An anodic oxidation tank and brightening technology of strip-series aluminum alloy section bars

A technology of aluminum alloy profile and anodic oxidation tank, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., which can solve the problem of uneven surface quality of aluminum alloy profiles, unstable electrolyte heating or cooling, and difficulties in meeting consumption Consumer demand and other issues to achieve the effect of reducing the late scrap rate, reducing waste of raw materials, and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

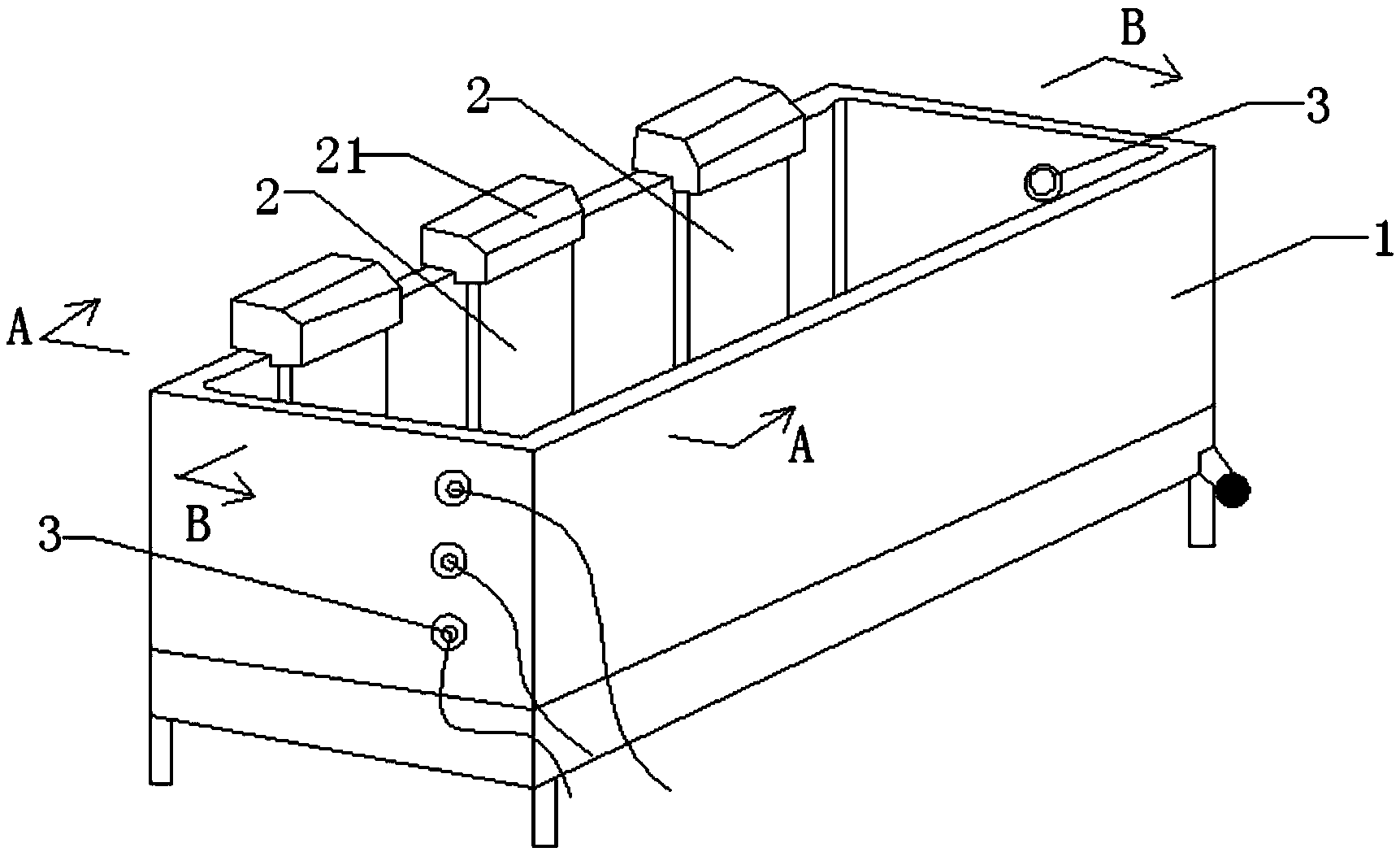

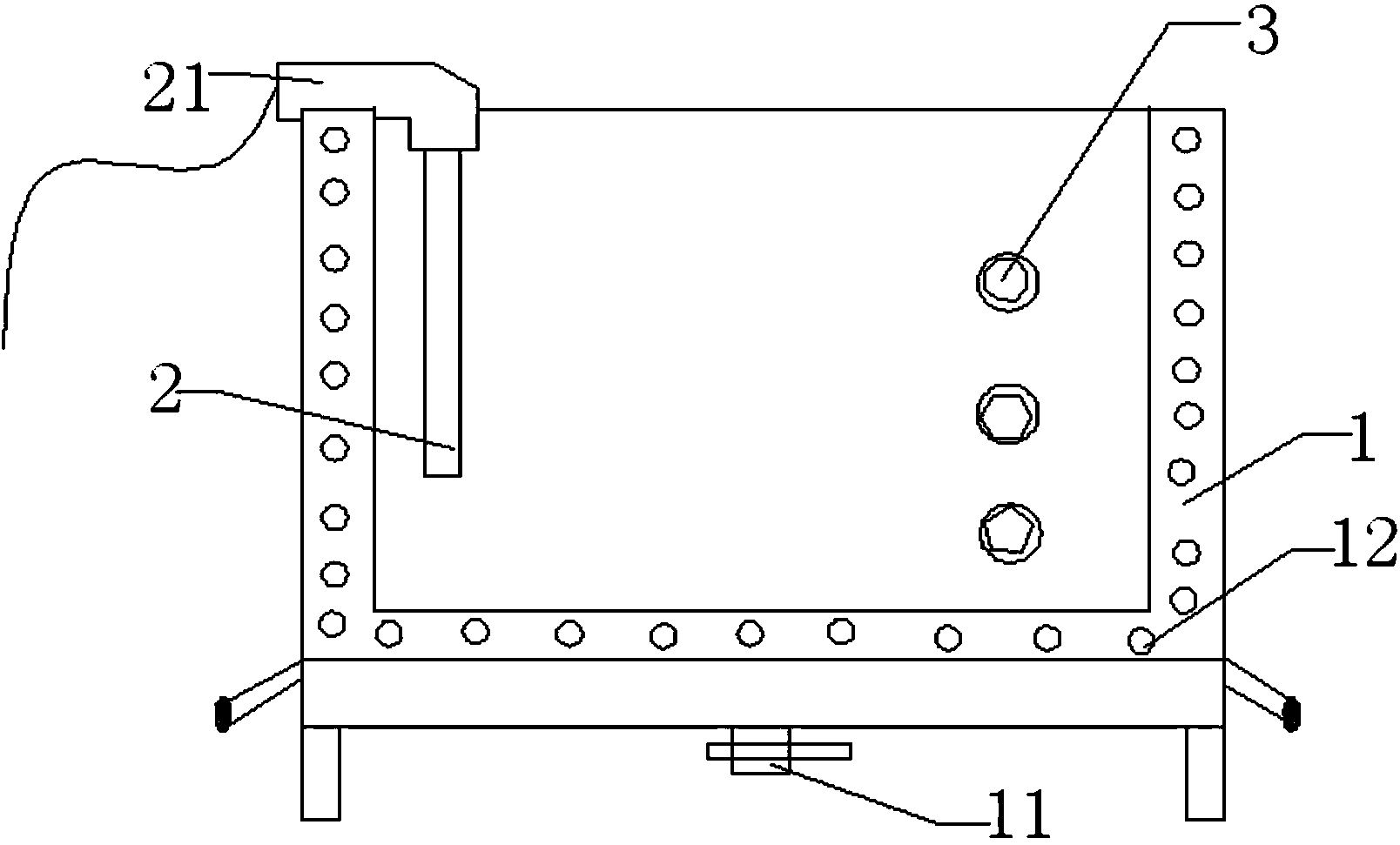

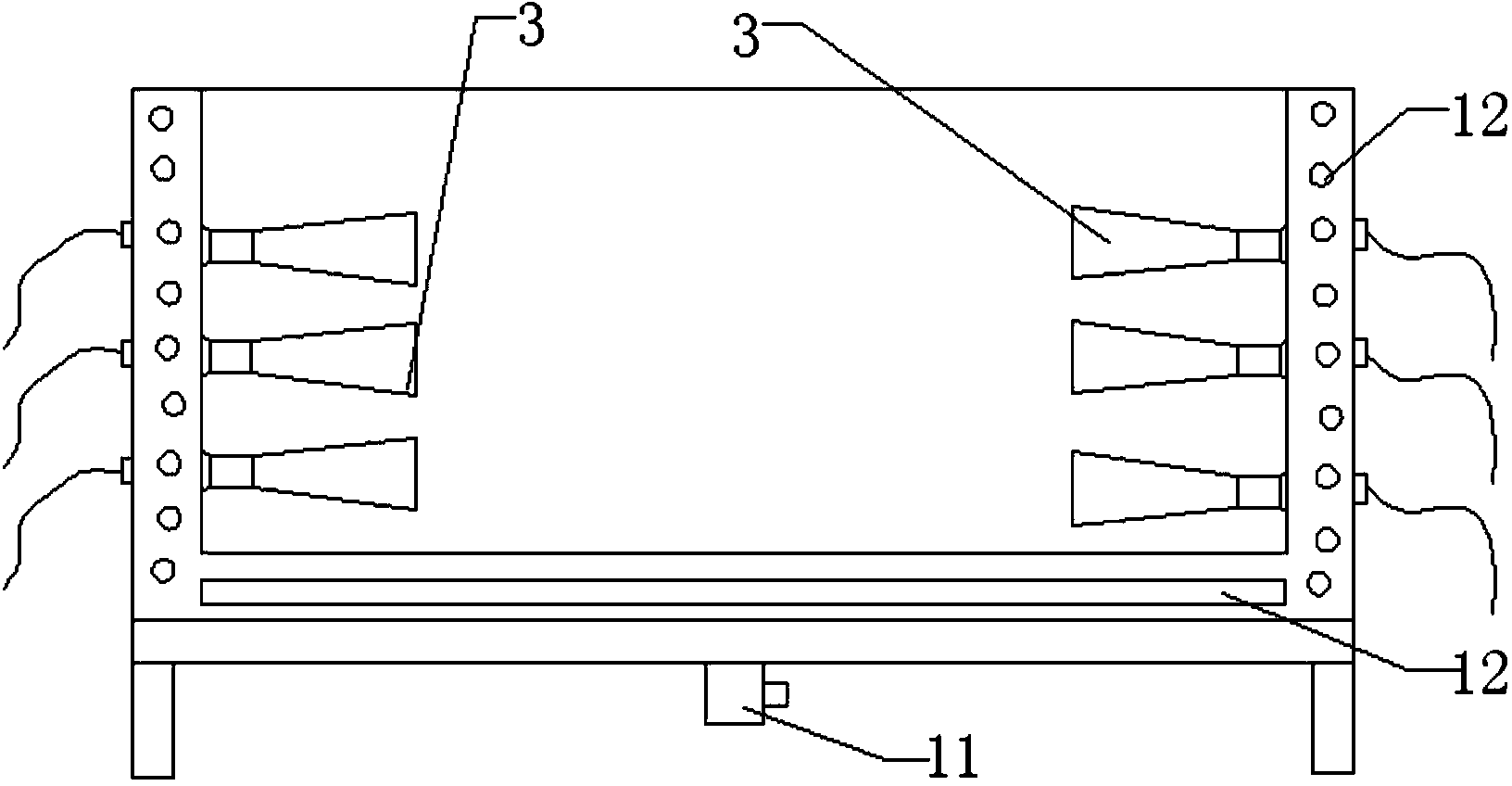

[0037]The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0038] like figure 1 , 2 , 3 shows an anodic oxidation cell of a strip-based aluminum alloy profile, the anodic oxidation device includes an electrolytic cell body 1, a cathode conductive device 2 and an anode conductive device 3, and the cell edge end surface of the electrolytic cell body 1 has uniformly distributed The center of the bottom of the electrolytic cell body 1 has a liquid discharge port 11, and the port of the liquid discharge port 11 has a rotary valve. The side of the electrolytic cell body 1 and the inside of the bottom plate have a connected coil heat exchanger 12. The coil heat exchange The inlet and outlet of the device 12 are respectively arranged on two op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com