Regenerated OGFC (Open-graded Friction Courses) mixed material and preparation method thereof

A technology of mixed material and mineral material, which is applied in the field of recycled OGFC mixed material and its preparation, can solve the problems of not using old material to restore, failing to achieve the regeneration of old material resources, etc., and achieve the effect of accurate results, low cost and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

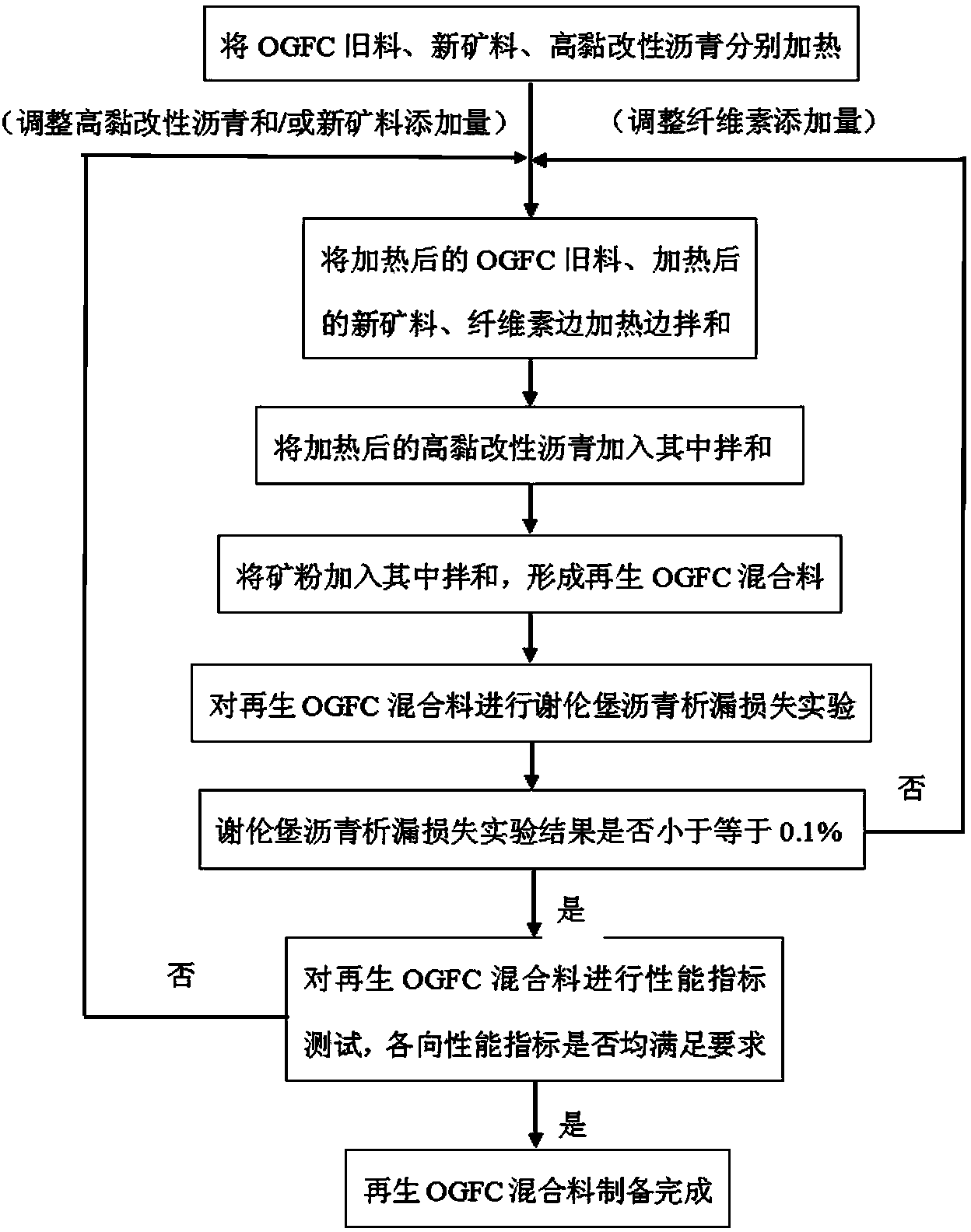

Method used

Image

Examples

Embodiment 1

[0042] Take the recycled OGFC-13 mixture and its preparation method as an example.

