Combined type wind wheel blade and wind generating set comprising same

A combined technology of wind rotor blades, which is applied in the field of wind turbine components and wind rotor blades, can solve the problems of reducing the wind energy efficiency of blades, cumbersome assembly work, and uneven blade surfaces, so as to promote development and popularization, and the combination method is simple Fast, good aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be described in detail in combination with specific examples and accompanying drawings.

[0042] In order to overcome the problems existing in the existing combined wind rotor blade connection method, the present invention provides a combined wind rotor blade, and the combined segments are connected by a flange connection structure of a wedge strip connection type.

[0043] The following only takes the two-stage combined wind rotor blade as an example to describe in detail, and other multi-stage combinations refer to the two-stage combination.

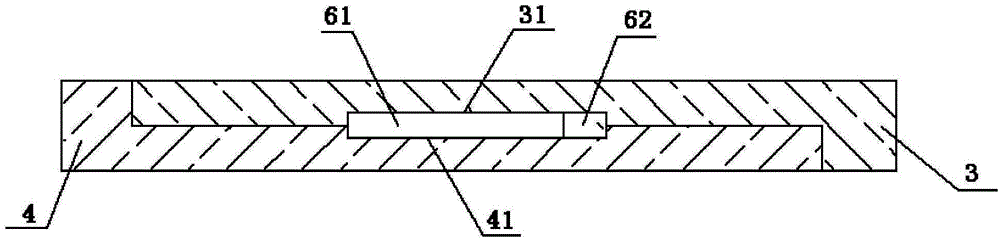

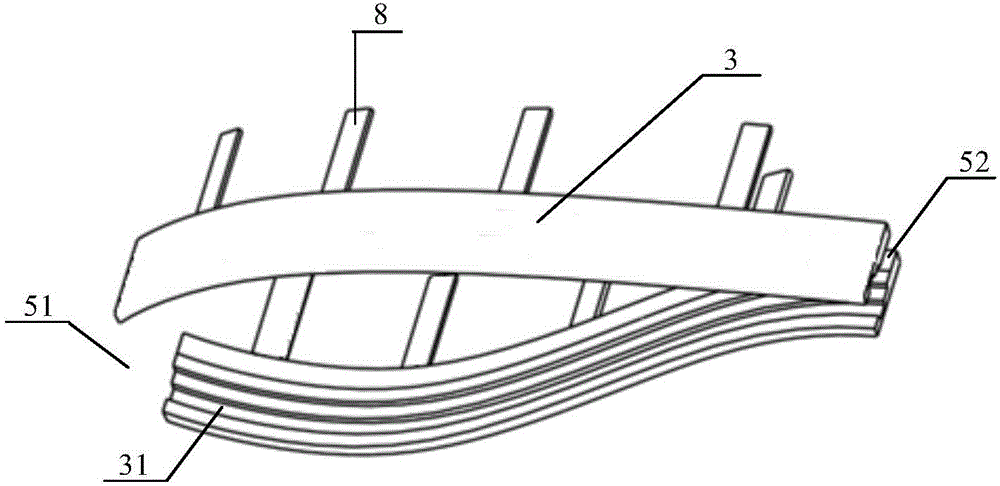

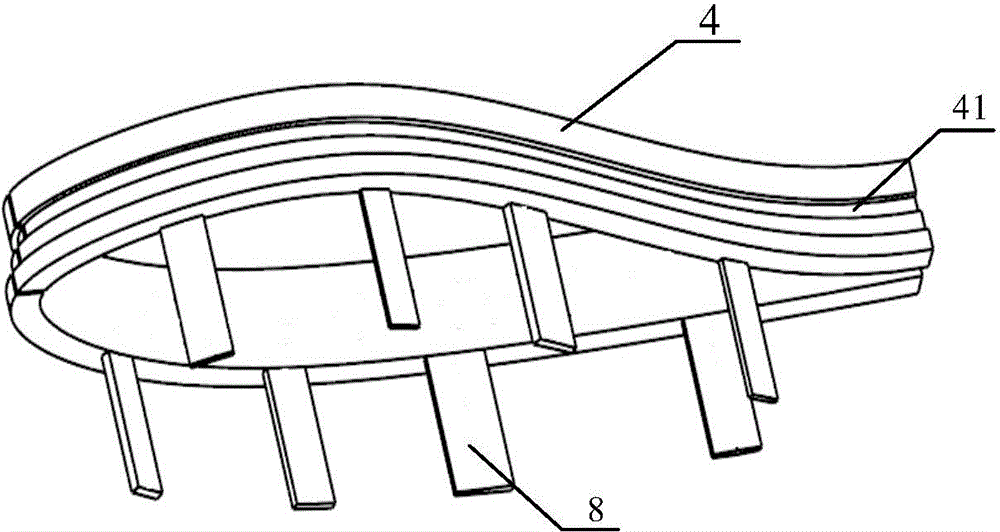

[0044] Such as Figure 7 As shown, the wind rotor blade includes a first composite section 1 and a second composite section 2, and among the butt end faces of the two, the end face near the blade root is connected to the outer flange 3, and the end face far away from the blade root is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com