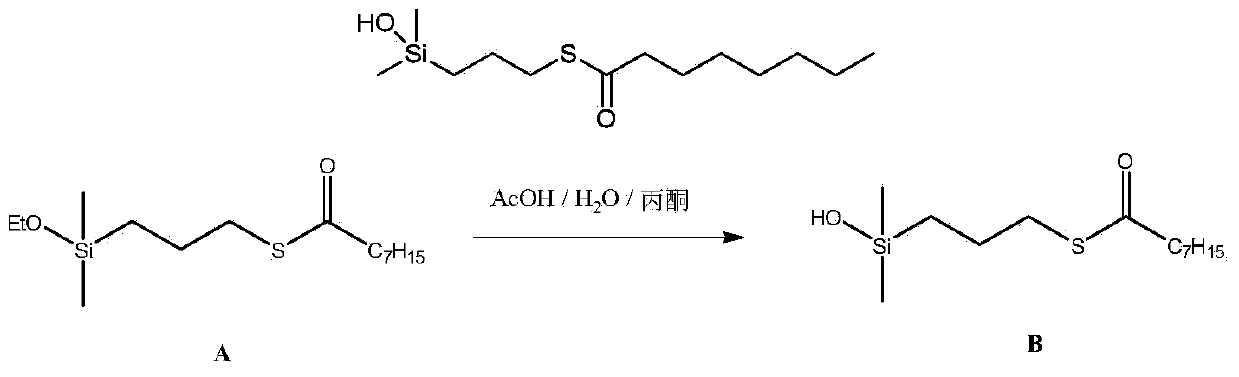

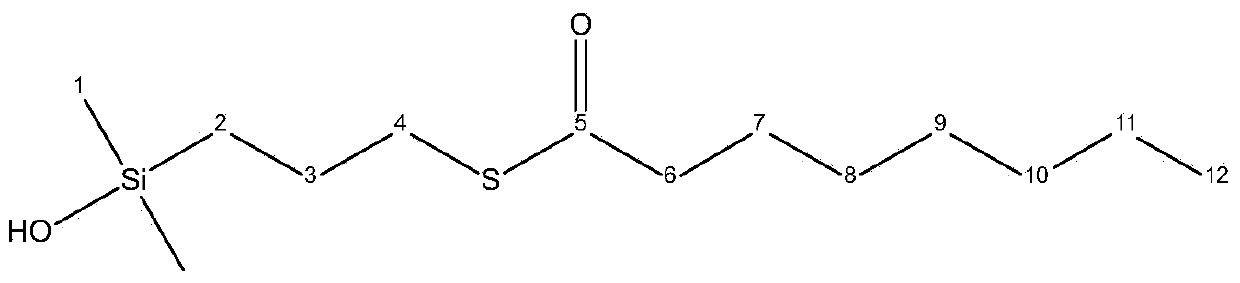

Blocked mercaptosilane coupling agent

A technology of mercaptosilane, methyl, applied in the field of reinforcing inorganic fillers and diene elastomers, which can solve the problems of premature vulcanization, impossible operation and industrial processing of rubber compositions, high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] I. Measurements and Tests Used

[0036] The rubber compositions in which the coupling agents were tested were characterized before and after curing as described below.

[0037] I-1. Tensile test

[0038] These tensile tests make it possible to determine elastic stress and fracture properties. These tests were performed according to the French standard NF T46-002, September 1988, unless otherwise indicated. Nominal secant modulus (or apparent stress in MPa) at 100% elongation (denoted as M100) and at 300% elongation (M300) in the second elongation (i.e. at the measured after an adaptation cycle at the elongation rate).

[0039] I-2. Kinetic properties

[0040] The kinetic properties ΔG* and tan(δ) were measured on a viscosity analyzer (Metravib VA4000) according to standard ASTM D5992-96 max. Samples of vulcanized compositions (thickness 4mm, cross-section 400mm 2 The response of the cylindrical sample). A strain amplitude sweep was performed from 0.1% to 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com