Synthesis of novel coal flotation agent

A flotation agent and coal technology, applied in flotation, solid separation and other directions, can solve problems such as single flotation function, and achieve the effects of high flotation efficiency, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

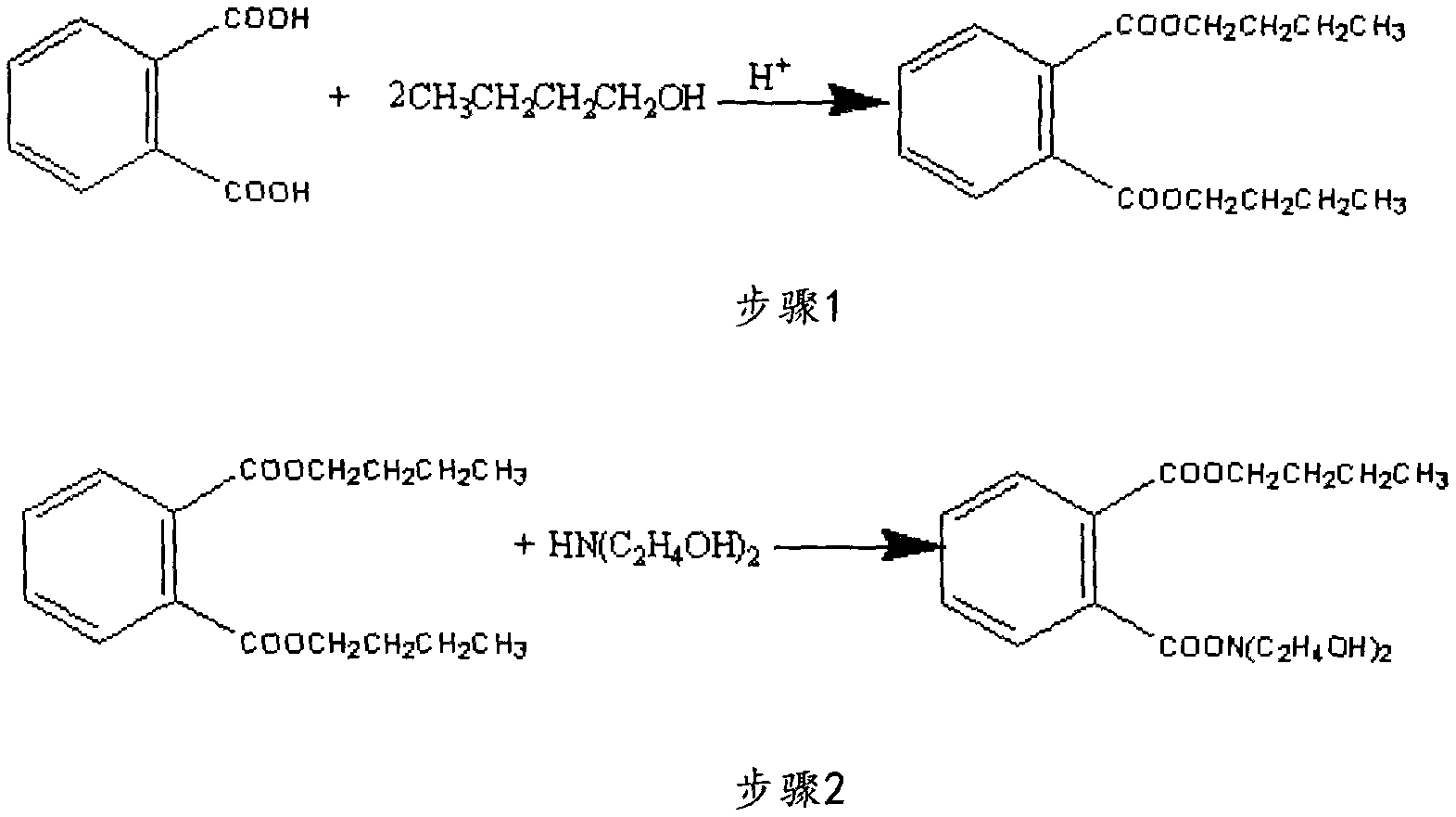

Method used

Image

Examples

Embodiment 1

[0022] Add 24g of phthalic anhydride, 50mL of n-butanol and several zeolites into a dry 250mL three-necked flask, and slowly add 0.4mL of concentrated sulfuric acid dropwise under shaking. Slowly raise the temperature to 120°C to make the reaction mixture boil slightly. After about 15 minutes, the solid in the flask completely disappears. At this time, the azeotrope of n-butanol and water gradually evaporates, and the small water droplets at the bottom of the water separator gradually flow out after condensation. When the bottom of the water separator is reached, stop heating when the water volume no longer increases. After the reaction solution was cooled, the reaction mixture was poured into a separatory funnel, neutralized with 5% sodium carbonate solution until the organic layer was neutral, and the separated oil was dried with anhydrous magnesium sulfate until clear. The liquid separated by filtration was evaporated under reduced pressure to remove excess n-butanol and a ...

Embodiment 2

[0025] Add 24g of phthalic anhydride, 80mL of n-butanol and several zeolites into a dry 250mL three-neck flask, and slowly add 1.4mL of concentrated sulfuric acid dropwise under shaking. Slowly raise the temperature to 160°C to slightly boil the reaction mixture. After about 30 minutes, the solids in the flask disappear completely. At this time, the azeotrope of n-butanol and water gradually evaporates, and the small water droplets condensed at the bottom of the water separator gradually flow out. When the bottom of the water separator is reached, stop heating when the water volume no longer increases. After the reaction solution was cooled, the reaction mixture was poured into a separatory funnel, neutralized with 1% sodium carbonate solution until the organic layer was neutral, and the separated oil was dried with anhydrous magnesium sulfate until clear. The liquid separated by filtration was evaporated under reduced pressure to remove excess n-butanol and a small amount of ...

Embodiment 3

[0028] Involving the application process of the present invention:

[0029] Get 100g of coal slime, add 400ml of water to it and stir, add 0.01g of the flotation agent prepared in Example 1 to it after standing still and feed air for 3min, leave standstill for 30min, significant stratification occurs in coal slime, last time it was suspended Coal, the lower layer is mud, and the flotation efficiency of coal slime reaches 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com