A non-contact laser on-line detection bar straightness mechanism and detection method

A non-contact, straightness technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of lack of basis for straightening bars, low detection efficiency, and inability to guarantee the straightness of bars. Low operating efficiency, improved straightening efficiency, and the effect of improving straightening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

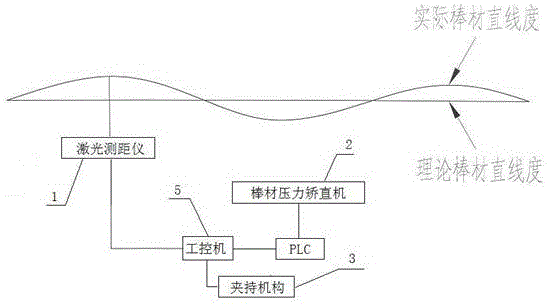

[0022] The pressure straightening machine is to support the workpiece with the original bending between the two movable fulcrums of the workbench, and use the pressure head to align the most curved place for reverse bending. When the bending amount is equal to the springback amount , After the indenter is withdrawn, the curved parts of the workpiece become straight, so that each curved part of the workpiece can be straightened. Since the bending amount set by experience is difficult to be exactly equal to the springback amount of the workpiece, it is necessary to straighten through repeated bending, which determines that the straightening efficiency of the pressure straightening machine is relatively low. At present, in China, most of the straightening is performed by manual experience. There is no basis for whether the bar is qualified or not after straightening. Bars need to be re-lined and straightened, which seriously affects the production efficiency of the bar pressure l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com