High-precision air floatation vertical adjusting mechanism based on differential measurement

An adjustment mechanism and differential measurement technology, which is applied in the direction of pressure difference measurement between multiple valves, measurement devices, and fluid pressure measurement, can solve the problem of excessive pressure sensor range, nonlinearity and deviation increase, and accuracy change. Poor problems, to achieve high measurement accuracy and good experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited to this. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the technical solution of the present invention. in the scope of protection.

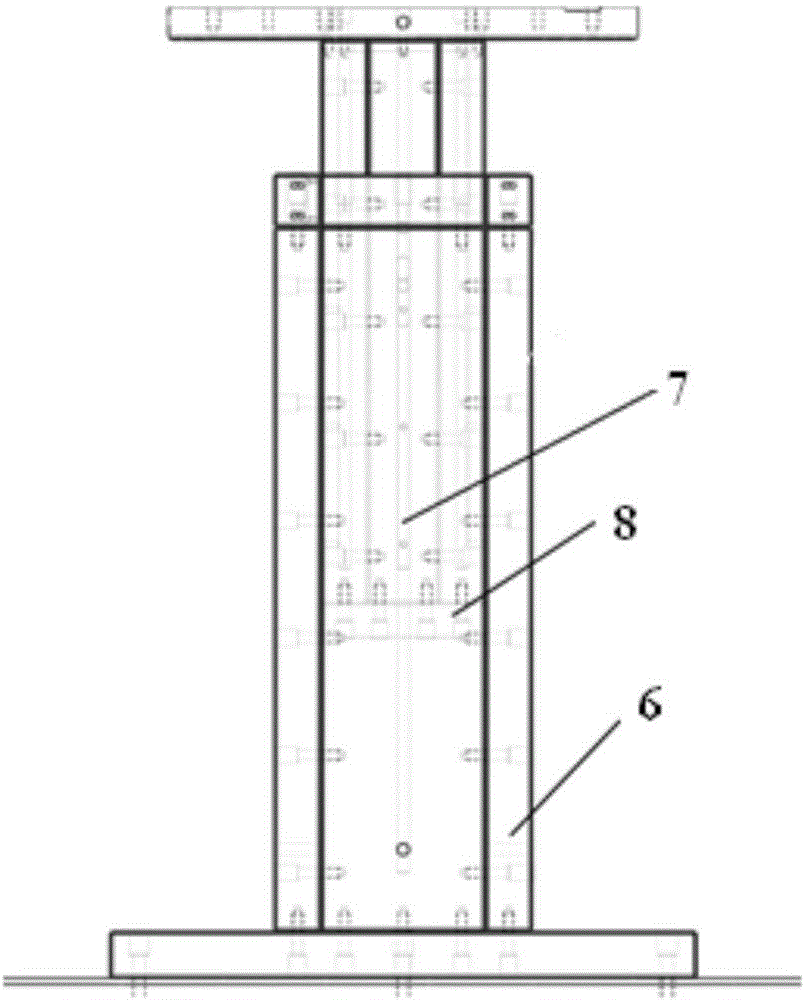

[0015] The invention provides a high-precision air bearing vertical adjustment mechanism based on differential measurement, such as figure 1 As shown, the vertical movement mechanism 1 is a vertically moving air bearing shaft composed of two important parts: the column type vertical air bearing outer cover 6 and the vertical air bearing inner sleeve 8; A number of nozzles are installed, and there is a vertical air chamber 2 between the vertical air bearing outer sleeve 6 and the vertical air bearing inner sleeve 8 to balance the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com