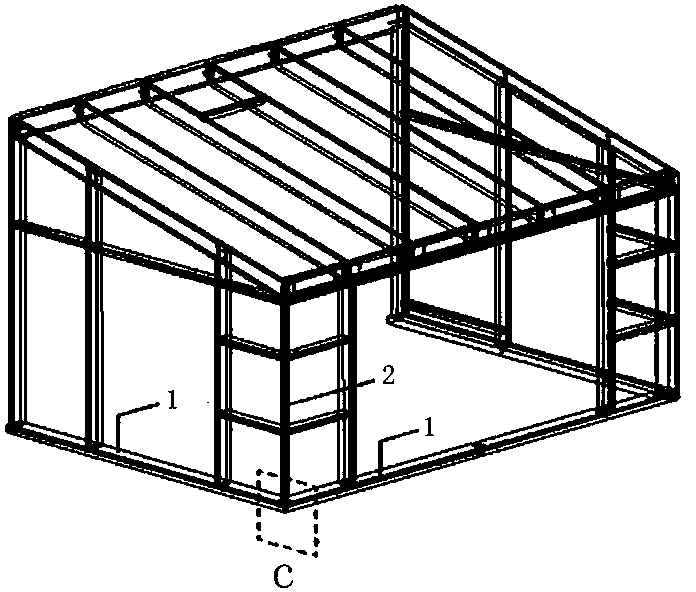

Framework connecting structure for sunlight room

A technology of connecting structure and sunshine room, which is applied in the field of frame connecting structure of sunshine room, can solve the problems of poor overall strength, stability and integrity of easily damaged timber components, affecting the quality of installation and construction, etc., so as to improve processing accuracy and production efficiency. The effect of improving the stability and integrity, and improving the accuracy and strength of the corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

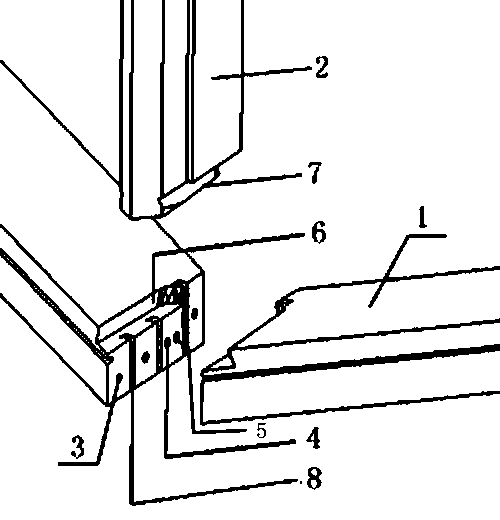

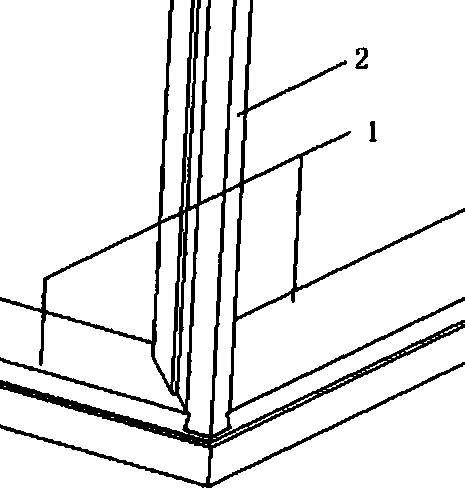

[0015] Embodiment: The frame connection of the aluminum-clad wood sun room according to the present invention, that is, the connection between the bottom frame and the bottom frame is connected by a round tenon rod and a dovetail connector. After the connection end of the bottom frame 1 is cut at 45 degrees, the Make a round hole on the side of the end, and make the positions of the round holes on the side of the end of the two bottom frames 1 correspond to each other. Open the hole for the dovetail connector on the 145-degree angle surface of the bottom frame. See figure 2 , 3 As shown; at the same time, a half dovetail groove is opened on the 45-degree angle surface 3 of the bottom frame 1, and after the two bottom frames 1 are connected at 90 degrees, a complete dovetail groove is formed. The end of the corner column 2 connected with the bottom frame 1 is provided with a dovetail male head. The connection tolerance of the dovetail female groove formed by the two bottom fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com