Method for cutting sealing head for automatic trepanning

A cutting method and automatic technology, applied in welding/cutting auxiliary equipment, auxiliary devices, manipulators, etc., can solve the problems such as the inability to guarantee the accurate trajectory and position of the intersecting line, affecting the appearance of the container and product quality, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0026] Let me explain that the following workpiece in the present invention is the head.

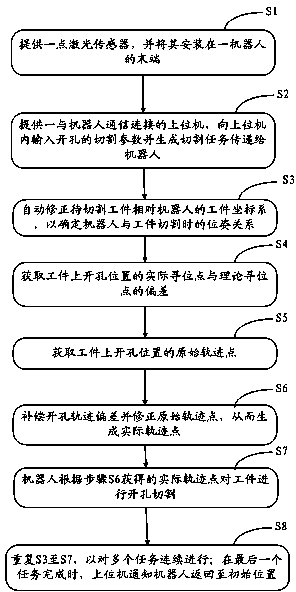

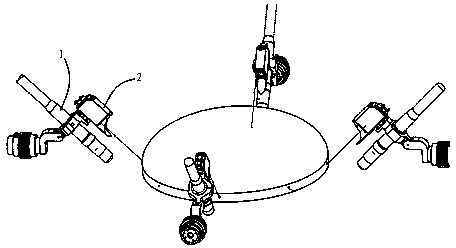

[0027] Please refer to figure 1 , figure 2 As shown, in a specific embodiment of the present invention, the cutting method for automatic opening of the head includes the following steps:

[0028] S1, provide a little laser sensor 2, and install it on the end of a robot;

[0029] S2. Provide a host computer connected to the robot in communication, input the cutting parameters of the opening in the host computer and generate a cutting task to pass to the robot; the robot and the host computer described in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com