Knit With Zones Without Barbs, Method Of Making Same And Prostheses Obtained Therefrom

A braiding and barb technology, applied in the field of patch braiding, can solve the problems of cumbersome and complicated processes, and achieve the effect of optimizing the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The following knitted fabrics according to the invention were made on a warp knitting machine:

[0039] Braid A: has the following diagrams according to the ISO11676 standard:

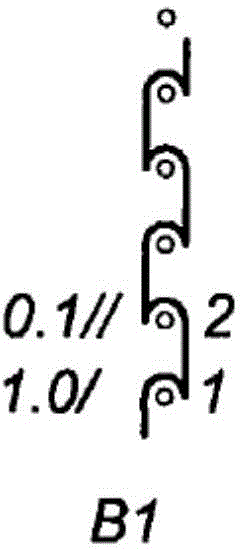

[0040] - Comb B1: 1.0 / 0.1 / /

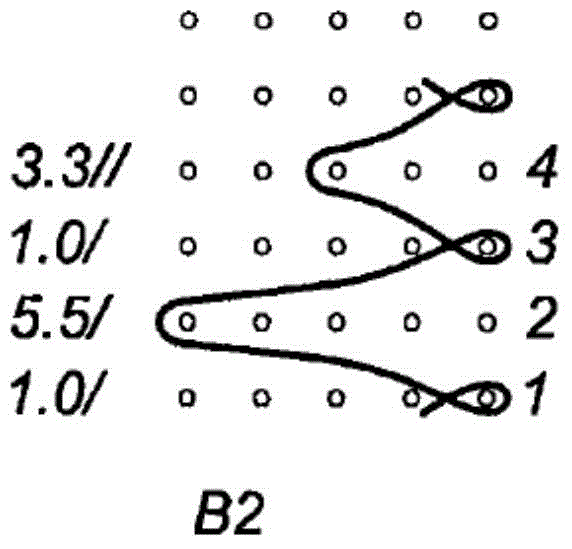

[0041] - Comb B2: 1.0 / 5.5 / 1.0 / 3.3 / /

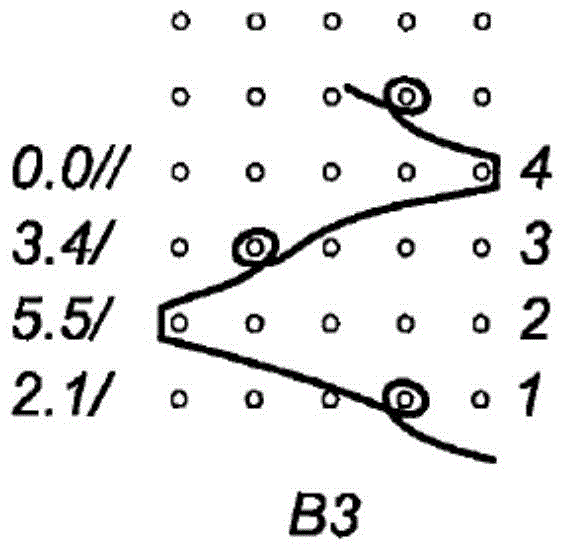

[0042] - Comb B3: 2.1 / 5.5 / 3.4 / 0.0 / /

[0043] The individual diagrams of bars B1, B2 and B3 are shown in Figures 1A to 1C .

[0044] Alternatively, the illustration of bar B2 can be replaced by the following:

[0045] 1.0 / 7.7 / 6.6 / 7.7 / /

[0046] Bars B1 and B2 were each made of a monofilament yarn with a diameter of 0.08 mm made of polyethylene terephthalate (PET) purchased from the company SIDER ARC at 1 full across the width of the braiding machine. , 1 empty continuous threading. The melting point of the monofilament yarn made of polyethylene terephthalate (PET) was 258°C.

[0047] The barb-producing bar B3 was continuously threaded with a 0.15 mm diameter heat-fusible monofilament yarn made of polylactic acid over the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com