Method for improving raffinate product yield of acetonitrile-process 1,3-butadiene extracting apparatus

An extraction device and butadiene technology, applied in the field of improving the yield of the raffinate product of the acetonitrile method 1,3-butadiene extraction device, can solve the problems of reducing the economic benefits of the butadiene device and downstream devices, Achieve the effect of improving operational safety and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

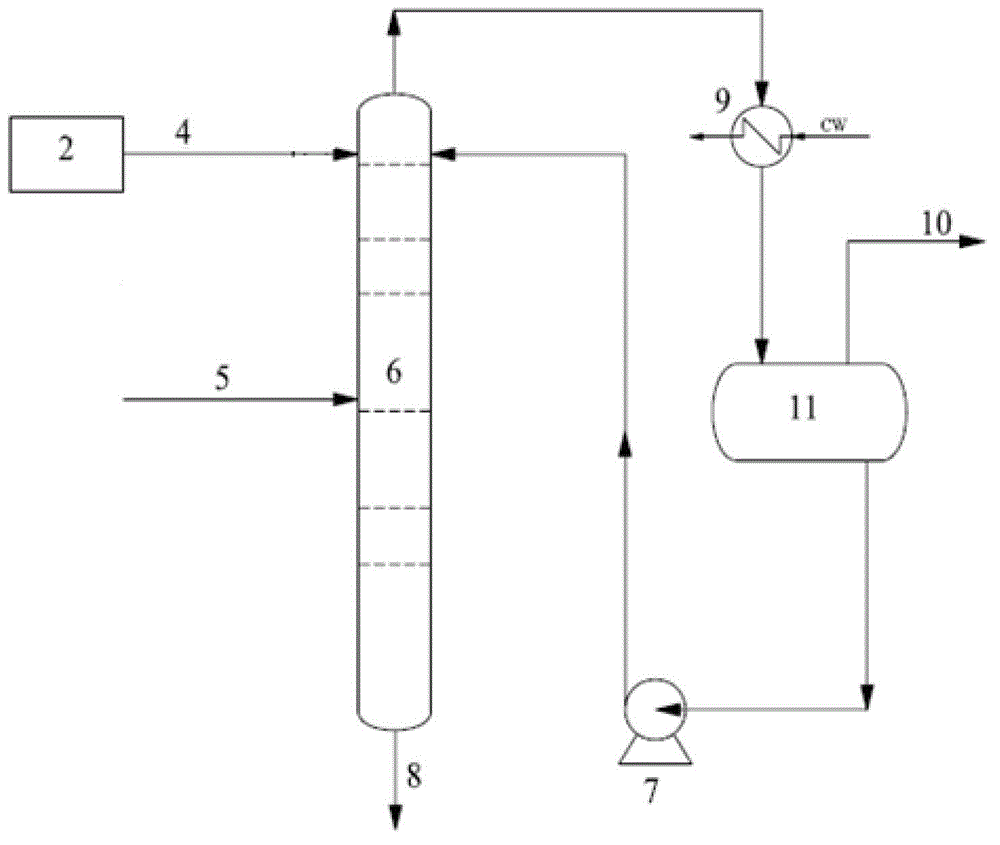

[0018] Dissolved with C 4 The acetonitrile solvent of alkynes enters the middle part of the second stripper, and introduces the remaining C of a MTBE / butene-1 unit 4 Instead of the raffinate at the top of the first extraction system, it enters the upper part of the second stripper as a dilution gas, and the C containing vinyl acetylene 4 The alkyne gas is stripped out in the alkyne flash tower, and discharged from the reflux tank after cooling to control the remaining C 4 flow such that C 4 The concentration of vinyl acetylene in alkyne gas is below 30% (by weight).

[0019] Dissolved with C 4 The acetonitrile solvent of alkynes is 36684.8kg / h, and the concentration of vinyl acetylene is 1.493wt%;

[0020] remaining C 4 It is the C of the butene-1 rectifying tower-I tower still of MTBE / butene-1 device 4 ;

[0021] The second stripper theoretical plate number is 10;

[0022] The temperature of the bottom of the second stripping column is 93.4° C., the pressure is 0.02 M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com