[0043] 1. Performance test of raw materials

[0044] The amount of old materials in the recycled OGFC-13 mixture is 20%, and the old materials contain mineral materials and high-viscosity asphalt; the cellulose is lignin fiber, and the amount is 0.3%; the mineral powder is lime powder, and the amount 6%; the dosage of high-viscosity modified asphalt is 6%; the new mineral materials are basalt and machine-made sand; the initial asphalt ratio is 6.5%.

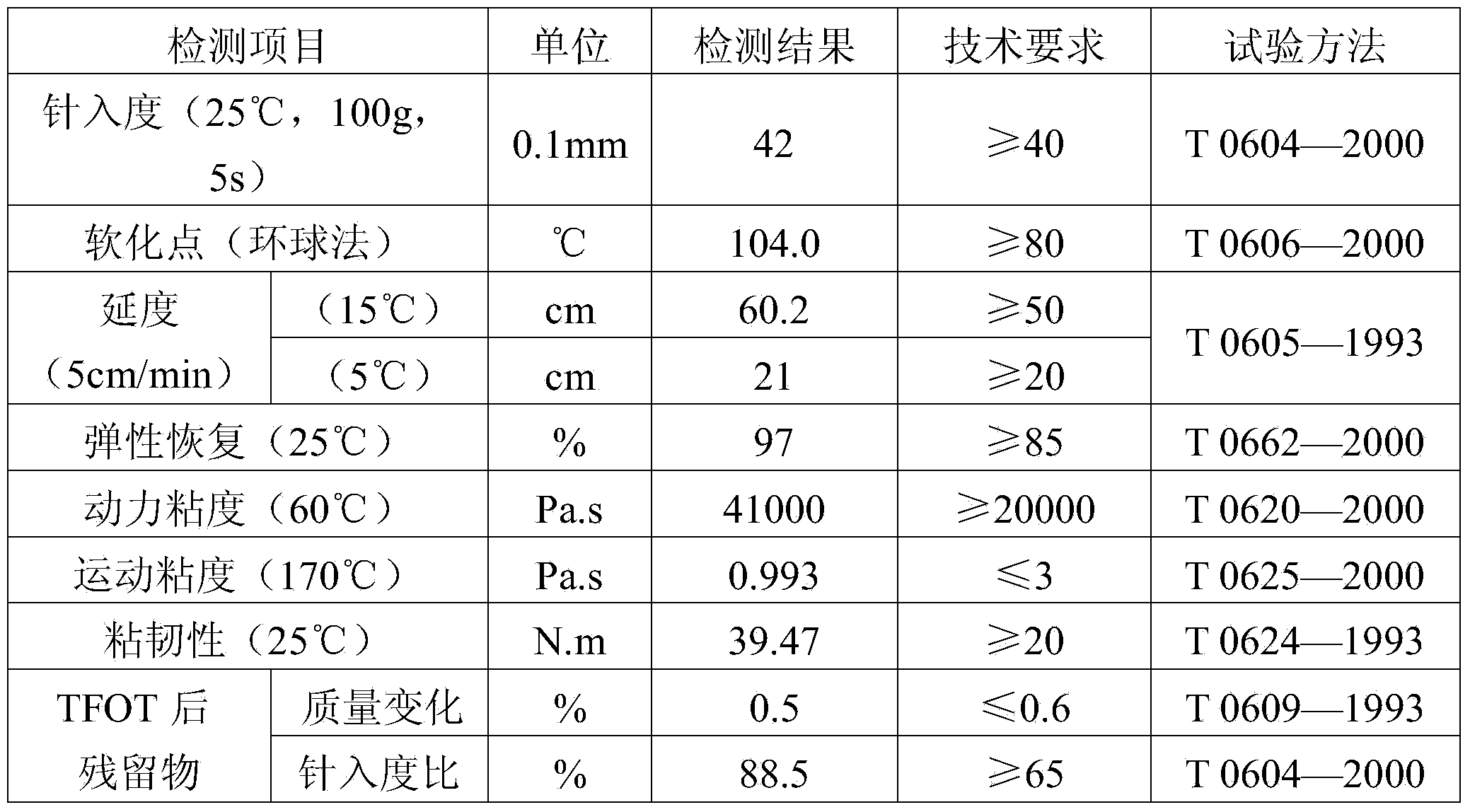

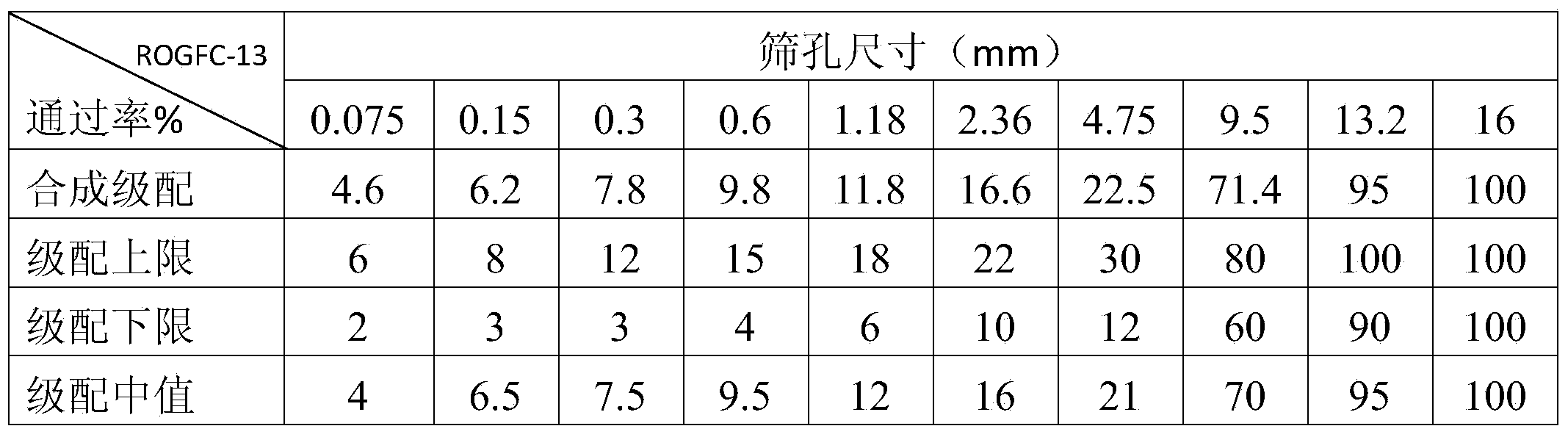

[0045] The performance test results of high-viscosity modified asphalt are shown in Table 1, the test results of lignin fiber properties are shown in Table 2, and the synthesis gradation of recycled OGFC-13 is shown in Table 3.

[0046] Table 1: Performance test results of high viscosity modified asphalt

[0047]

[0048] Table 2: Test results of lignin fiber properties

[0049] indicators

unit

test results

skills requ...

Embodiment 2

[0065] Take the recycled OGFC-20 mixture and its preparation method as an example.

[0066] 1. Performance test of raw materials

[0067] The amount of old materials in the recycled OGFC-20 mixture is 15%, and the old materials contain mineral materials and high-viscosity asphalt; the cellulose is selected from lignin fiber, and the amount is 0.1%; 2%; the dosage of high-viscosity modified asphalt is 4%; andesite and machine-made sand are selected as new mineral materials; the initial asphalt ratio is 5.5%.

