A preparation method of a low dielectric constant composite film containing nanopores

A low dielectric constant, composite thin film technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of mechanical property degradation, limit the application of low-k thin films, and deteriorate the thermal stability of thin films, etc., to achieve excellent mechanical properties performance, good insulation performance, and the effect of low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

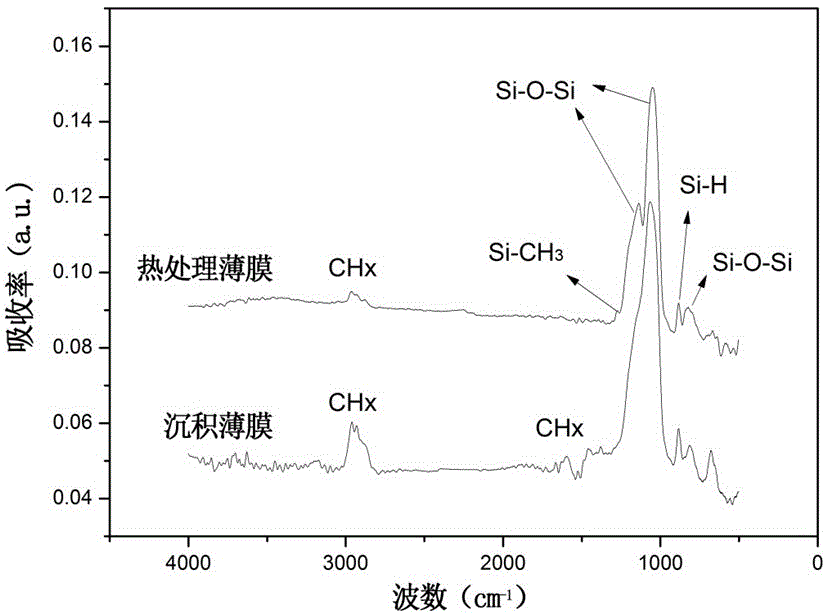

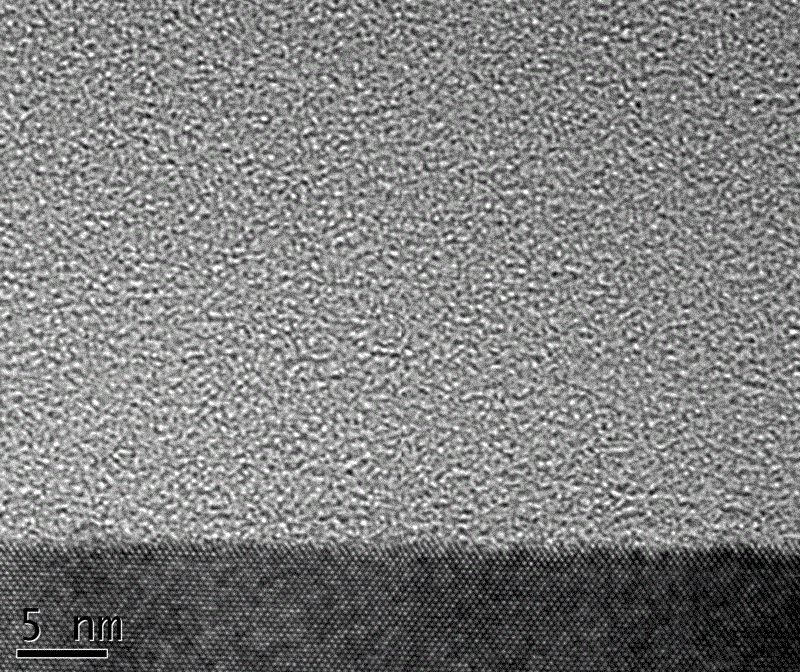

[0018] The substrate temperature was set at 200 °C, the working pressure in the reaction chamber was 3 Torr, the deposition power was 300 W; the mass ratio of TEOS and LIMO was 1:1, and the vaporization temperatures were 160 °C and 100 °C, respectively; helium was used as the carrier gas , the flow rates were 2000 sccm and 5000 sccm, and the inorganic-organic composite thin film was deposited. The deposited film is thermally annealed at different temperatures in an argon (Ar) atmosphere, the pressure is less than 0.3 Torr, and the annealing time is 1 hour.

[0019] Thin film performance measurement: The film thickness and refractive index are measured by ellipsometer, the measurement wavelength range is 250 nm~800 nm, and the Cauthy model is used for fitting. In order to measure the electrical properties of the above-mentioned thin film, the present invention uses a low-resistivity silicon wafer (resistivity 0.001~0.005 Ω·cm) as the substrate, and uses electron beam evaporated...

Embodiment 2

[0024] The substrate temperature was set at 200 °C, the working pressure in the reaction chamber was 3 Torr, and the deposition power was 300 W; different mass ratios of TOES and LIMO were used to obtain a clean low-resistivity silicon wafer (resistivity 0.001-0.005 Ω• cm) as the substrate, a series of inorganic-organic composite films were deposited, and in nitrogen (N 2 ) atmosphere for thermal annealing, the pressure is about one atmosphere, the annealing temperature is 450 °C, and the annealing time is 1.5 hours. As shown in Table 2, the refractive index of the obtained films ranged from 1.364 to 1.369, the Young's modulus ranged from 6.65 GPa to 8.79 GPa, and the hardness ranged from 0.59 GPa to 0.92 GPa. The electrical properties of the obtained film were tested at 100°C, the k value was 2.60~2.75, and the leakage current density at 1 MV / cm was all at 10 -9 A / cm 2 Magnitude.

[0025] Table 2

[0026] .

Embodiment 3

[0028] Set the substrate temperature at 200 °C, the working pressure in the reaction chamber at 3 Torr, the mass ratio of TEOS and LIMO at 1:1, and use a clean low-resistivity silicon wafer (0.001-0.005 Ω cm) as the substrate , change the deposition power (respectively 350 W, 450 W, 550 W), and deposit a series of thin films. Then, the obtained thin film was placed in an Ar atmosphere for thermal annealing treatment, the gas pressure was less than 0.3 Torr, the annealing temperature was 425° C., and the annealing time was 4 hours. The electrical properties of the heat-treated film are shown in Table 3, and the test temperature is room temperature. As the PECVD RF power increased from 350 W to 550 W, the dielectric constant of the obtained film increased from 2.71 to 2.90, and the leakage current density at 1 MV / cm field strength was located at 8.06×10 -9 A / cm 2 ~1.23×10 -8 A / cm 2 within range.

[0029] table 3

[0030] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com