Method for preparing elastic ground mat by using waste rubber and waste plastic

A technology of waste plastics and elastic floor, which is applied in the direction of rubber layered products, chemical instruments and methods, layered products, etc., and can solve the problems of increasing the strength of floor mats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

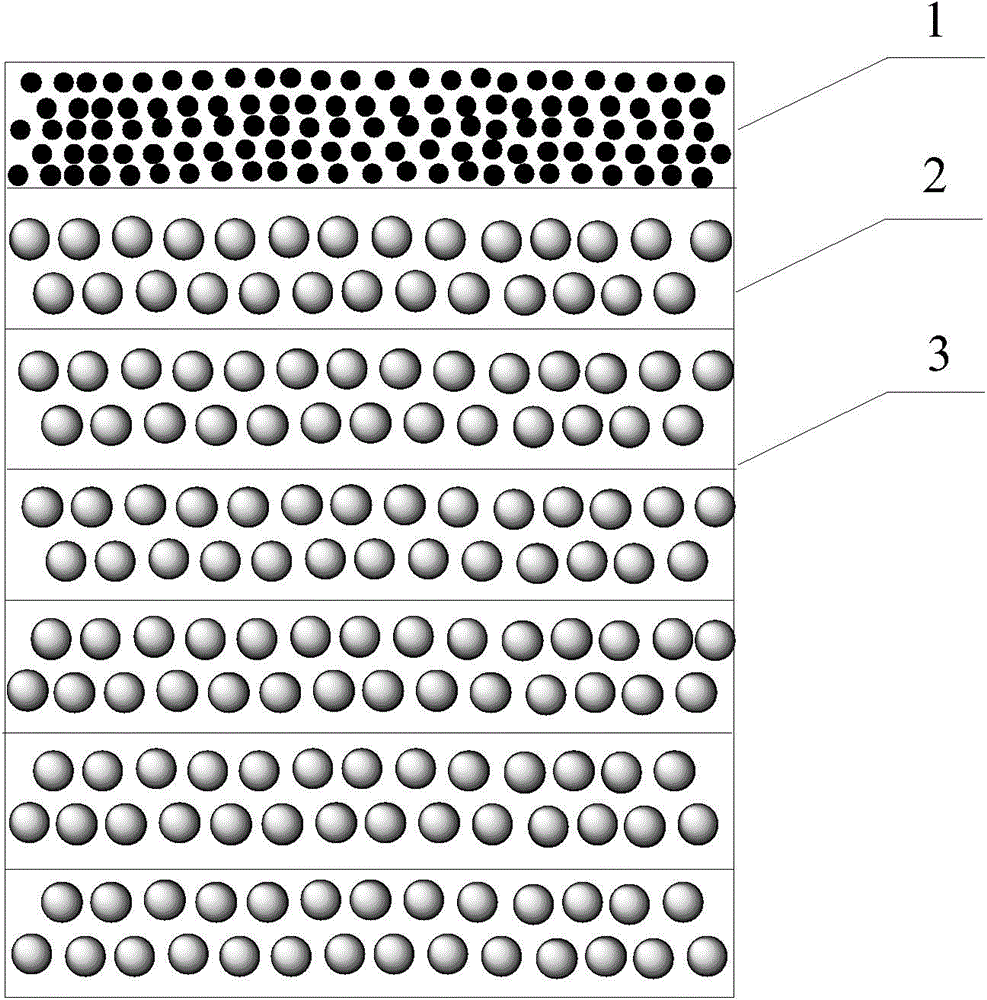

[0025] A method for preparing elastic floor mats from waste rubber and waste plastics, comprising the steps of:

[0026] A. Remove the steel wire from the waste rubber tires and use a pulverizer to crush them into waste rubber particles with a particle size of 20-30 mesh;

[0027] B. Remove the sand from the packaging plastic film and cut it into a suitable mold size;

[0028] C. Add a layer of waste rubber particles in the mold, cover with a layer of plastic film, add a layer of rubber powder after alternating 6 layers, 150 o Under the condition of C temperature and 2Mpa pressure, it can be pressed into an elastic floor mat at one time.

[0029] Technical performance requirements Elongation at break % ≥45 Compression deformation % ≤10 Resilience % ≥40

Embodiment 2

[0030] Embodiment 2, a kind of method that waste rubber and waste plastics prepare elastic floor mat, comprises the steps:

[0031] A. Remove the steel wire from the waste rubber tires and use a pulverizer to break them into waste rubber particles;

[0032] B. Remove the sand from the waste plastic film and cut it into a suitable mold size;

[0033] C. Add a layer of waste rubber particles in the mold, cover with a layer of plastic film, add a layer of rubber powder after alternating 6 layers, 120 o C. Under the pressure of 2Mpa, it can be pressed into an elastic floor mat at one time.

[0034] The particle size of the waste rubber waste rubber particles is 20-30 mesh.

[0035] The waste plastic film is an agricultural plastic film.

[0036] The waste rubber particles have been modified, and the modification method is as follows:

[0037] (1) Weigh the following raw materials by weight kg:

[0038] Waste rubber particles 60, dicyclohexyl phthalate 2, tripolyglycerol di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com