Mainframe-control-based dedusting system for multiple cascaded solar panels

A solar panel and host technology, applied in photovoltaic power generation, electrical components, cleaning by electrostatic method, etc., can solve the problems of complex structure, unusable, short service life, etc., to simplify dust removal operation, avoid distance limitation, controllable good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

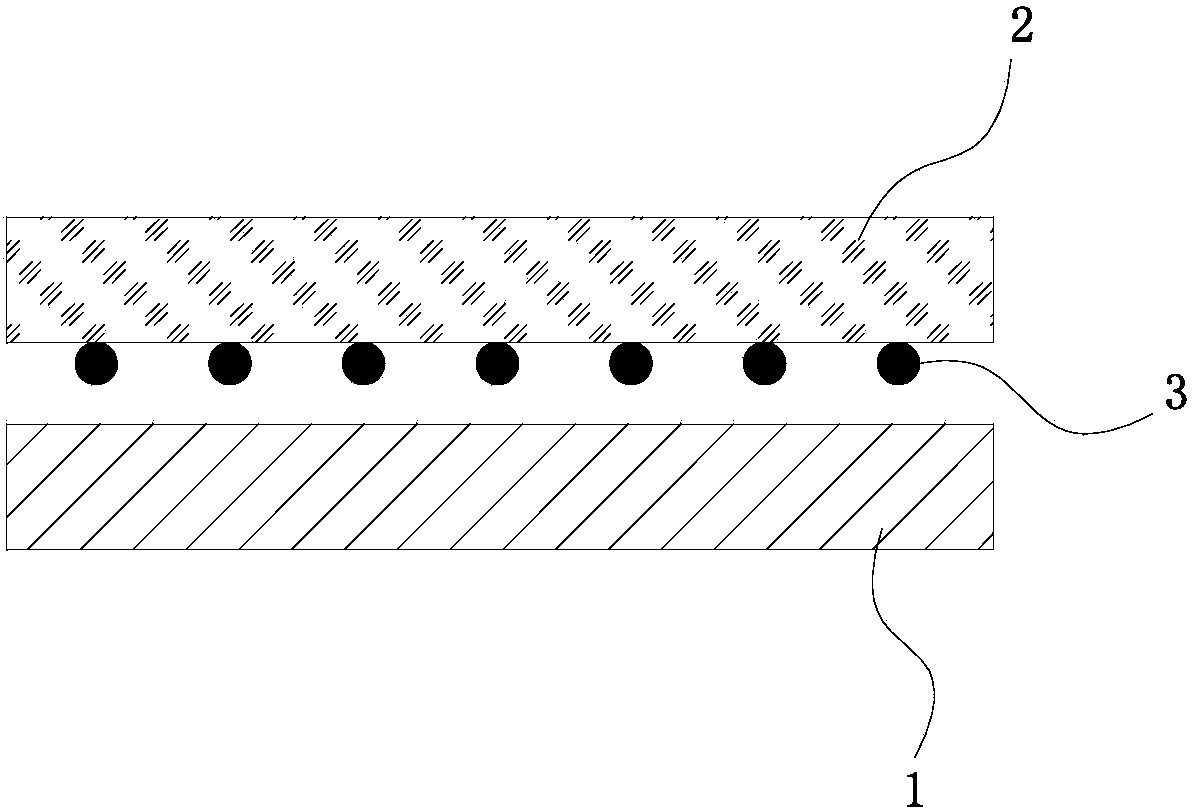