[0068] The performance test results of high-viscosity modified asphalt are shown in Table 1, the performance test results of lignin fiber are shown in Table 2, and the synthesis gradation of recycled OGFC-20 is shown in Table 5.

[0069] Table 5: Synthesis gradation of regenerated OGFC-20

[0070]

[0071] The properties of high-viscosity modified asphalt and lignin fiber were tested according to the industry testing standards of our country, and the test results wer...

Embodiment 3

[0089] Take the recycled OGFC-20 mixture and its preparation method as an example.

[0090] The amount of old materials in the recycled OGFC-20 mixture is 15%, and the old materials contain mineral materials and high-viscosity asphalt; the cellulose is selected from lignin fiber, and the amount is 0.1%; 2%; the dosage of high-viscosity modified asphalt is 4%; andesite and machine-made sand are selected as new mineral materials; the initial asphalt ratio is 5.5%. The performance test results of raw materials are in line with the corresponding regulations in our country's specifications.

[0091] The preparation method of the regenerated OGFC-20 mixture, the heating temperature and time, the mixing time, the leakage loss results, the performance test results of the regenerated OGFC-20 mixture and other parameters are the same as those in Example 2. Among them, the freeze-thaw splitting strength ratio is 75.2%, which does not meet the requirement of 80% or more in the performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com