A pressure-holding hydraulic system with multi-stage braking function

A hydraulic system and two-stage braking technology, which is applied in the field of pressure-holding hydraulic systems and hydraulic pressure-holding devices, can solve the problems that the pressure-holding hydraulic device cannot realize multi-stage braking operation and the safety hazards of the pressure-holding hydraulic device, and achieve Compact structure, extended oil change interval, and less heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

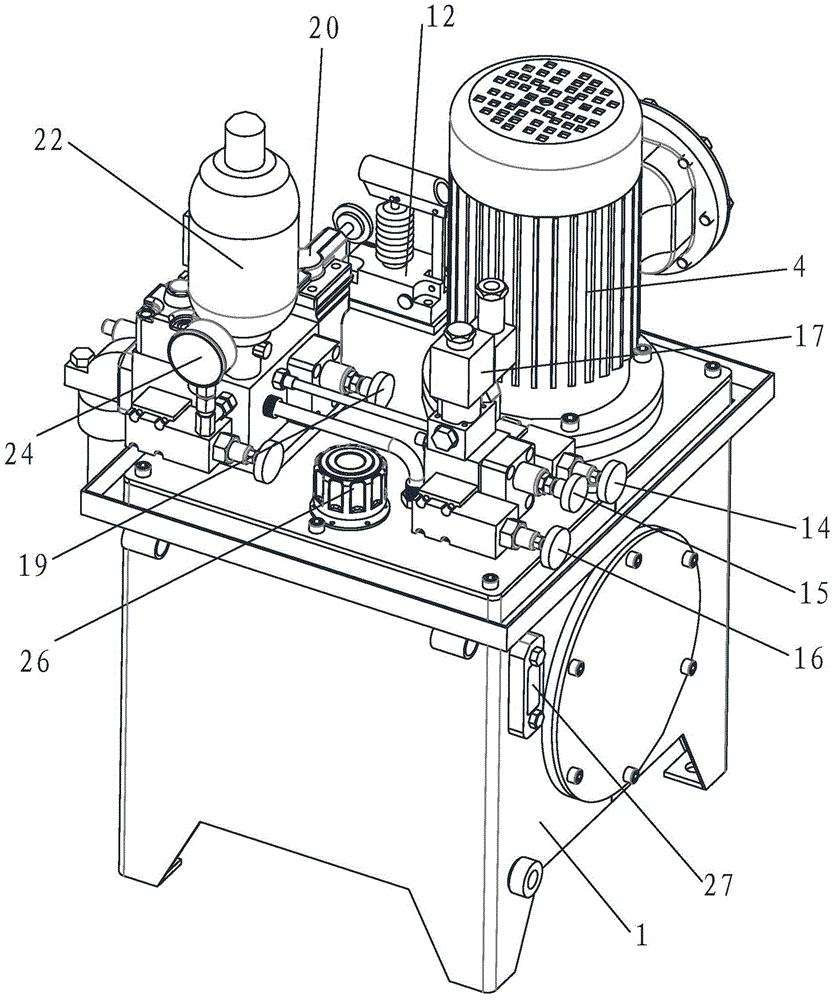

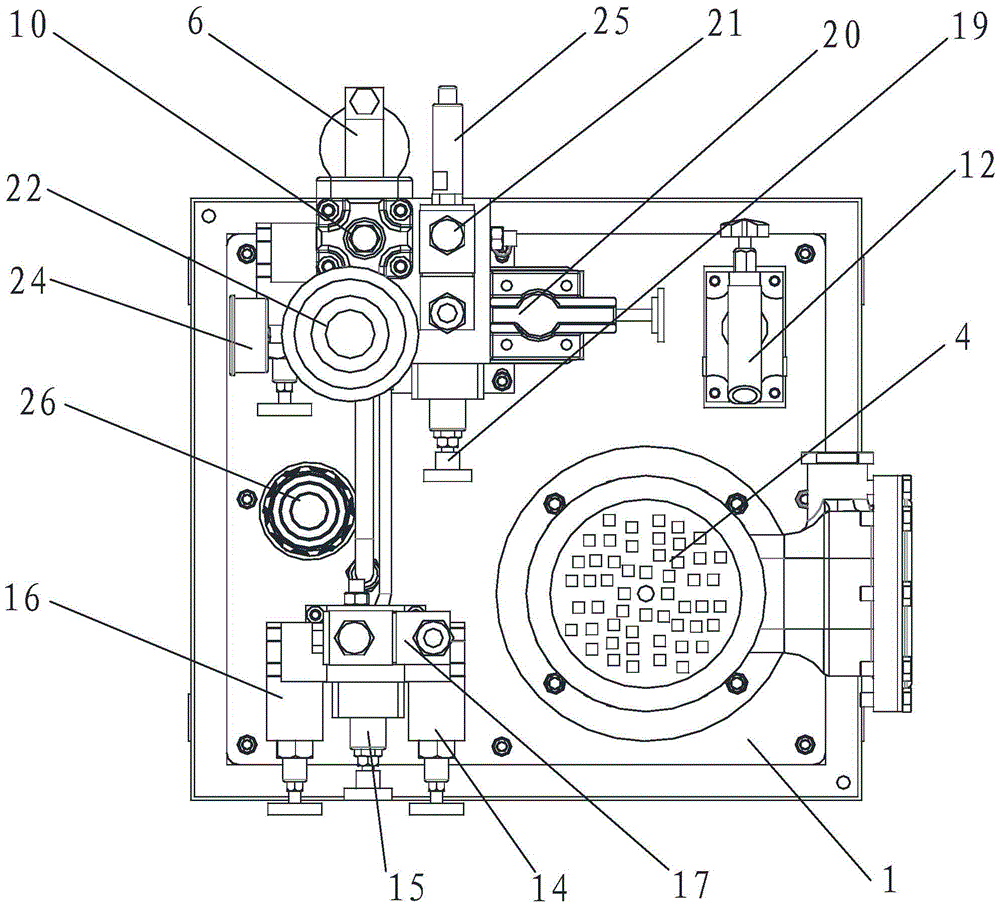

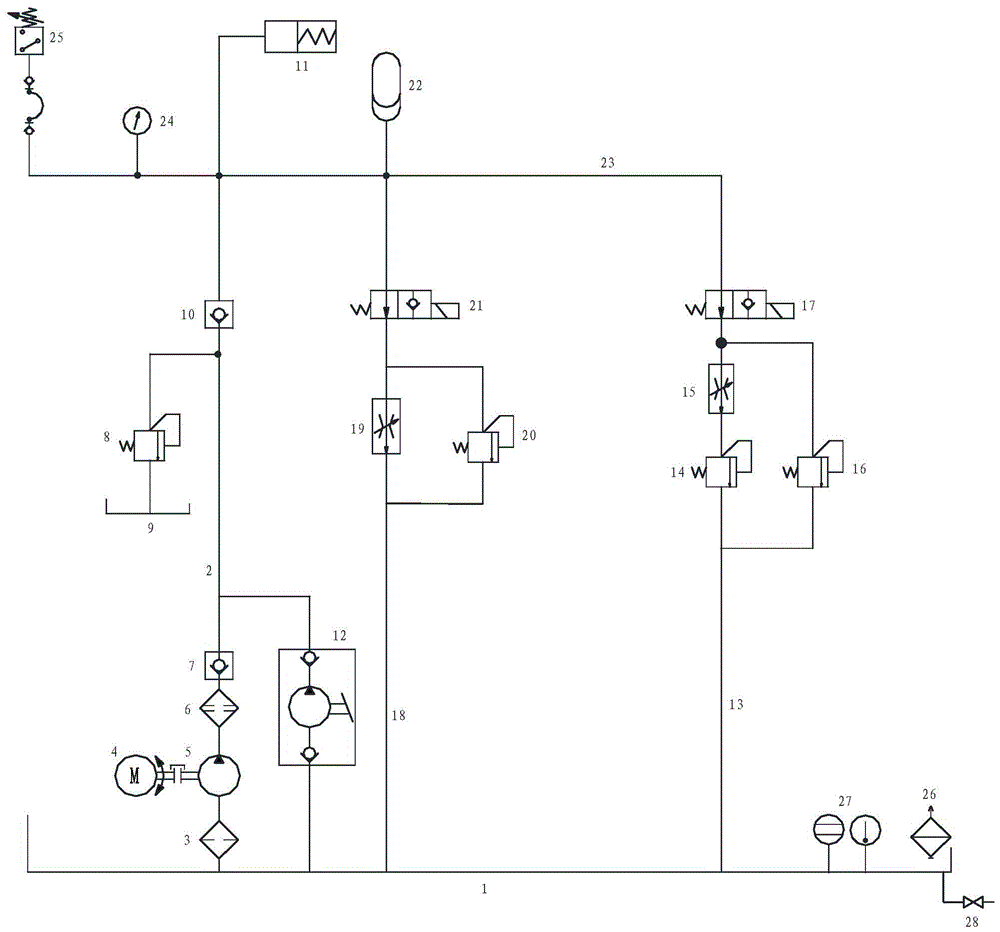

[0024] Such as figure 1 , 2 As shown in and 3, the pressure maintaining hydraulic system with multi-stage braking function includes a fuel tank 1, which is connected with an oil supply oil circuit 2, a primary brake oil circuit 13 and a secondary brake oil circuit 18.

[0025] Oil suction filter 3, gear pump 5, high pressure filter 6, first one-way valve 7, second one-way valve 10 and oil cylinder 11 are connected in series on oil supply circuit 2, wherein gear pump 5 is connected by motor 4 . The first one-way valve 7 is a pipe-type one-way valve; the second one-way valve 10 is a right-angle one-way valve.

[0026] A manual pump 12 is also connected to the oil supply circuit 2 , and the manual pump 12 is connected in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com