Direct jet type slurry spraying granulation drier

A technology of spray granulation and drying machine, which is applied in the direction of fertilizer form, liquid separation into beads and granulation, fertilizer mixture, etc., which can solve the problems of low production quality, low degree of automation, and weak system, and achieve high particle quality. Prominent, low-cost, systematic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

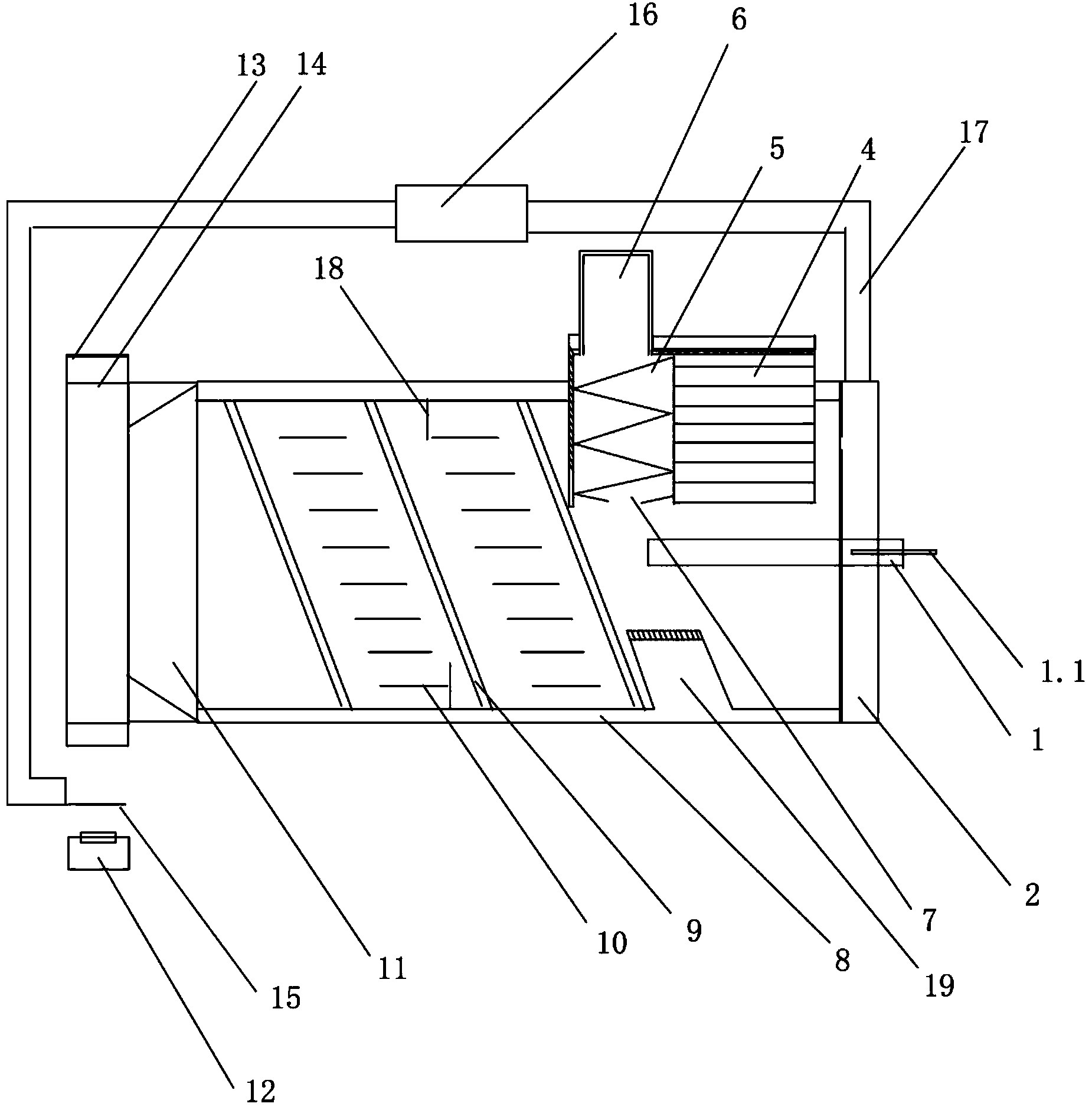

[0021] Such as figure 1 As shown, the direct flushing spraying granulation dryer includes a drying body 8, and a feeding bin 2 is provided on the side of the drying body 8. High-pressure air pipe 1.1, baffle plate 18, anti-material spiral body 9 and material plate 10 are provided on the inner wall of the drying body; a grading cone 11 is provided at the tail of the drying body 8, and a hot air system 3 is provided at the top of the drying body 8, and the hot air system 3 includes Vertically downward fine material injection port 6, the lower part of the fine material injection port 6 is provided with a screw chamber 5, the lower part of the screw chamber 5 is provided with a fine material outlet 7, and the side part of the spiral chamber 5 is provided with a heat blower that can blow air to the spiral chamber. The fan 4 and the fine material outlet 7 are facing the granulation spray gun 1.

[0022] The rear position of the grading cone 11 is also provided with a rotary screen,...

Embodiment 2

[0025] In this embodiment, the difference from embodiment 1 is that the sharpness of the blower 1 is 0.5 times the power of the hot air blower, and the rest of the working principles are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com