Centrifugal Compressor Case Bleed Air Recirculation Structure with Variable Geometry

A technology of geometric size and gas recirculation, applied in the field of compressors, can solve the problem of not being able to optimize the working range of centrifugal compressors, and achieve the effect of optimizing all working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

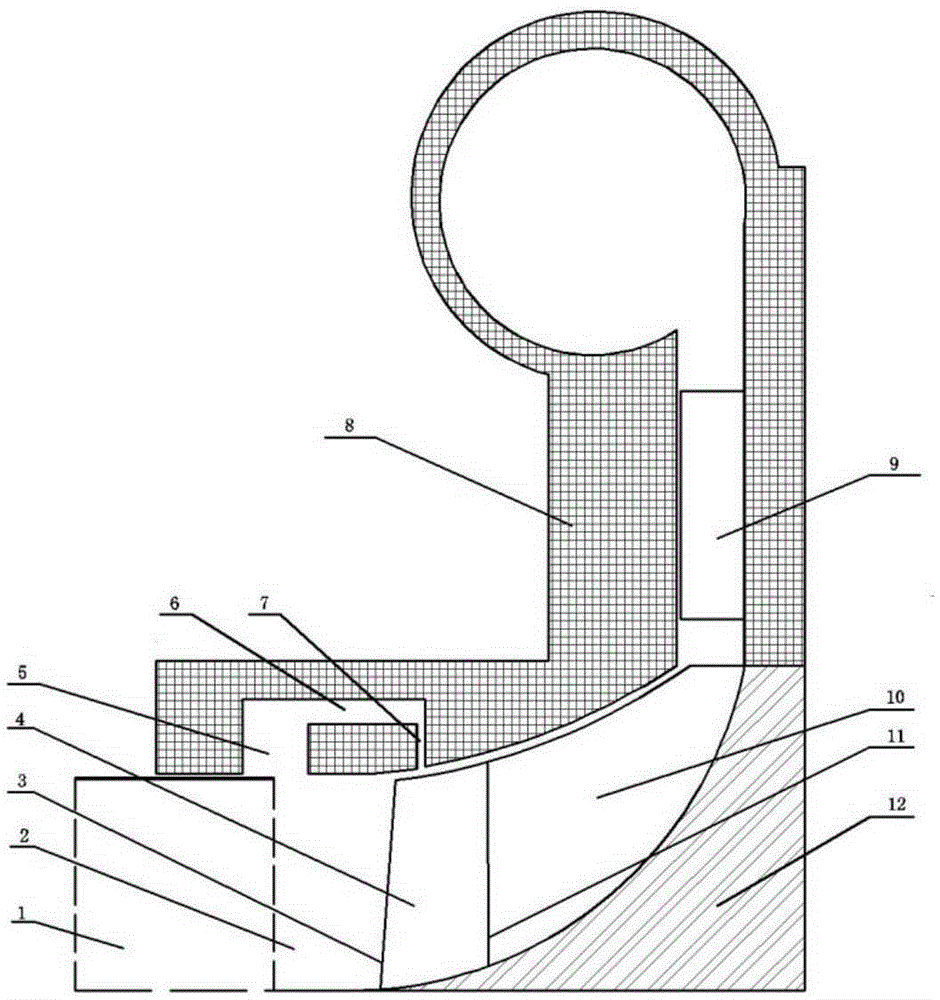

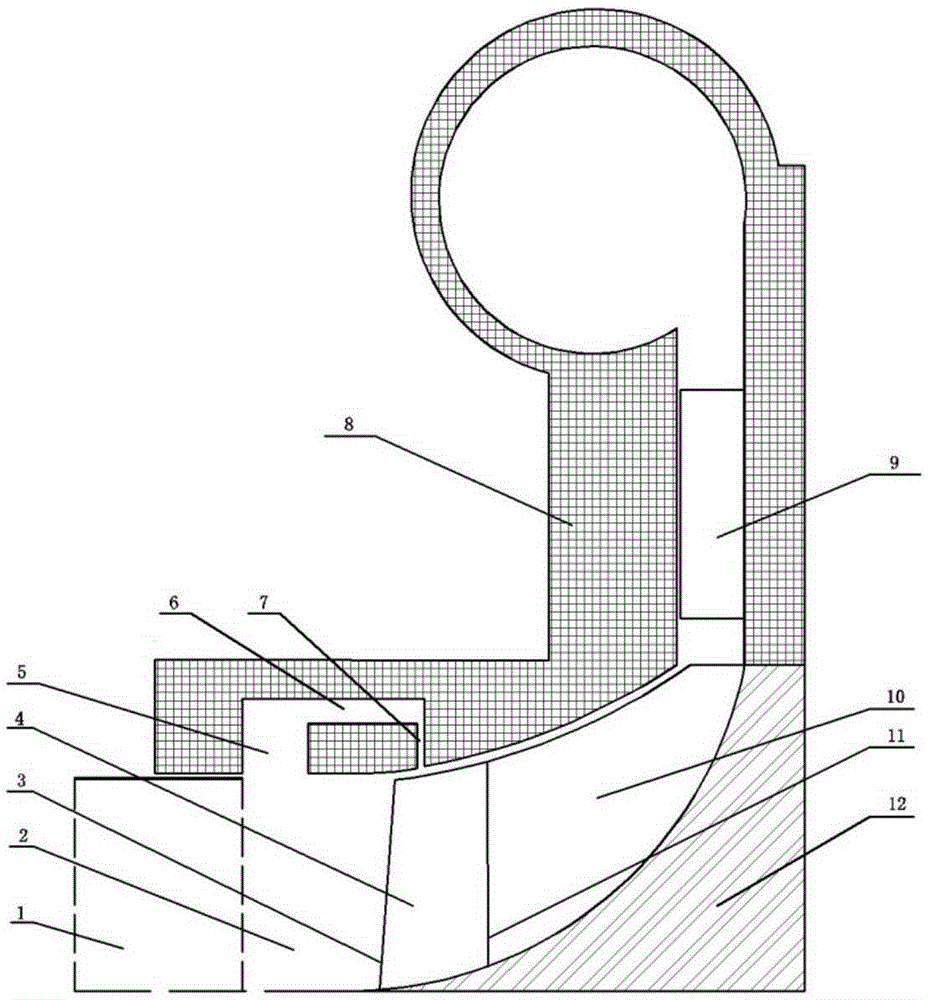

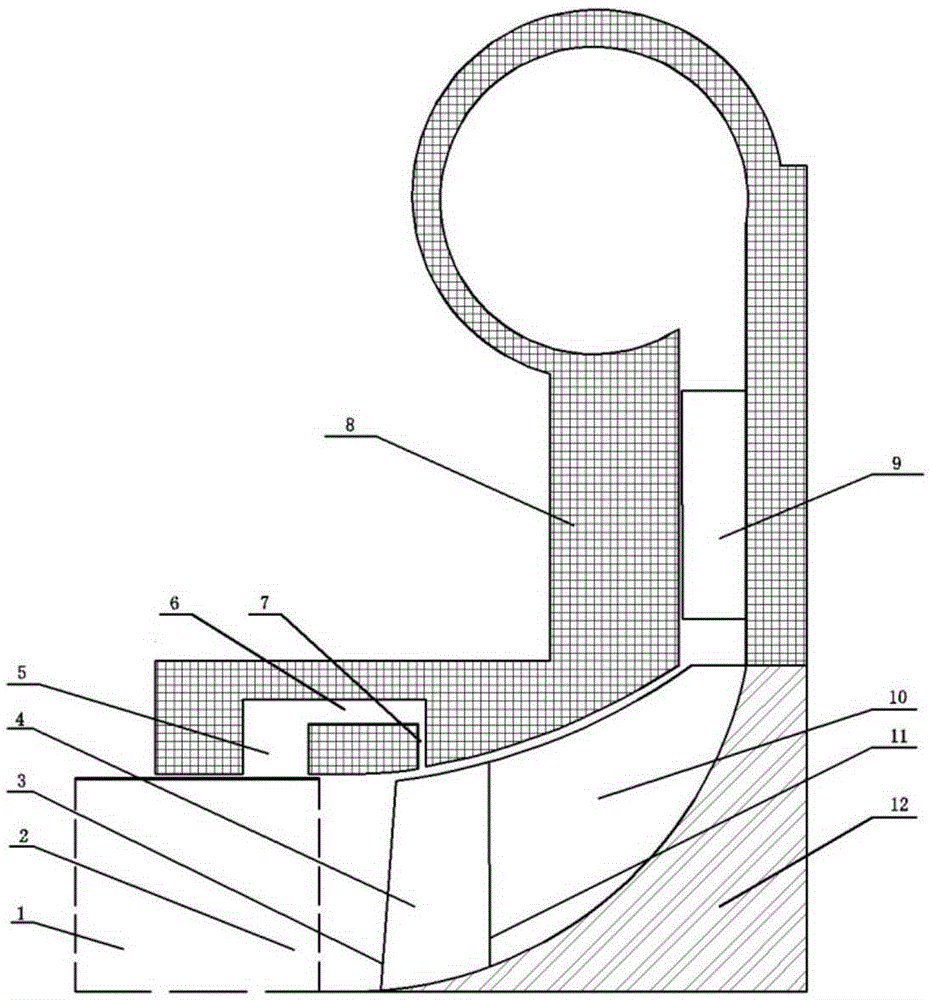

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0017] combine Figure 1-5 , The present invention is a novel variable geometric size centrifugal compressor bleed air recirculation structure, including compressor volute, bleed air recirculation channel, compressor inlet channel and inlet sliding sleeve. Its main feature is that the sliding sleeve 1 at the inlet 2 of the compressor can change the size of the outlet 6 of the bleed air recirculation passage backflow tank to change the air return flow of the bleed air recirculation passage. The suction groove 7 of the bleed air recirculation passage is located between the leading edge 3 of the main blade and the leading edge 11 of the splitter blade, the return groove 5 of the bleed air recirculation passage is located outside the outer edge of the main blade, and the sliding sleeve in the compressor inlet passage 1 Installed in the compressor inlet 2, the change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com