Hydraulic control system of ocean platform hoisting mechanism

A technology of hydraulic control system and lifting mechanism, which is applied in the direction of mechanical equipment, fluid pressure actuators, servo motors, etc. It can solve the problems of large impact of system pipelines and failure to meet the explosion-proof requirements of ships or offshore platforms, and achieve maintenance and repair Simplicity, design efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

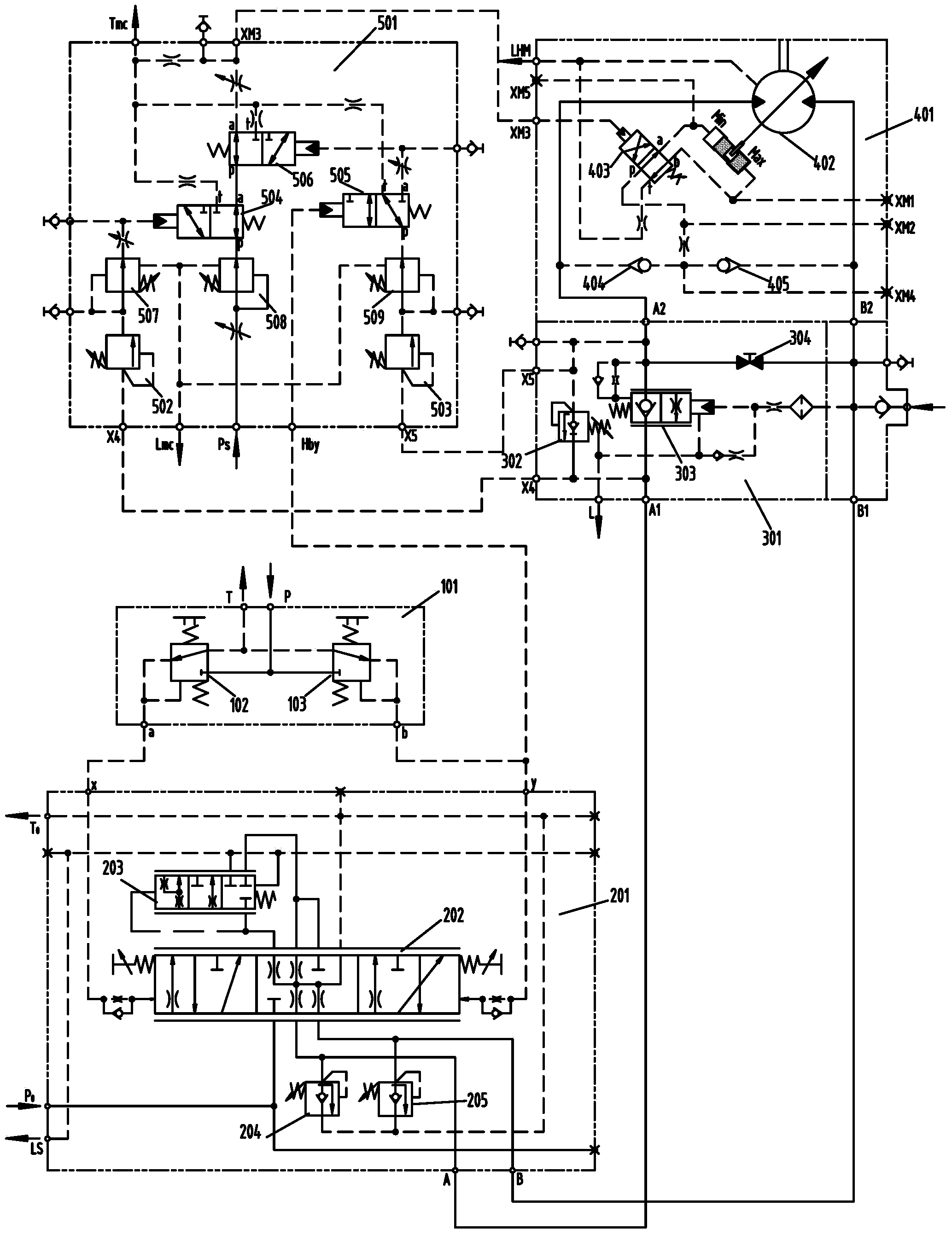

[0024] see figure 1 , the embodiment of the present invention provides a hydraulic control system for the lifting mechanism of the offshore platform, which is suitable for controlling the variable displacement hydraulic motor of the lifting mechanism of the offshore platform. The system includes: a manual pilot control valve group 101, a hydraulic control reversing main valve group 201 and balance valve group 301, the first oil outlet a and the second oil outlet b of the manual pilot control valve group 101 are respectively connected to the first control oil port x and the second control oil port x of the hydraulic control reversing main valve group 201 Port y, the first oil outlet A and the second oil outlet B of the hydraulic control reversing main valve group 201 are respectively connected to the ascending chamber and descending chamber of the variable displacement hydraulic motor through the balance valve group 301, and the system also includes hydraulic variable Control v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com