A special driving positioning detection device for aluminum profile oxidation and a special driving

A positioning detection device, aluminum profile oxidation technology, applied in the direction of anodic oxidation, cell, electrolysis process, etc., can solve the problems of driving positioning deviation, complexity, displacement accumulation error, etc., to achieve error compensation or elimination of displacement accumulation error, The effect of overcoming inconsistency of movement, simple and feasible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those of ordinary skill in the art to better understand the essence of the present invention, specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

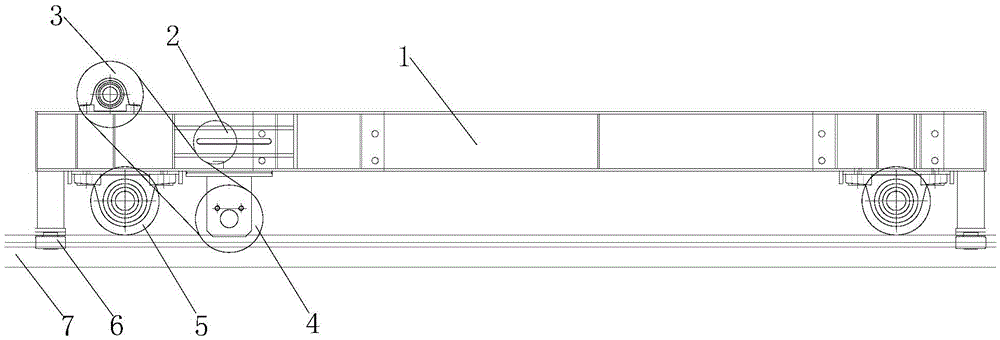

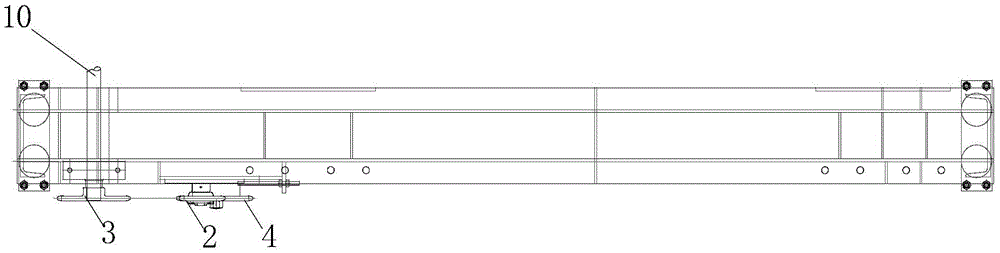

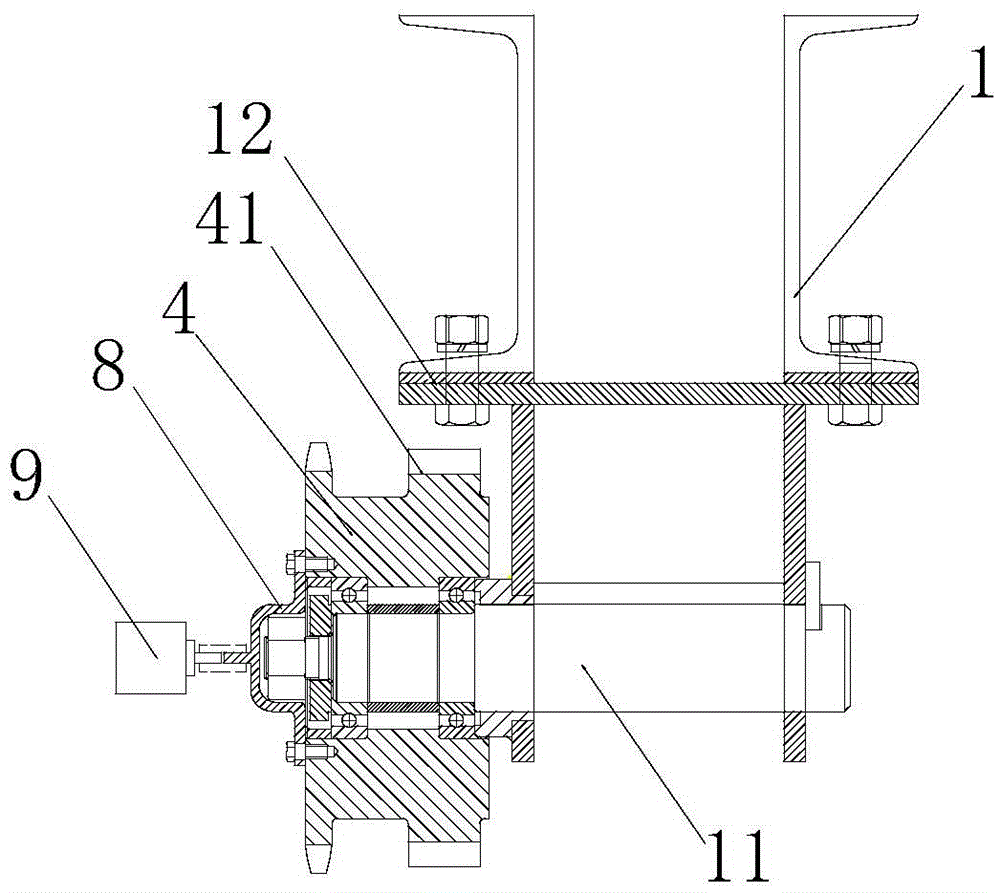

[0029] Such as Figure 1-Figure 6 As shown, an aluminum profile oxidation driving positioning detection device includes: end beam 1, tension wheel 2, driving sprocket 3, driven sprocket 4, wheel 5, guide wheel 6, rack 7, and encoder seat 8. And encoder 9.

[0030] Among them, the end beam 1 is supported by two wheels 5, and the end beam 1 has a guiding device composed of guide wheels 6 at both ends of the end beam 1 to guide the end beam during movement. The driving sprocket 3 is fixedly connected with the transmission shaft 10, and the transmission shaft 10 is rotatably connected with the transmission shaft seat fixed on the end beam 1. The driving sprocket 3 drives the driven sprocket 4 through the chain to move, in order to ensure that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com