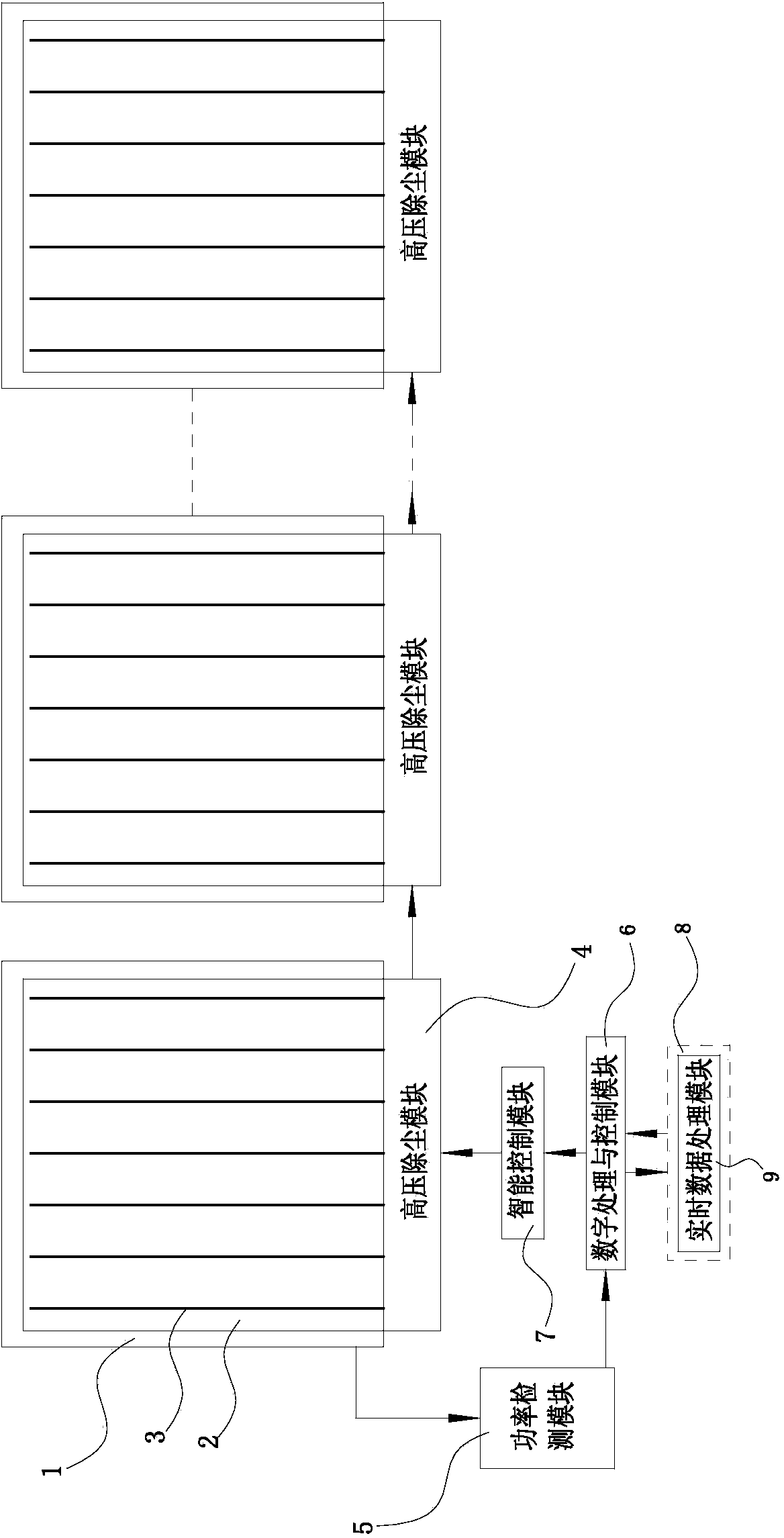

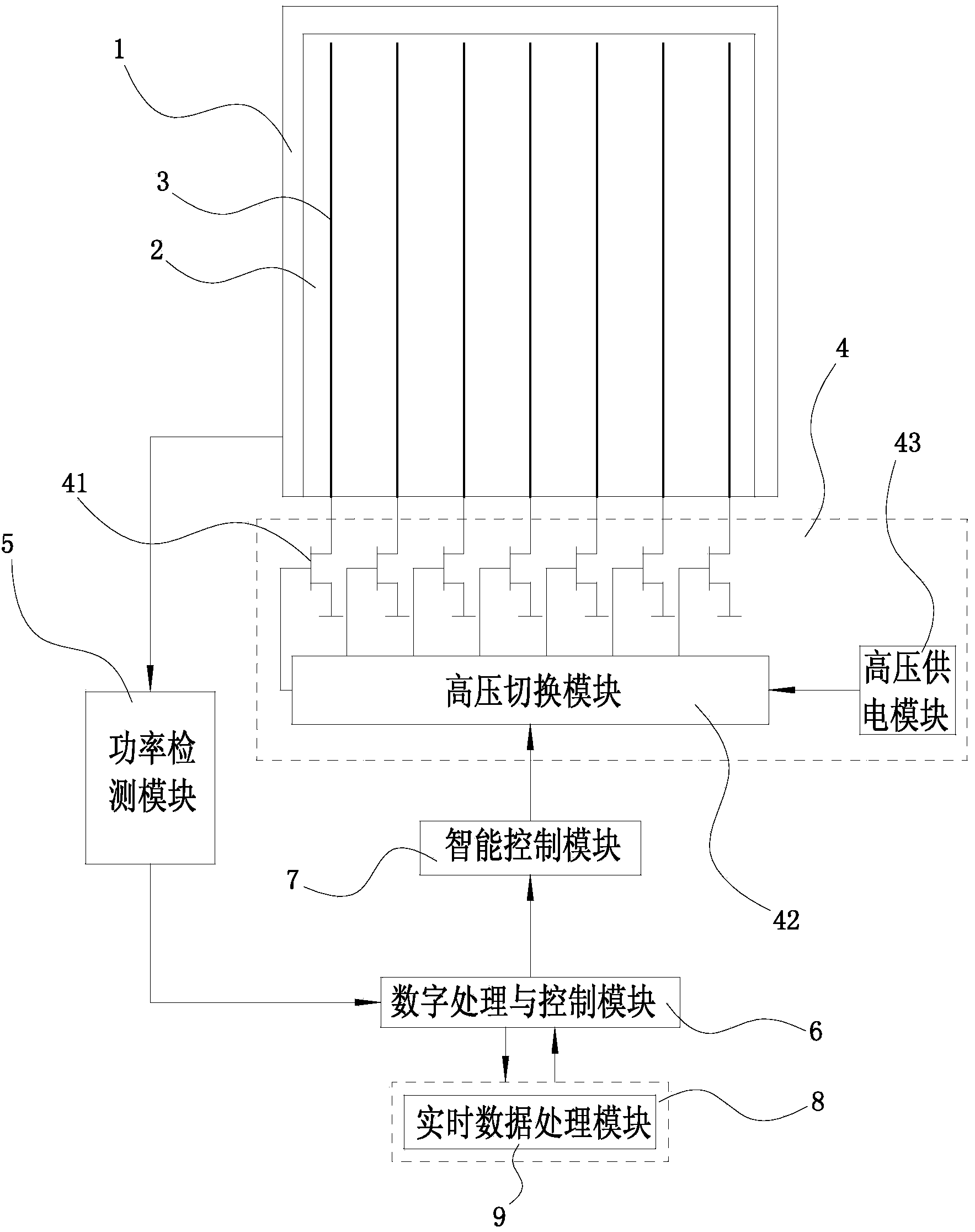

[0015] See Figure 1 to Figure 3 , the present invention includes a plurality of solar cell panels 1, and the solar cell panels 1 are respectively equipped with a glass protective layer 2;

[0016] The lower surface of the glass protective layer 2 is respectively equipped with a plurality of parallel electrodes 3, the ends of the electrodes 3 are connected to the high-voltage dust removal module 4, and the adjacent high-voltage dust removal modules 4 are cascaded with each other; High-voltage switch 41, high-voltage switch 41 is electrically connected to high-voltage switching module 42, high-voltage switching module 42 is powered by high-voltage power supply module 43, high-voltage switching module 42 alternately applies high voltage to electrodes 3, a fluctuating electrostatic field is generated between electrodes 3, and the glass protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com