A water purification system and method with concentrated water production and backwashing functions

A water purification system and backwashing technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The problem of poor flushing effect, etc., achieves the effect of excellent filtering function, easy application and promotion, and significant beneficial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

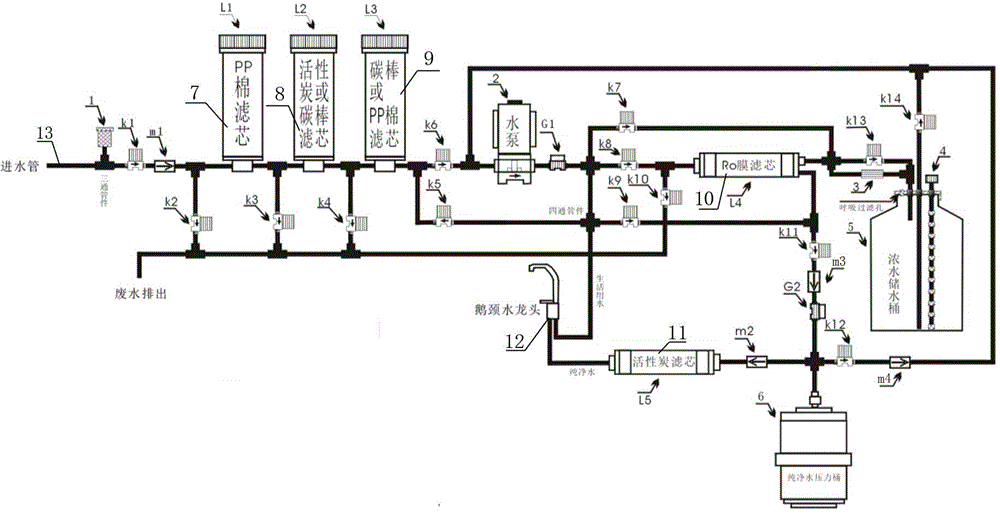

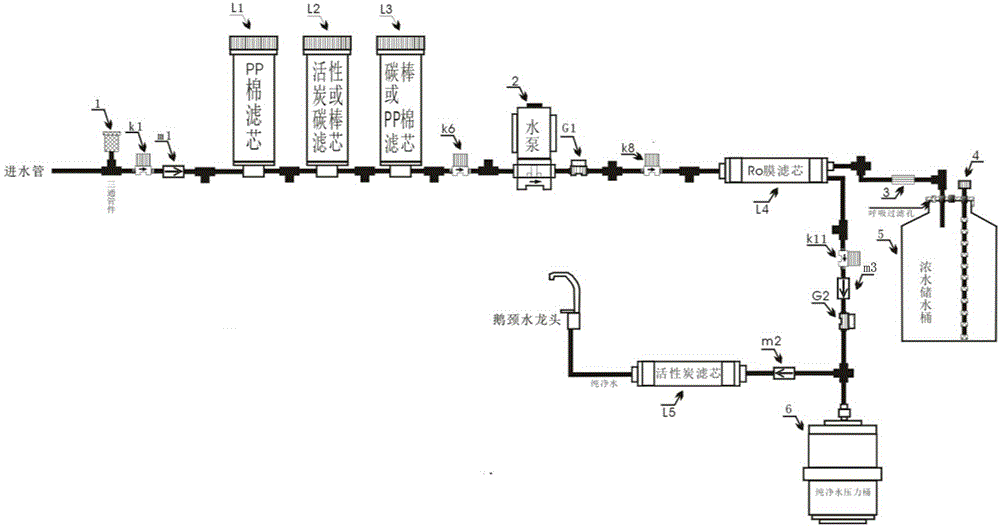

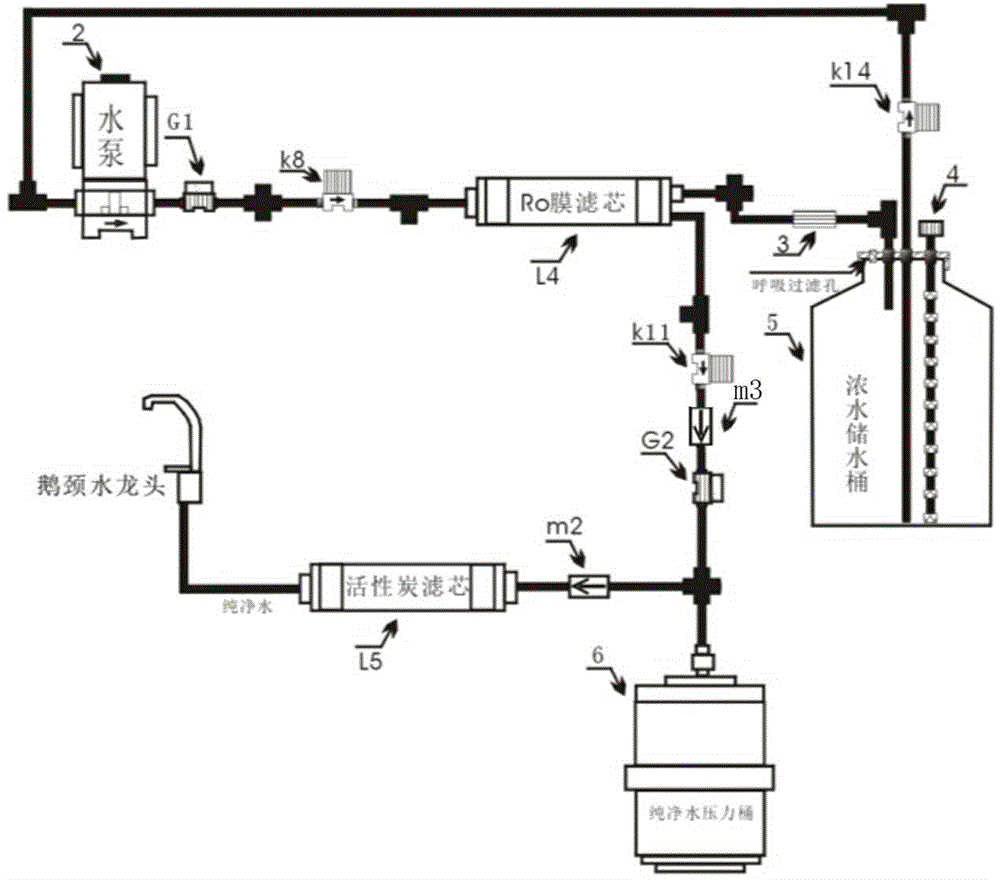

[0028] Such as figure 1 As shown, the principle diagram of the water purification system with concentrated water production and backwashing functions of the present invention is given, which includes a raw water inlet pipe 13, a low pressure switch 1, a water pump 2, a waste water proportional regulator 3, a water level sensor 4, Concentrated water storage tank 5, pure water pressure tank 6, L1 filter element 7, L2 filter element 8, L3 filter element 9, RO membrane filter element 10, activated carbon filter element L5 (11), water dispenser 12, raw water inlet pipe 13, electric control valve k1~ k14, one-way check valves (m1, m2, m3, m4), high-pressure switches G1 and G2, and the circuit part; the pipelines from the raw water inlet pipe 13 to the water inlet of the L1 filter element 7 are provided with low-pressure switches 1, The electric control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com